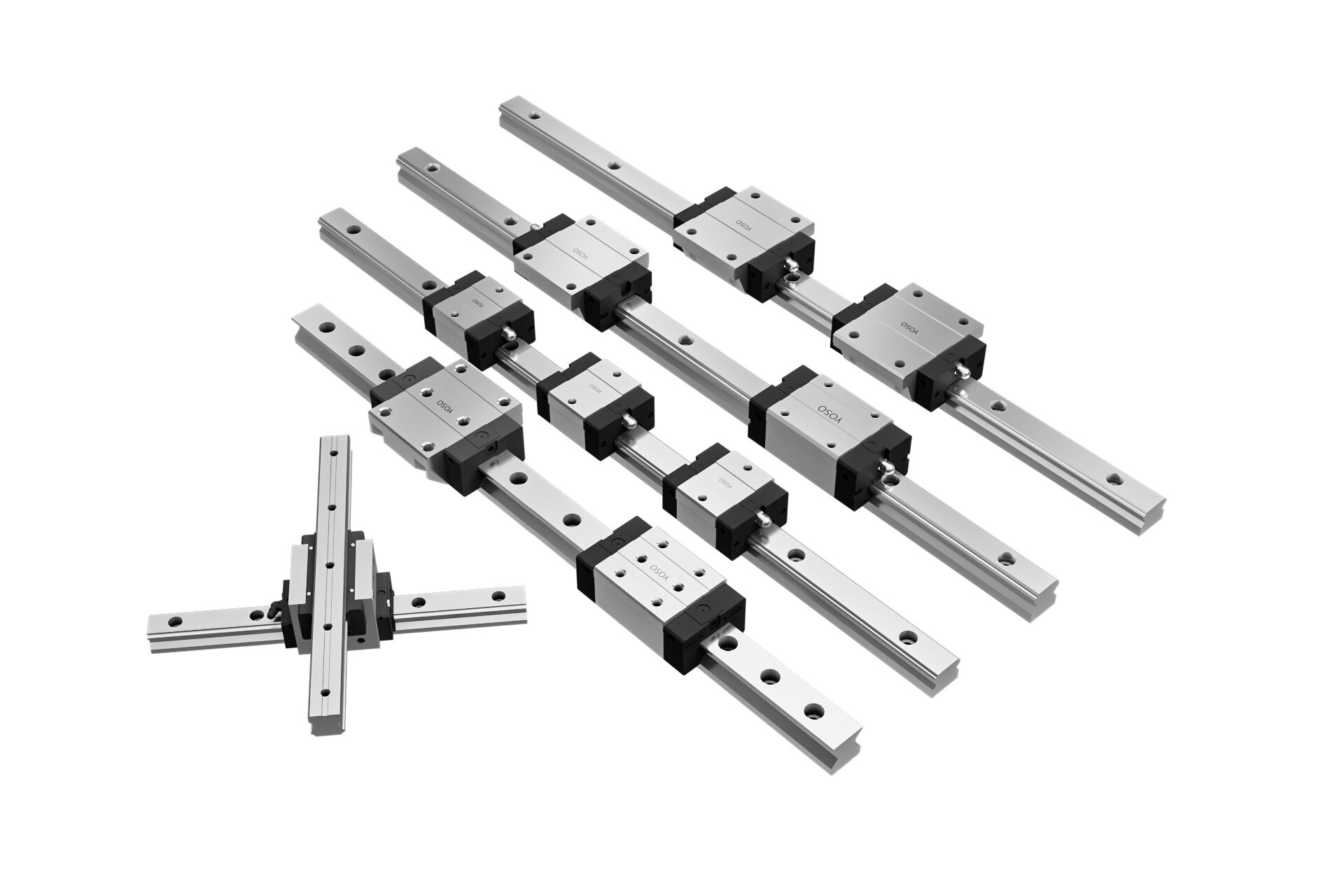

After 12 years fixing linear guides in everything from automotive welding shops to lithium-ion battery factories, my team at YOSO MOTION has seen every maintenance mistake imaginable. And let’s be clear: This isn’t some generic “lubricate regularly” guide. These are the gritty, shop-tested tricks we use to double guide lifespans for our clients—no fancy tools required, just common sense and lessons learned the hard way.

The #1 Myth That’s Killing Your Linear Guides (We See It Every Week)

Nearly every factory we visit follows the manufacturer’s “one-size-fits-all” maintenance schedule. You know the one: “Lubricate every two weeks with standard lithium grease.” That’s a death sentence for most guides—especially in dirty or high-speed environments.

Take the metal stamping shop in Guangzhou we helped last quarter. They were religiously following the default lubrication plan for their roller guides: lithium grease every 14 days. But their floor was thick with metal chips—those chips stuck to the over-lubricated rails like glue, turning into a grinding paste that chewed through sliders in 8 months flat. They were spending $12,000 a year on replacements, and their maintenance guy was frustrated because he “did everything the manual said.”

We fixed it with two tiny tweaks:

-

Switched to a PTFE-infused grease (it’s sticky enough to repel chips instead of attracting them—we use our own YOSO MOTION LM-300, but any industrial-grade PTFE works).

-

Stretched lubrication intervals to 21 days (less grease = less debris buildup).

Last week we checked in—those guides are still running strong at 16 months. Moral of the story: Maintenance has to fit your shop, not a textbook written in a corporate office.

5 Field-Tested Maintenance Hacks (No $10k Tools Needed)

You don’t need a vibration analyzer or a PhD in mechanical engineering to keep guides healthy. These tricks use tools you already have—or can grab for under $50 at your local hardware store.

1. Lubricate Like You’re Defending Against Debris (Not Just Greasing Parts)

Lubrication is 60% of maintenance success—and 90% of shops do it wrong. Here’s how we train our clients’ teams, based on their environment:

-

Dusty shops (machining, woodworking): Stop squirting grease all over the rail. Grab a needle nozzle (0.5mm tip—steal one from your grease gun kit) and shoot a pea-sized dollopdirectly into the slider’s lubrication port. Over-lubrication is worse than under-lubrication here—it turns your rail into a magnet for sawdust and metal chips.

-

High-speed lines (3C assembly, 5m/s+): Standard grease melts under friction. We tell clients to use PTFE-based grease—we had a Shenzhen phone factory switch, and their guide lifespan jumped from 10 months to 22.

-

Wet/corrosive areas (battery plants, marine parts): Add a thin coat of anti-rust oil (we use CRC 3-36, but any industrial grade works) to the rail edges every 4 weeks. And skip the WD-40—it dries out rubber seals faster than you’d think.

Pro tip: Mark your lubrication ports with colored tape—red for high-frequency (2 weeks), blue for low (4 weeks). Our clients say this cuts operator confusion by 80%.

2. Clean Guides Without Blasting Them to Pieces

High-pressure air guns are the single biggest enemy of linear guide seals. I was at a Jiangsu forging shop last year, and the maintenance guy was using a 100psi air gun to blow chips off the rails. I asked him to pop open a slider—and sure enough, metal shavings were packed under the seals, grinding the滚珠 (balls) to a nub. Those guides were only 7 months old.

We taught his team our “soft clean” routine—it takes 2 minutes per guide, no air gun needed:

-

Brush loose debris with a nylon bristle brush (the kind you use to clean parts—metal brushes scratch rails).

-

Wipe the rail with a lint-free cloth dampened with 70% isopropyl alcohol. Wipe with the rail’s length, not across it—this keeps debris from getting pushed into seal gaps.

-

Pinch the slider’s end seals between your thumb and finger. If they feel hard, cracked, or sticky, replace them immediately. Seals cost $15–$30 each—way cheaper than a $800 slider.

Six months later, that shop’s guide failure rate dropped from 6 per quarter to 1. Worth the 2 extra minutes per guide? Absolutely.

3. Check Preload With a “Hand Test” (No Torque Wrench Required)

Preload—the tension between slider and rail—fades over time, especially in heavy-load jobs like automotive welding. A loose guide causes precision drift (I’ve seen weld spots off by 0.03mm because of this) and premature wear.

You don’t need fancy tools to test it. Here’s the “hand test” we teach every client:

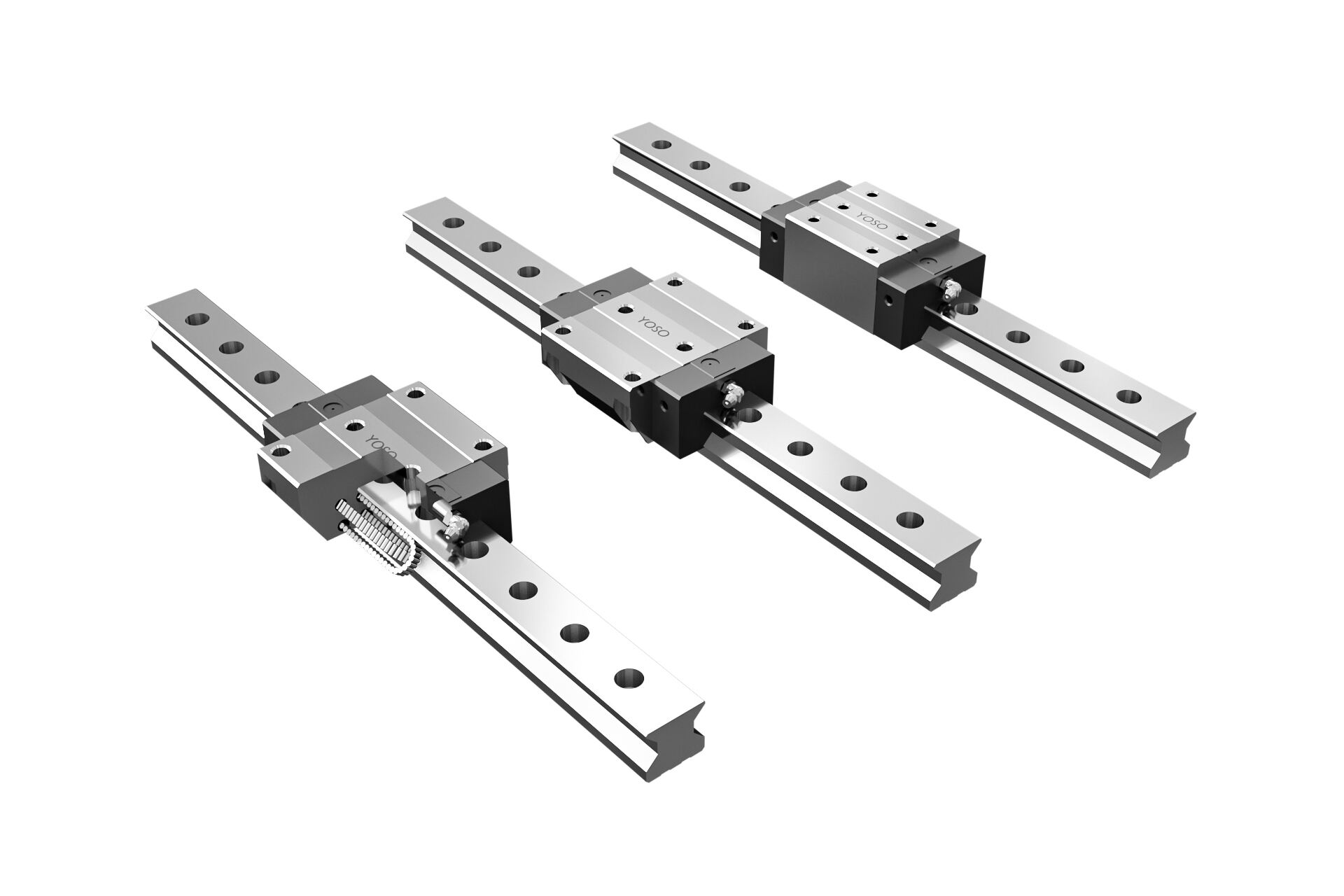

Grab the slider with both hands and try to wiggle it side-to-side. If you feel even the tiniest play (more than 0.01mm—you’ll know it when you feel it), add a shim between the slider and mounting plate. We include 3 sizes of shims with every YOSO MOTION guide—most manufacturers do the same, so check your spare parts bin.

A Zhejiang forging shop skipped this check and paid for it: Their guides lost preload, and they had to rework 500 engine brackets—$10k in losses. Now they do the hand test every shift change, and they haven’t had a precision issue since.

4. Train Operators to Spot “Death Rattles” (Before It’s Too Late)

Operators are your first line of defense—yet 90% of factories don’t train them to spot guide issues. Last year, I was at a Wuhan automotive plant, and the line operator mentioned, “That guide’s been making a clicking noise for a week.” We shut it down, opened the slider, and found a cracked ball retainer. Fixing it took 30 minutes during a break—avoiding a 3-hour shutdown.

Teach your operators to watch for these three “death rattles”:

-

Noise: A smooth hum is fine. Grinding, clicking, or squealing? Stop the machine immediately—debris is in the rolling elements.

-

Sluggishness: If the guide feels “sticky” when moving, don’t force it. It’s either under-lubricated or the rail is bent.

-

Precision Drift: If parts suddenly start failing QA (e.g., 3C connectors misaligning), check the guide before blaming the tool. We’ve seen this save shops $5k+ in rework.

A Dongguan 3C shop trained 15 operators on these signs. Within a month, they caught 2 failing guides early—fixing them during lunch breaks instead of losing production time.

5. Stop Googling “Maintenance Tips” and Call Your Manufacturer

Generic online guides don’t know your shop’s quirks—like how your guides sit 10 feet from a welding torch, or how much dust your woodworking machines kick up. That’s why we send our techs to audit client floors for free—last year, we visited 120 shops, and 80% had easily fixable issues we caught in 15 minutes.

Take the battery factory in Changsha we helped: Their guides were failing every 9 months, and they thought it was “bad quality.” Our tech showed up, looked at the line, and noticed the guides were mounted on uneven plates—causing one side of the slider to wear faster. We realigned the plates (1-hour fix) and adjusted their lubrication schedule. Their guide lifespan jumped to 20 months.

Ask your manufacturer for three things—any reputable brand (like YOSO MOTION) will say yes:

-

A custom maintenance plan based on your environment (not a generic PDF).

-

A spare parts kit with seals, shims, and grease tailored to your guide model.

-

Annual on-site audits—this alone can double your guide lifespan.

Final Thought: Maintenance Isn’t a Chore—It’s Profit

I’ve never met a shop owner who wants to spend money on linear guide replacements or downtime. But I’ve met plenty who treat maintenance like an afterthought—until a guide fails and costs them $10k in a single day.

The truth is: A 10-minute daily check, the right grease, and a team that knows what to look for can double your guide lifespan and cut downtime by 80%. It’s not rocket science—it’s just the lessons we’ve learned fixing hundreds of shops like yours.

If you’re tired of surprise guide failures, let’s talk. Our YOSO MOTION team will come to your shop (or do a virtual audit) for free. We’ll walk your floor, point out the easy fixes, and build a maintenance plan that fits your schedule—not ours. No sales pitch, just practical advice from guys who’ve been in your shoes.

Contact us today to book your audit. Let’s stop wasting money on avoidable failures.

Table of Contents

- The #1 Myth That’s Killing Your Linear Guides (We See It Every Week)

-

5 Field-Tested Maintenance Hacks (No $10k Tools Needed)

- 1. Lubricate Like You’re Defending Against Debris (Not Just Greasing Parts)

- 2. Clean Guides Without Blasting Them to Pieces

- 3. Check Preload With a “Hand Test” (No Torque Wrench Required)

- 4. Train Operators to Spot “Death Rattles” (Before It’s Too Late)

- 5. Stop Googling “Maintenance Tips” and Call Your Manufacturer

- Final Thought: Maintenance Isn’t a Chore—It’s Profit

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ