In industries where heavy loads, micron-level precision, and long-term reliability are non-negotiable, planetary roller screws have emerged as the backbone of high-performance linear motion systems. Unlike traditional ball screws or trapezoidal screws, these engineered components leverage line contact between rollers and the screw shaft to deliver unmatched load capacity, durability, and accuracy—making them indispensable in sectors where failure or inconsistency carries significant costs. From aerospace to medical devices, planetary roller screws solve complex motion challenges, enabling innovations in automation and machinery design. This article explores their real-world applications, technical适配性, and why they’re the top choice for demanding workflows.

Why Planetary Roller Screws Outperform Traditional Alternatives in Specialized Applications

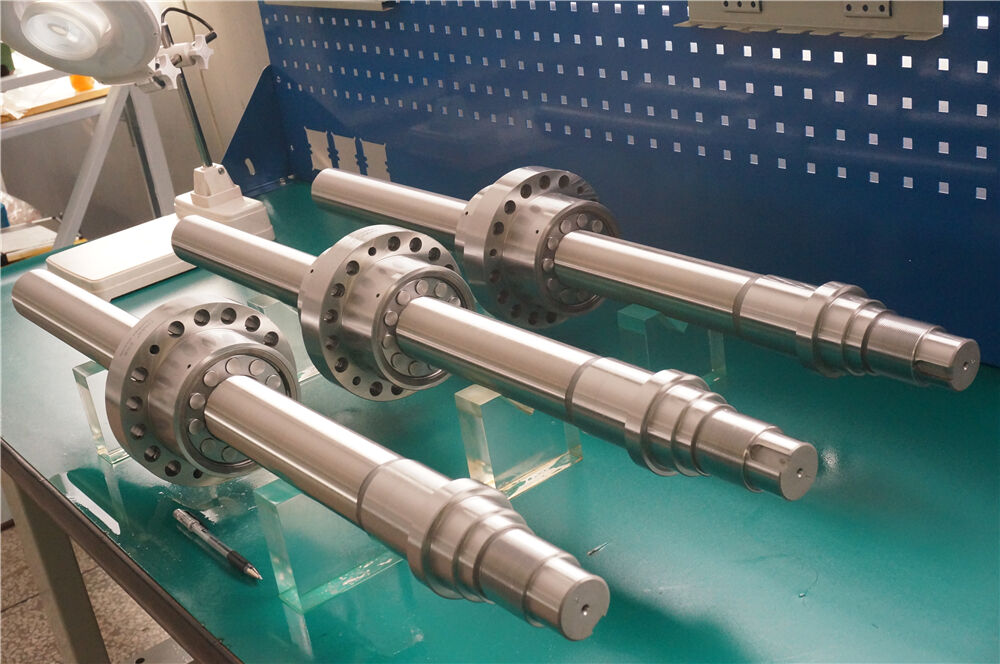

The unique design of planetary roller screws—with multiple threaded rollers orbiting the screw shaft—addresses key limitations of conventional screws. Their ability to handle dynamic loads up to 1000kN, maintain precision over millions of cycles, and operate at high speeds without sacrificing stability makes them ideal for applications where performance margins are tight. Unlike ball screws (limited by point contact) or trapezoidal screws (low efficiency), planetary roller screws balance strength, precision, and speed—filling gaps in industries that demand nothing less than perfection.

Key Applications of Planetary Roller Screws Across Industries

Planetary roller screws are not a one-size-fits-all component; their versatility shines in specialized sectors where standard motion solutions fall short. Below are their most impactful applications, with insights into how they drive performance and compliance.

1. Aerospace & Defense: Reliability in Extreme Conditions

Aerospace and defense systems demand components that perform flawlessly in harsh environments—extreme temperatures, vibration, and high-pressure loads. Planetary roller screws are integral to critical systems like aircraft flap controls, landing gear actuation, and missile launcher positioning. Their high rigidity and shock resistance ensure precise movement even under fluctuating loads, while their extended service life (up to 15x longer than ball screws) reduces maintenance needs for aircraft and military equipment—where downtime is not an option. For example, in commercial jet flap systems, planetary roller screws enable smooth, incremental adjustments to optimize lift and drag, enhancing fuel efficiency and flight safety.

2. Heavy Machinery & Industrial Automation: Handling High Loads with Precision

In heavy machinery—such as injection molding machines, metal stamping presses, and hydraulic replacements—planetary roller screws excel at handling massive clamping forces and repetitive motion. Injection molding machines rely on them for precise mold closing and injection unit positioning, where load capacity and accuracy directly impact part quality. Unlike hydraulic systems, they eliminate fluid leakage risks and offer superior control over motion speed and position, reducing material waste and improving production consistency. In metalworking, they power CNC machine tool feed axes, delivering micron-level precision for complex components while withstanding the high torque and vibration of cutting operations.

3. Medical Devices: Precision & Sterility for Life-Saving Equipment

Medical devices require motion components that balance precision, quiet operation, and compliance with strict hygiene standards. Planetary roller screws are used in surgical robots, CT/MRI scanners, and drug delivery systems—applications where even minor errors can compromise patient safety. In robotic surgery, they enable delicate, controlled movements of surgical instruments, with repeat positioning accuracy down to ±0.005mm, supporting minimally invasive procedures. Their sealed design prevents particle generation and lubricant leakage, making them suitable for sterile environments like operating rooms. For CT scanners, they drive the smooth rotation of imaging components, ensuring clear, consistent scans while operating at low noise levels (below 60dB) to enhance patient comfort.

4. Semiconductor & Electronics: Micro-Precision for High-Tech Manufacturing

Semiconductor manufacturing demands ultra-precise motion control for processes like wafer handling, lithography, and chip assembly. Planetary roller screws deliver the micro-feeding capabilities (leads as small as 0.5mm) needed to position wafers and components with sub-micron accuracy. Their low particle emission and cleanroom compatibility make them ideal for Class 100 cleanrooms, where contamination can ruin entire batches of microchips. In lithography machines—critical to chip production—they ensure the precise alignment of light sources and wafers, directly influencing the density and performance of semiconductor devices.

5. Automotive & New Energy: Driving Efficiency in EVs and Heavy-Duty Vehicles

The automotive industry—especially electric vehicles (EVs)—relies on planetary roller screws for high-performance motion systems. They power EV electronic brake systems, active suspensions, and battery pack positioning, offering fast response times and high load capacity. In EV brakes, they enable rapid, precise actuation to enhance safety, while their durability aligns with the long service life expectations of electric vehicles. For wind turbine pitch control (a key new energy application), planetary roller screws adjust blade angles to optimize energy capture, withstanding outdoor conditions and cyclic loads for decades—reducing maintenance costs for wind farm operators.

Critical Considerations for Selecting Planetary Roller Screws for Specific Applications

Choosing the right planetary roller screw requires aligning its specifications with application demands. Below are key factors to prioritize:

-

Load Requirements: Calculate static/dynamic loads and impact forces to select a screw with adequate rated capacity. Aerospace and heavy machinery need higher load margins, while medical devices may prioritize precision over maximum load.

-

Precision & Lead: Match lead accuracy (KL5 to KL10 grades) to the application—semiconductor manufacturing needs ultra-fine leads, while heavy machinery may accept standard precision.

-

Environmental Conditions: Opt for corrosion-resistant materials (316 stainless steel) and sealed designs for harsh or sterile environments (aerospace, medical).

-

Maintenance Needs: Choose self-lubricating or easy-to-service models for applications with limited access (aerospace) or strict hygiene requirements (medical).

Conclusion: Planetary Roller Screws as a Catalyst for Innovation

Planetary roller screws are more than just motion components—they enable industries to push the boundaries of precision, load capacity, and reliability. From life-saving medical devices to high-efficiency EVs, their ability to solve complex motion challenges makes them a cornerstone of modern engineering. As industries continue to demand higher performance and stricter compliance, planetary roller screws will remain the go-to solution for applications where standard screws cannot keep up. By understanding their capabilities and matching them to specific workflow needs, engineers can design systems that deliver consistent, high-quality results—now and in the future.

Need help selecting the right planetary roller screw for your application? Share your load, precision, and environmental requirements, and our experts will provide tailored recommendations.

Table of Contents

- Why Planetary Roller Screws Outperform Traditional Alternatives in Specialized Applications

-

Key Applications of Planetary Roller Screws Across Industries

- 1. Aerospace & Defense: Reliability in Extreme Conditions

- 2. Heavy Machinery & Industrial Automation: Handling High Loads with Precision

- 3. Medical Devices: Precision & Sterility for Life-Saving Equipment

- 4. Semiconductor & Electronics: Micro-Precision for High-Tech Manufacturing

- 5. Automotive & New Energy: Driving Efficiency in EVs and Heavy-Duty Vehicles

- Critical Considerations for Selecting Planetary Roller Screws for Specific Applications

- Conclusion: Planetary Roller Screws as a Catalyst for Innovation

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ