A CNC machining shop in Suzhou was losing $12,000 per month to downtime—all because of their linear guide rails. The shop’s 5-axis machining centers, which cut aluminum auto parts, were shutting down every 2-3 weeks for slider replacements. The rails, a budget brand, were wearing out in 8-10 months, and each repair took 4 hours. After switching to Jingpeng’s linear guide rails and implementing our maintenance plan, the same machines now run 16-18 months between rail changes, with downtime cut to just 1 day per quarter.

For CNC shops, linear guide rails aren’t just components—they’re productivity drivers. The difference between a rail that lasts 8 months and 18 months comes down to three things: smart selection, proper installation, and proactive maintenance. We’re sharing the lessons we’ve learned from optimizing 100+ CNC shops, with actionable steps to boost your rail life and cut downtime.

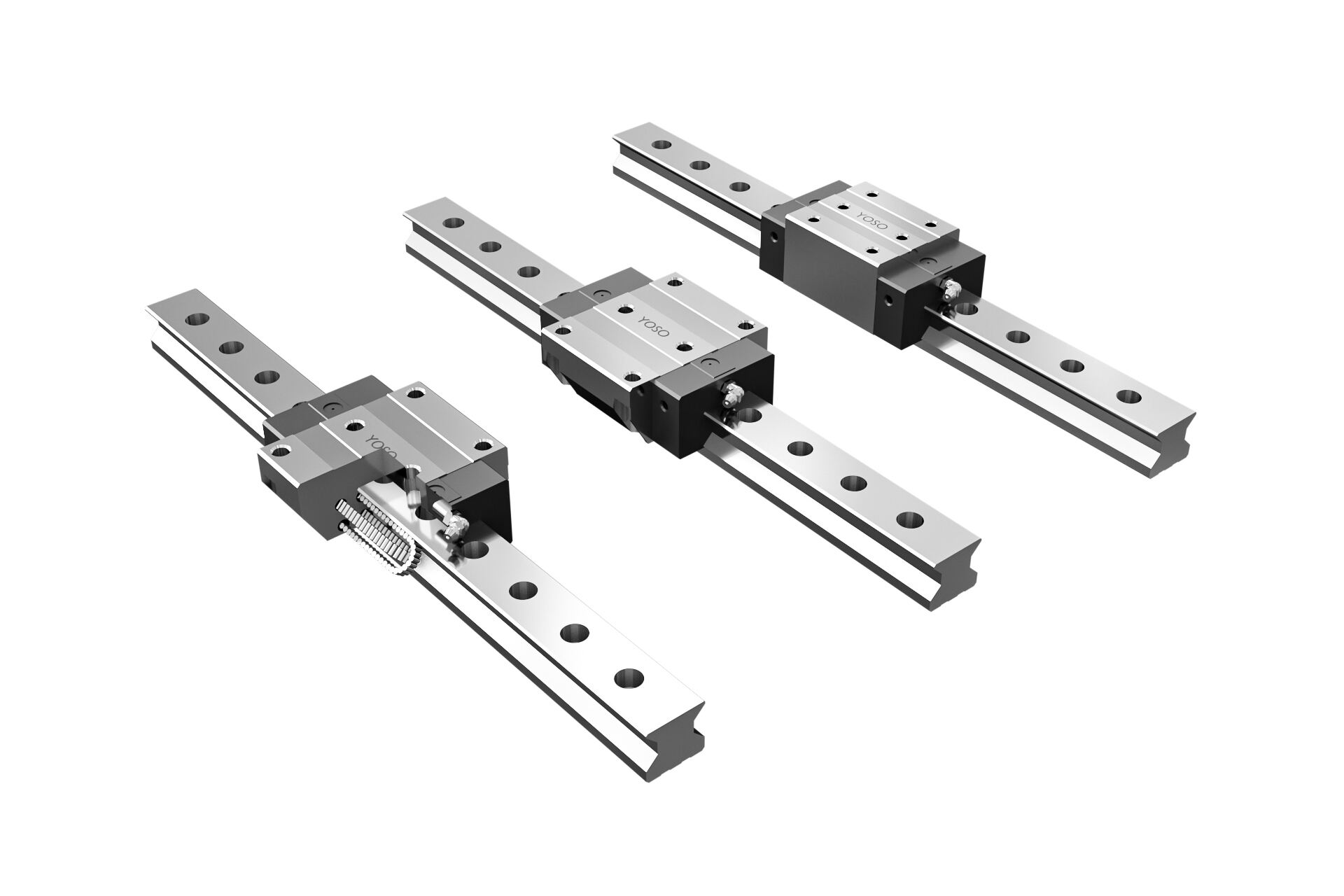

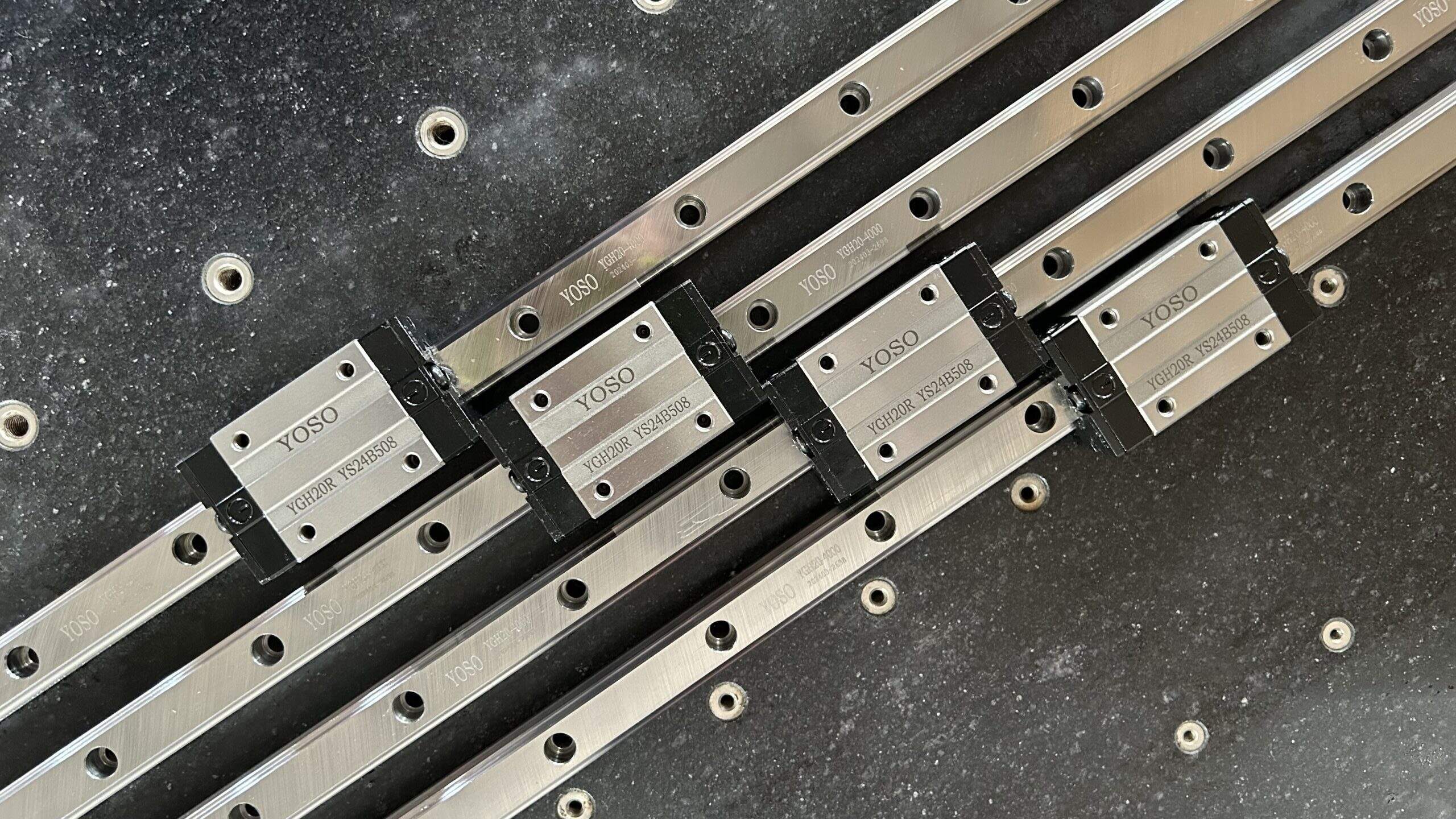

Alibaba Linear Guide Top Ranking

Step 1: Stop Buying "CNC-Grade" Rails—Choose by Load & Speed

Most CNC shops fall for the "CNC-grade" marketing hype, but that label means nothing without matching load and speed. A mold shop in Ningbo bought "high-precision" rails for their engraving machine, only to have them fail in 6 months. The issue? The rails were rated for 1m/s speed, but the engraver ran at 3m/s—causing the steel balls to overheat and deform.

Our load-speed matching formula takes the guesswork out:

Required Dynamic Load (kN) = (Machine Weight + Cutting Force) × 1.5 Safety Factor. For the Ningbo shop, we recommended high-performance YGH35 rails (rated for 3.5m/s and 42kN dynamic load). Two years later, the rails still have less than 0.005mm wear.

CNC Rail Selection Chart: CNC ApplicationTypical SpeedRecommended Rail SeriesService Life ExpectancyPrecision Engraving (Mold)2-4m/sHigh-Speed Precision Series18-24 monthsHeavy-Duty Milling (Steel)0.5-1.5m/sHeavy-Load Durable Series24-36 monthsSheet Metal Cutting (Plasma)1-2m/sGeneral-Purpose High-Stability Series15-20 months

Step 2: Installation Mistake That Kills Precision—Bolt Tightening Order

A 3-axis milling shop in Qingdao was frustrated with inconsistent part tolerances: parts cut in the morning were within ±0.01mm, but by afternoon, they’d drift to ±0.03mm. Our team checked the linear guide rails and found the issue—technicians were tightening the mounting bolts from left to right, causing the rail to bow slightly as it heated up.

We trained their team on the diagonal tightening method: start with the center bolts, then move to the corners in a crisscross pattern, using a torque wrench set to the rail manufacturer’s specs (M10 bolts = 18-20N·m). We also added heat-resistant shims under the rail to compensate for thermal expansion. The result? Tolerance drift dropped to ±0.005mm all day, and the shop’s rework rate fell from 8% to 1.2%.

Pro Installation Trick: After tightening, slide the slider back and forth 10 times, then retighten the bolts—this releases any stress in the rail.

Step 3: Maintenance Schedule That Doubles Rail Life

The biggest myth about linear guide rails is "lubricate once a week." A automotive parts shop in Changsha followed this rule but still had rails wearing out every 10 months. The problem? They were using too much grease—0.8ml per injection instead of the recommended 0.3ml. Excess grease trapped metal chips and dust, acting like sandpaper on the raceway.

We created a custom maintenance schedule based on their usage (16 hours/day, 6 days/week) and environment (moderate dust from aluminum cutting):

-

Daily: Wipe rail surface with a lint-free cloth; check for abnormal noise.

-

Every 5 Days: Inject 0.3ml of lithium complex grease (NLGI 2) per slider; blow out dust with low-pressure air.

-

Monthly: Check bolt torque; measure rail straightness with a dial indicator.

-

Quarterly: Disassemble dust covers; clean raceways with degreaser (for heavy dust).

After 18 months, the shop’s rail life extended to 22 months, and lubricant costs dropped by 50%.

Step 4: Early Warning Signs to Fix Before Failure

Most rail failures don’t happen overnight—they give warning signs weeks in advance. Here’s what to watch for, based on our work with 100+ CNC shops:

-

Abnormal Noise: A high-pitched squeal means insufficient lubrication; a grinding sound means metal chips in the raceway. Stop the machine immediately—running it will cause permanent damage.

-

Increased Slider Resistance: If pushing the slider feels "sticky," check for grease buildup or bent rail. Clean the raceway and reapply grease first—if that doesn’t help, the rail may need straightening.

-

Precision Drift: If parts start out of tolerance but the cutting tool is sharp, measure the rail’s straightness. A 0.01mm deviation in the rail = 0.01mm deviation in the part.

Jingpeng’s CNC Linear Guide Rail Solution: More Than Just Rails

We don’t just sell linear guide rails—we optimize your CNC shop’s productivity. Our CNC Rail Optimization Package includes:

-

Free on-site assessment of your machines, load, and environment.

-

Custom rail selection with load-speed calculations and 3D models.

-

On-site installation training for your technicians.

-

Quarterly check-ins to adjust maintenance schedules as needed.

If your CNC machines are losing precision or downtime is eating into profits, it’s time to stop replacing rails and start optimizing them. Jingpeng Machinery has technical teams in Shanghai, Turkey, and Poland—we can be on your shop floor within 48 hours to diagnose your issues. Contact us today for a free rail life assessment.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ