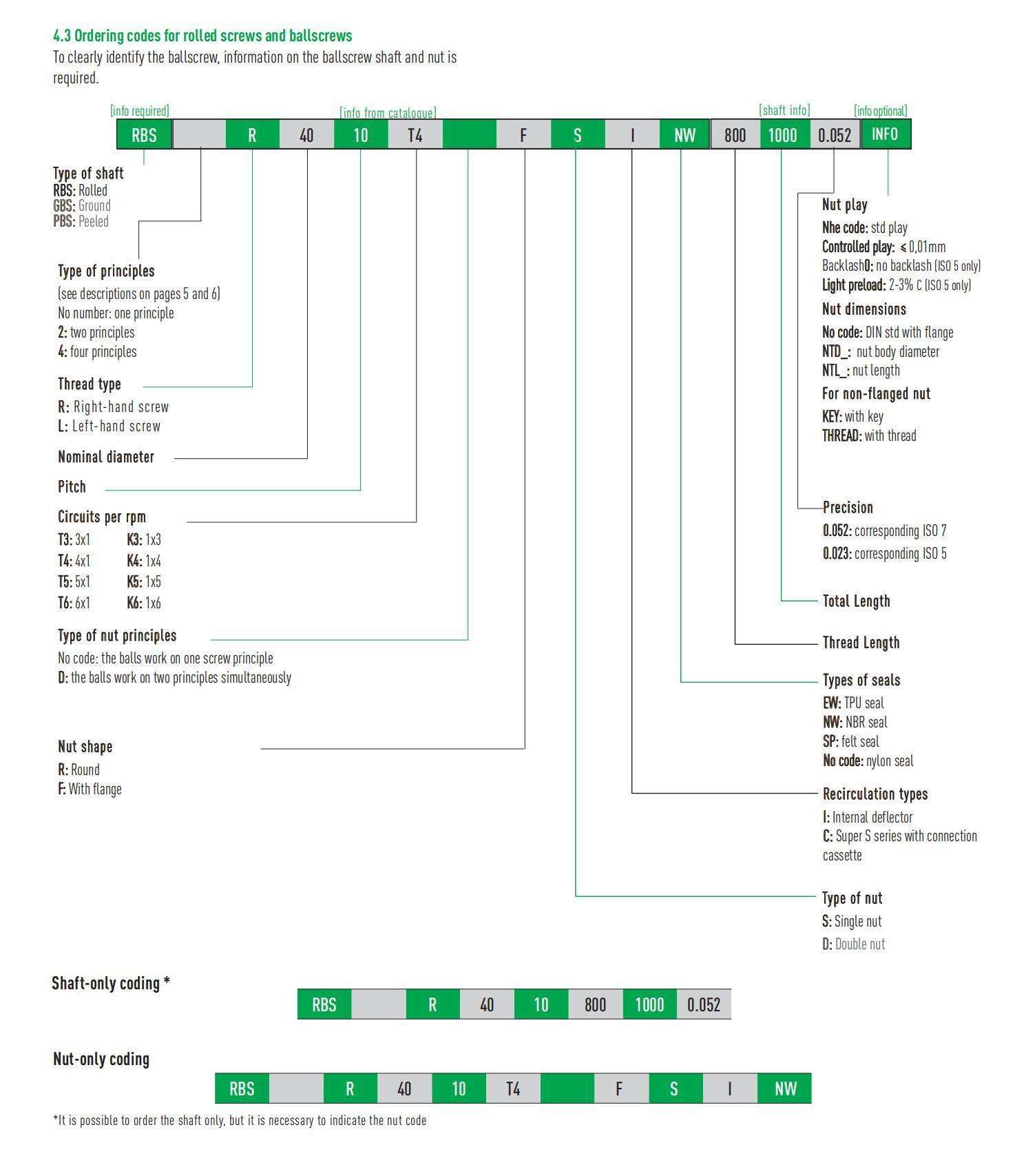

Model Meaning:

“R”: Indicates a right-hand-rotating ball screw.

“20”: Represents a nominal diameter of 20mm.

“5”: Refers to a 5mm lead, meaning the nut moves 5mm along the screw axis for each screw rotation.

“T3”: 3×1

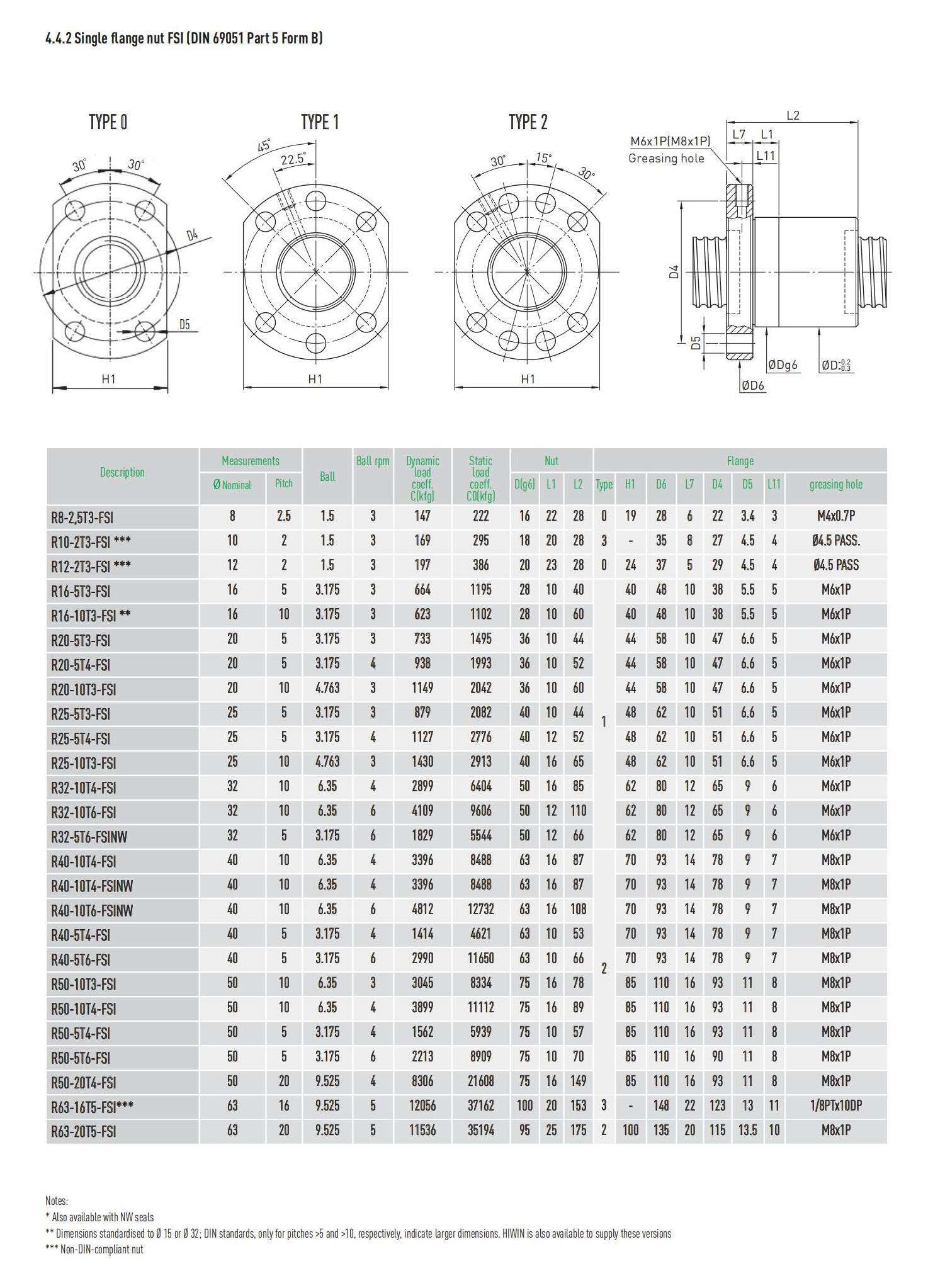

“FSI”: “F”: Flange-mounted nut, “S”: Single nut, and “I”: Internal recirculation.

HIWIN R20-5T3-FSI ball screws are not only compact in structure, but also easy to maintain on a daily basis. Their high surface finish and excellent rolling track reduce the wear rate and extend the maintenance cycle. Users only need to regularly clean the screw surface and add grease to maintain the low friction characteristics of the screw. Especially in environments with a lot of dust or frequent changes in temperature and humidity, it is recommended to install dust-proof devices, such as bellows or dust covers, to further increase the service life. In actual use, if abnormal operation, increased noise or positioning deviation is found, the lubrication condition and preload should be checked in time. Good maintenance management not only helps to maintain equipment performance, but also avoids downtime losses caused by unexpected failures and improves overall production efficiency. The easy maintenance characteristics of FSI are an advantage that cannot be ignored in modern factory automation environments.

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved