Product Information | |

Product Name |

THK DIK2505-6 Ball Screw |

Material |

Bearing steel, harden steel, chrome steel, stainless steel |

Accuracy |

C3 C5 C7 C10 |

Application |

Precision CNC machine tools Semiconductor manufacturing equipment Electronic component manufacturing and testing equipment Precision measuring instruments Industrial robots Medical equipment Laser processing equipment Factory automation and precision assembly |

Features |

Compact Preload Offset preload Deflector type Slim nut Precision positioning (ball screw) |

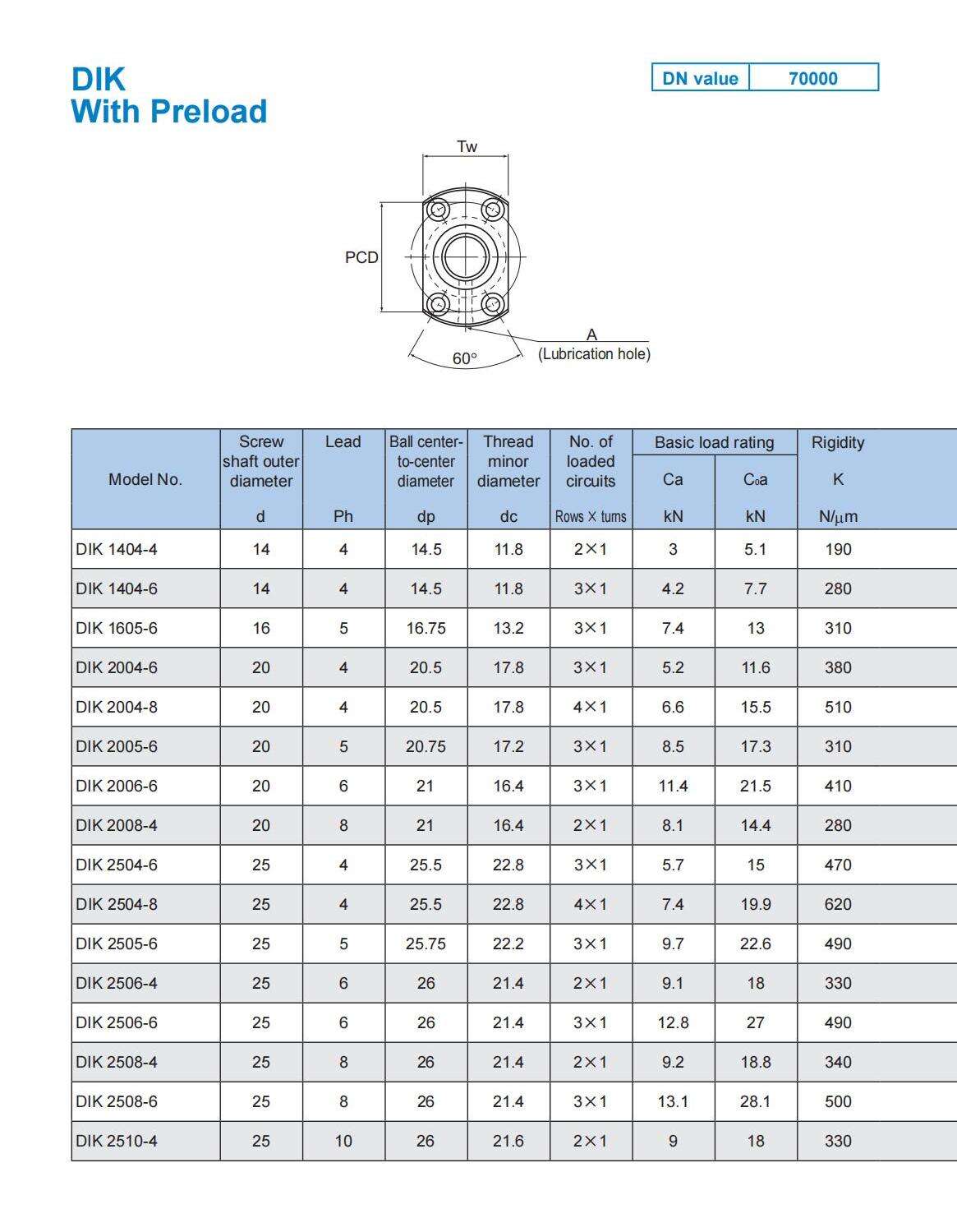

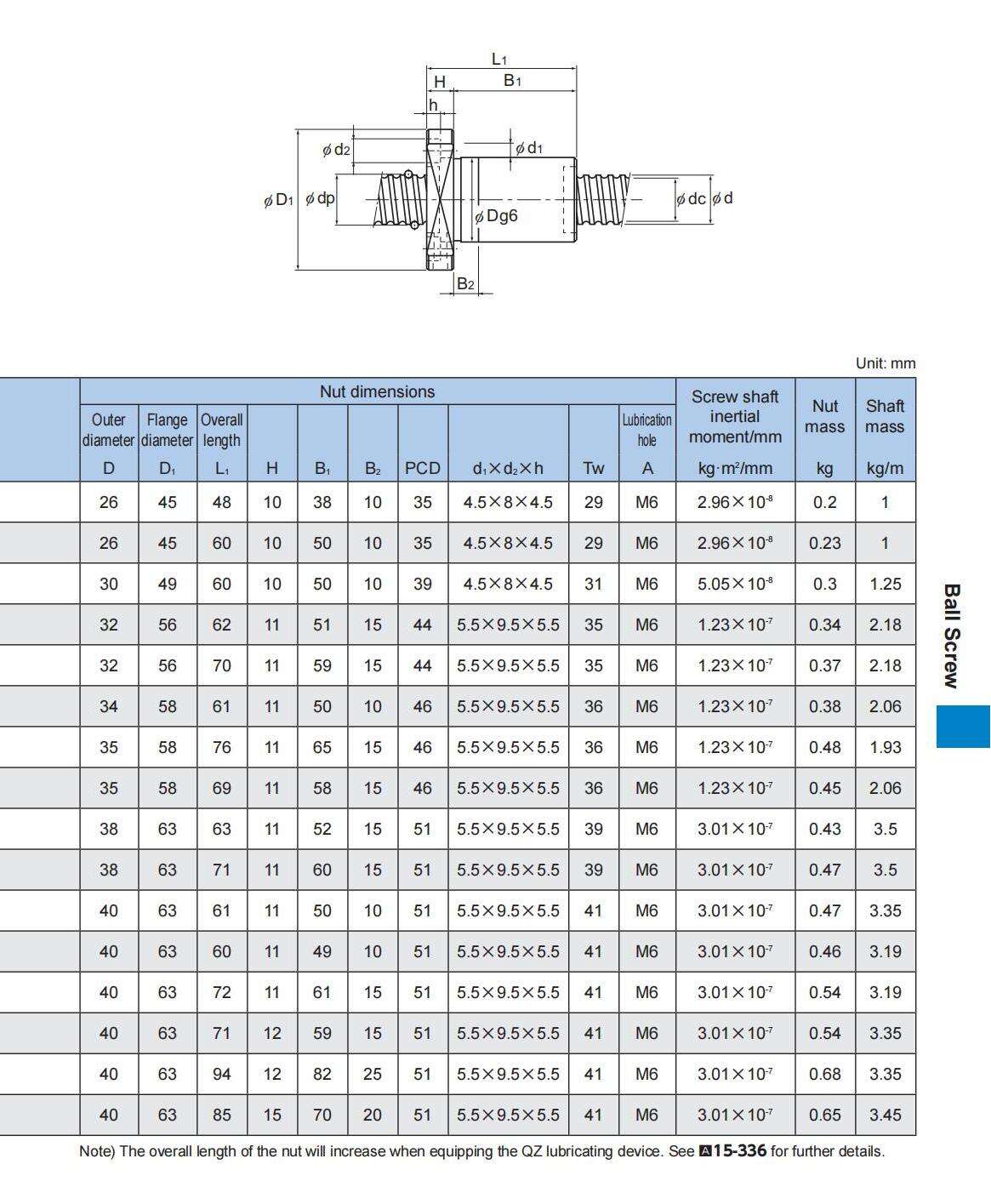

Model No. |

DIK 1404-4 DIK 1404-6 DIK 1605-6 DIK 2004-6 DIK 2004-8 DIK 2005-6 DIK 2006-6 DIK 2008-4 DIK 2504-6 DIK 25048 DIK 2505-6 DIK 2506-4 DIK 2506-6 DIK 2508-4 DIK 2508-6 DIK 2510-4 DIK 2805-6 DIK 2805-8 DK 2806-6 DK 2810-4 DIK 3204-6 DIK 3204-8 DIK 3204-10 DIK 3205-6 DIK 3205-8 DIK 3206-6 DIK 3206-8 DIK 3210-6 DIK 3212-4 DIK 3610-6 DIK 3610-8 DIK 3610-10 DIK 4010-6 DIK 4010-8 DIK 4012-6 DK 4012-8 DIK 4016-4 DIK 5010-6 DIK 5010-8 DIK 5010-10 DIK 5012-6 DIK 5012-8 DK 5016-4 DIK 5016-6 DIK 6310-8 DIK 6312-6 DIK 6312-8 |

Our services |

According to drawings or samples for our customers to manufacture products. |

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

Delivery time |

3~7 days for sample order, 15~20 days for bulk order. Depends on the actual shipping situation. |

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved