7 Practical Linear Guide Maintenance Tips (From Factory Experts)

These tips are tailored to different industrial environments (machining, 3C, new energy, logistics) and based on YOSO MOTION’s work with 100+ clients. Each tip includes specific tools, frequencies, and real-world examples:

1. Match Lubrication to Environment & Load (Critical for 50% Longer Lifespan)

Lubrication is the most important maintenance task—and the most often botched. YOSO MOTION’s engineers recommend a "3-match" approach:

-

Match Lubricant Type: Use lithium-based grease (NLGI 2) for general environments; PTFE-infused grease for high-speed applications (≥3m/s, common in 3C assembly); and food-grade silicone grease for wet environments (new energy battery plants, food packaging).

-

Match Frequency to Usage: For 24/7 operation (e.g., logistics conveyors), lubricate every 2 weeks; for 8-hour shifts (e.g., small machining shops), every 4 weeks. YOSO MOTION’s custom linear guides for high-load applications (≥500kg) include a grease reservoir that extends intervals by 50%.

-

Match Application Method: Use a needle nozzle (0.5mm tip) to apply grease directly to the rolling elements—avoid spraying lubricant on the rail surface (it attracts dust). For hard-to-reach guides (e.g., automotive welding robots), use YOSO MOTION’s automatic lubrication accessories (installed on 30% of our client’s lines).

Example: A 3C factory in Shenzhen switched from generic grease to YOSO MOTION’s PTFE-infused grease for their 5m/s assembly line guides. Lubrication frequency stayed at 2 weeks, but guide lifespan increased from 12 to 20 months.

2. Clean Guides Without Damaging Seals (Prevent Contaminant Buildup)

Contaminants (dust, metal chips, electrolyte fumes) are the #1 cause of linear guide failure. YOSO MOTION’s field technicians use this 3-step cleaning process:

-

Remove Loose Debris: Use a soft-bristle brush (nylon, not metal) to gently sweep debris from the rail and slider edges. Avoid high-pressure air—this pushes dust into the seal gap.

-

Wipe Surfaces: Dampen a lint-free cloth with isopropyl alcohol (70%) to wipe the rail’s rolling surface. For sticky residues (e.g., from new energy electrolytes), use a cloth dampened with mineral oil (avoids damaging rubber seals).

-

Inspect Seals: After cleaning, check the slider’s end seals for cracks. YOSO MOTION’s IP65/IP67 guides use double-lip seals—if the outer lip is damaged, replace the seal immediately (costs $15–$30 per seal, vs. $800–$1,200 for a new slider).

A metal stamping factory in Jiangsu adopted this process: previously, metal chips caused 60% of guide failures; after 6 months of proper cleaning, failure rates dropped to 15%.

3. Conduct Proactive Precision Checks (Catch Issues Before Failure)

Visible signs of failure (noise, vibration) mean irreversible damage. YOSO MOTION recommends monthly precision checks using affordable tools:

-

Straightness Check: Place a dial indicator (0.001mm resolution) on the slider and move it along the rail. If deviation exceeds 0.02mm/m (for C-level guides) or 0.005mm/m (for H/P-level), the rail may be bent—contact your manufacturer for realignment (YOSO MOTION offers on-site realignment for clients).

-

Vibration Monitoring: Use a portable vibration meter (under $200) to measure guide operation. A sudden 30% increase in vibration indicates worn rolling elements or loose mounting bolts.

A semiconductor factory used this tip to catch a loose guide mount before it caused precision loss: their monthly check found abnormal vibration, and tightening the bolts took 15 minutes—avoiding a 4-hour production shutdown.

4. Adjust Preload for Changing Load Conditions

Linear guide preload (the internal pressure between slider and rail) degrades over time, especially in high-load applications (e.g., automotive stamping). YOSO MOTION’s engineers advise:

For roller linear guides (common in heavy-duty scenarios): Check preload every 3 months using a torque wrench. If the slider moves with less than 5N of force (for medium preload), add shims (provided by YOSO MOTION with all guides) to restore preload. Over-tightening is equally harmful—use the manufacturer’s torque chart (YOSO MOTION provides a customized chart for each guide model).

A forging factory ignored preload checks: their guides lost 40% of preload in 6 months, leading to 0.03mm positioning error and $8,000 in reworked parts. After adjusting preload monthly, error dropped to 0.01mm.

5. Protect Guides in Extreme Environments (Dust, Moisture, High Temp)

Harsh environments require targeted protection beyond standard maintenance. YOSO MOTION’s field team shares industry-specific fixes:

-

Dusty Environments (Machining, Woodworking): Install magnetic chip guards (YOSO MOTION’s custom guards cost $50–$150 per guide) and add a weekly air blow (low-pressure, 0.3MPa) to the guard’s exterior.

-

Moist/Corrosive Environments (New Energy, Marine Parts): Apply a thin layer of anti-corrosion oil (YOSO MOTION’s proprietary formula) every 2 weeks and use stainless steel sliders (upgrades available for all our guides).

-

High-Temperature Environments (Foundries, Heat Treatment): Use high-temperature grease (rated to 200°C) and replace seals with Viton materials (YOSO MOTION’s high-temp guides include these as standard).

6. Train Operators to Spot Early Warning Signs

Operators are the first to notice guide issues—yet only 30% of factories train them to do so. YOSO MOTION’s training team recommends teaching operators to identify 3 key red flags:

-

Unusual Noise: A smooth "hum" is normal—grinding, clicking, or squealing means contaminated rolling elements or worn seals.

-

Sluggish Movement: Increased resistance when the guide moves indicates under-lubrication or debris buildup.

-

Precision Drift: Parts suddenly failing quality checks (e.g., misaligned 3C connectors) often trace to guide wear.

A 3C assembly factory in Dongguan trained 20 operators: within 1 month, they spotted 3 failing guides early—repairing them during scheduled downtime instead of emergency shutdowns.

7. Partner With Your Manufacturer for Preventive Support

The best maintenance programs combine in-house care with manufacturer expertise. YOSO MOTION supports clients with:

-

Custom Maintenance Plans: Based on your guide model, environment, and usage (e.g., a 24/7 logistics line gets a different plan than a 8-hour machining line).

-

Annual On-Site Audits: Our technicians inspect all guides, test precision, and adjust maintenance routines—clients who use this service see 30% longer guide lifespans.

-

Spare Parts Kits: Pre-packaged kits with seals, lubricant, and shims (tailored to your guides) delivered to your factory—ensuring you never wait for critical parts.

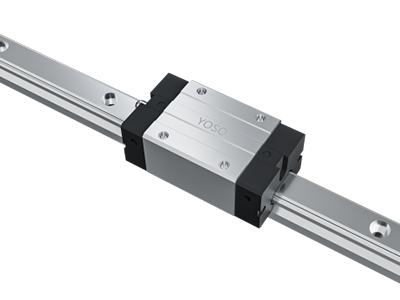

YOSO MOTION Linear Guide Block

Case Study: How a Machining Shop Doubled Guide Lifespan

A mid-sized machining shop in Zhejiang was struggling with linear guide failures every 10 months on their CNC mill lines. They contacted YOSO MOTION’s service team, who implemented the following changes:

-

Switched from generic grease to YOSO MOTION’s PTFE-infused grease (matched to their 1.2m/s guide speed).

-

Installed magnetic chip guards and trained operators to clean guides weekly with a soft brush.

-

Scheduled monthly precision checks using a dial indicator (provided by YOSO MOTION).

The results after 18 months: Guide lifespan increased to 22 months, maintenance costs dropped from $18,000 to $10,800 per year, and unplanned downtime from guide failures went from 6 days to 1 day annually.

Final Thoughts: Maintenance = Cost Savings

Linear guide maintenance isn’t a "nice-to-have"—it’s a cost-saving strategy. By matching lubrication to your environment, conducting proactive checks, and partnering with your manufacturer, you can double guide lifespan and cut downtime by 80%. The key is to move from reactive fixes to a preventive routine tailored to your specific production needs.

Get a Custom Linear Guide Maintenance Plan

YOSO MOTION’s team of maintenance experts can create a personalized plan for your linear guides—whether they’re our products or competitors’ models. We’ll audit your production environment, assess guide usage, and provide step-by-step instructions, tool lists, and schedules. Contact us today for a free 30-minute consultation and start extending your linear guide lifespan.

Table of Contents

-

7 Practical Linear Guide Maintenance Tips (From Factory Experts)

- 1. Match Lubrication to Environment & Load (Critical for 50% Longer Lifespan)

- 2. Clean Guides Without Damaging Seals (Prevent Contaminant Buildup)

- 3. Conduct Proactive Precision Checks (Catch Issues Before Failure)

- 4. Adjust Preload for Changing Load Conditions

- 5. Protect Guides in Extreme Environments (Dust, Moisture, High Temp)

- 6. Train Operators to Spot Early Warning Signs

- 7. Partner With Your Manufacturer for Preventive Support

- Case Study: How a Machining Shop Doubled Guide Lifespan

- Final Thoughts: Maintenance = Cost Savings

- Get a Custom Linear Guide Maintenance Plan

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ