For industrial equipment such as CNC machine tools, automated assembly lines, and robotic workstations, linear guide rails are core components that determine motion precision. However, many enterprises ignore the importance of correct installation and regular maintenance, leading to premature wear of linear guide rails, reduced precision, and even equipment downtime. This article focuses on the key points of linear guide rail installation, common maintenance methods, and fault handling skills, helping you maximize the performance of linear guide rails and extend their service life.

1. Key Points of Linear Guide Rail Installation: Lay a Foundation for Precision

The installation quality of linear guide rails directly affects their motion accuracy and load-bearing capacity. Hasty installation often causes hidden dangers such as uneven force and trajectory deviation. The following steps and key points must be followed:

Before installation, first check the linear guide rail and its accessories (sliders, bolts, washers) for damage or deformation. Use a precision level to detect the flatness of the installation base—for high-precision linear guide rails, the flatness error should be controlled within 0.02mm/m. Then, clean the guide rail raceway, slider inner cavity, and installation base with anhydrous ethanol to remove oil stains, dust, and metal chips, avoiding abnormal wear caused by impurities during installation.

1.2 Positioning and Fixing: Ensure Accuracy

Place the linear guide rail on the installation base and align it with the positioning line. Use temporary fixing bolts to pre-fix the guide rail, and then use a dial indicator to detect the straightness of the guide rail—push the dial indicator along the guide rail length direction, and adjust the guide rail position until the straightness error is within the allowable range (C-grade ≤0.1mm/m, H-grade ≤0.05mm/m). After positioning, tighten the fixing bolts in a diagonal sequence to ensure uniform stress on the guide rail; the tightening torque should match the bolt specification (e.g., M6 bolts use 8-10N·m torque).

1.1 Pre-Installation Preparation: Check and Clean

1.3 Slider Installation and Run-In

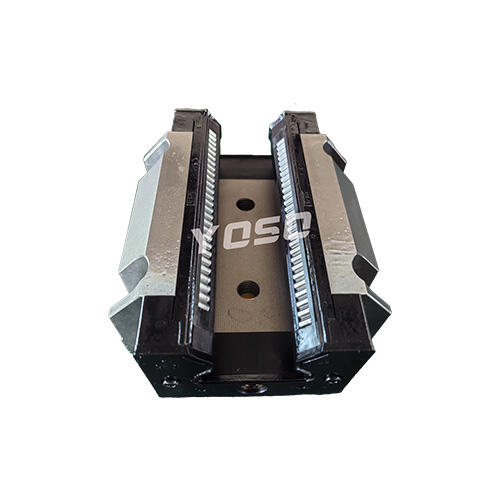

Apply a thin layer of lubricating grease (lithium-based grease is recommended) to the guide rail raceway, and then gently push the slider onto the guide rail—avoid brute force to prevent damage to the steel balls and raceway. After installing the slider, move it back and forth along the guide rail 5-10 times to ensure smooth motion without jamming. For multi-slider installation, ensure the parallelism between sliders (error ≤0.03mm/m) to avoid uneven load distribution.

1.4 Post-Installation Inspection

After installation, conduct a comprehensive inspection: use a torque wrench to recheck the tightening torque of all bolts; use a precision measuring instrument to test the motion accuracy and repeat positioning accuracy of the slider; observe whether the slider moves smoothly without abnormal noise. If any problems are found, adjust in time to avoid formal operation with faults.

Alibaba Linear Guide Five-Star Store

2. Regular Maintenance of Linear Guide Rails: Reduce Wear and Extend Life

Regular and scientific maintenance can reduce the wear rate of linear guide rails by more than 60% and extend their service life from 50,000 hours to more than 100,000 hours. The core maintenance work includes lubrication, cleaning, and regular inspection.

2.1 Scientific Lubrication: The "Protective Film" of Raceway

Lubrication is the key to reducing friction between linear guide rail steel balls and raceways. Choose lubricating grease or lubricating oil that matches the working conditions: for high-speed linear guide rails (speed >3m/s), use low-viscosity lubricating oil (ISO VG32-VG68); for heavy-load linear guide rails, use high-viscosity lithium-based grease. The lubrication frequency should be adjusted according to the working environment: in clean environments, lubricate once every 100 hours; in dusty or high-humidity environments, shorten to once every 50 hours. When lubricating, inject the lubricant into the oil injection hole until it overflows from the slider gap, ensuring full lubrication of the raceway.

2.2 Timely Cleaning: Prevent Impurity Invasion

Impurities such as dust, cutting fluid, and metal chips are the main causes of abnormal wear of linear guide rails. After daily use, clean the guide rail surface with a clean lint-free cloth; for the slider dust cover, regularly disassemble and clean it to remove the impurities accumulated at the seal. In harsh environments such as machining workshops, install additional protective covers (such as telescopic steel covers) on the linear guide rails to isolate external impurities.

2.3 Regular Inspection: Discover Hidden Dangers in Advance

Establish a weekly and monthly inspection system: weekly check the lubricant level, slider motion smoothness, and dust cover integrity; monthly conduct in-depth inspection, including measuring the guide rail straightness, checking the bolt tightness, and detecting the slider clearance. If the slider has obvious clearance or the motion resistance increases, replace the slider in time; if the guide rail raceway is worn or scratched, repair it by grinding or replace the guide rail.

3. Common Faults of Linear Guide Rails and Handling Methods

Even with correct installation and maintenance, linear guide rails may have faults during long-term use. Mastering the following common fault handling methods can quickly restore equipment operation:

3.1 Slider Jamming or Abnormal Noise

Possible causes: insufficient lubrication, impurities in the raceway, or deformation of the guide rail. Handling method: first clean the guide rail and slider, then inject sufficient lubricant; if the noise still exists, check the guide rail straightness and slider damage, and replace the damaged parts if necessary.

3.2 Reduced Motion Precision

Possible causes: loose fixing bolts, wear of the raceway, or uneven installation base. Handling method: re-tighten the bolts in a diagonal sequence; measure the raceway wear with a precision instrument, and grind or replace the guide rail if the wear exceeds 0.01mm; re-level the installation base if necessary.

3.3 Premature Wear of Slider

Possible causes: incorrect lubricant type, excessive load, or harsh working environment. Handling method: replace the lubricant with a suitable type; check whether the load exceeds the linear guide rail’s rated load, and replace it with a heavy-duty model if necessary; add protective measures for harsh environments.

4. Conclusion: Installation and Maintenance Determine the Value of Linear Guide Rails

High-quality linear guide rails can only exert their maximum performance through correct installation and scientific maintenance. Neglecting these two links will not only waste the investment in high-precision components but also cause equipment downtime and affect production efficiency.

If you encounter problems in the installation, maintenance, or fault handling of linear guide rails, welcome to contact our professional technical team. We provide on-site guidance and customized maintenance plans to help you make the most of linear guide rails and create greater value for production.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ