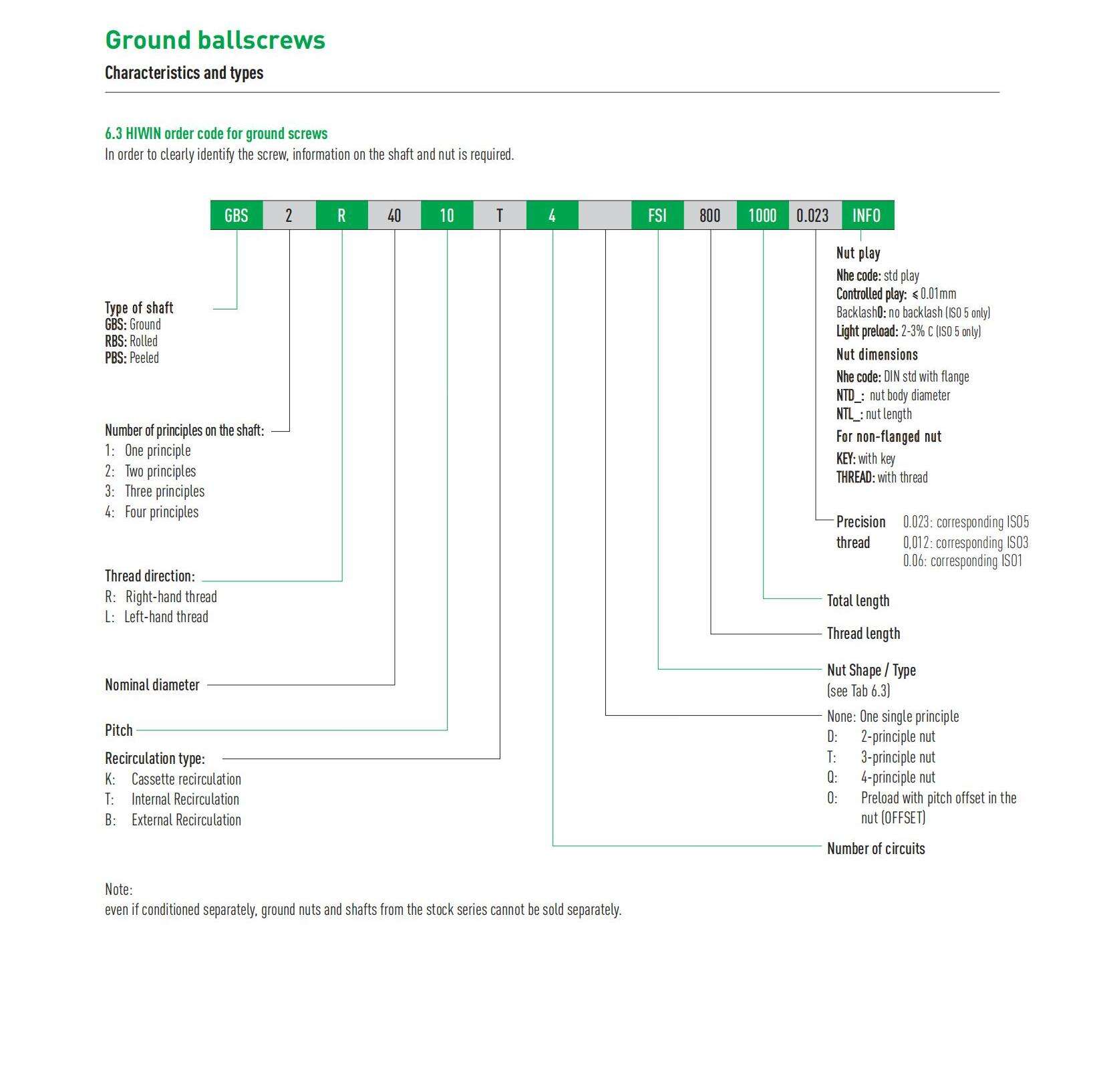

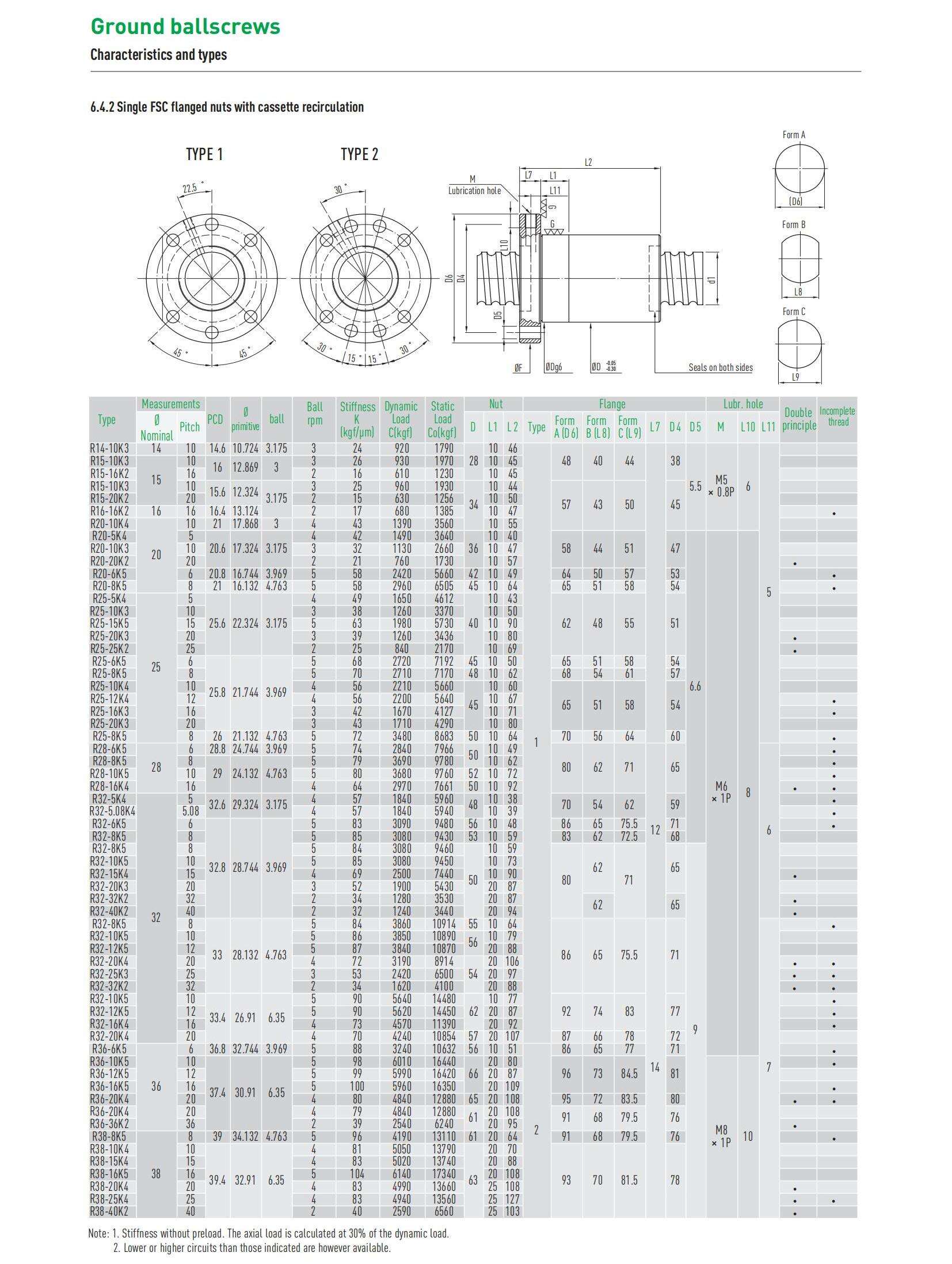

HIWIN R14-10K3-FSC Model Analysis

R14: Indicates a nominal screw diameter of 14mm. This is a core dimensional parameter of a ball screw, determining its load capacity and rigidity.

10: Lead is 10mm, which refers to the distance the nut moves axially per screw rotation. This lead is suitable for applications with medium speeds and loads, such as linear drives in automated equipment.

K3: Indicates a ball recirculation system of 3 turns. The number of turns affects the load distribution and lifespan of the screw. More turns increase the dynamic load capacity but also increases the torque requirement.

FSC: Nut construction code, specifically meaning:

F: Features a flange mounting surface for easy attachment to the equipment base;

S: Single nut design for a compact structure;

C: Utilizes the Super S series recirculation system, offering low noise and high smoothness, suitable for high-speed applications.

The most prominent features of the HIWIN R14-10K3-FSC ball screw are its high precision and low friction. It utilizes rolling contact between the balls, the screw, and the nut, replacing traditional sliding friction. This increases transmission efficiency to over 90%, reducing friction compared to conventional screws. Furthermore, precision grinding technology employed during machining minimizes lead error, ensuring precise operation. Furthermore, its structural design reduces wear and tear, extending its lifespan by 3-5 times that of conventional screws. It also simplifies maintenance during daily use, making it suitable for mechanical devices requiring stable operation.

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved