In the realm of high-load, high-precision linear motion control, planetary roller screws stand as the pinnacle of transmission technology. Bridging the gap between the load capacity of hydraulic systems and the precision of ball screws, these robust components deliver unmatched performance in demanding industrial scenarios. From heavy machinery to aerospace actuation, planetary roller screws redefine reliability, accuracy, and durability—making them indispensable for engineers designing equipment that pushes the boundaries of performance. This blog explores the technology, advantages, applications, and selection criteria of planetary roller screws.

1. How Planetary Roller Screws Work: Engineered for Extreme Performance

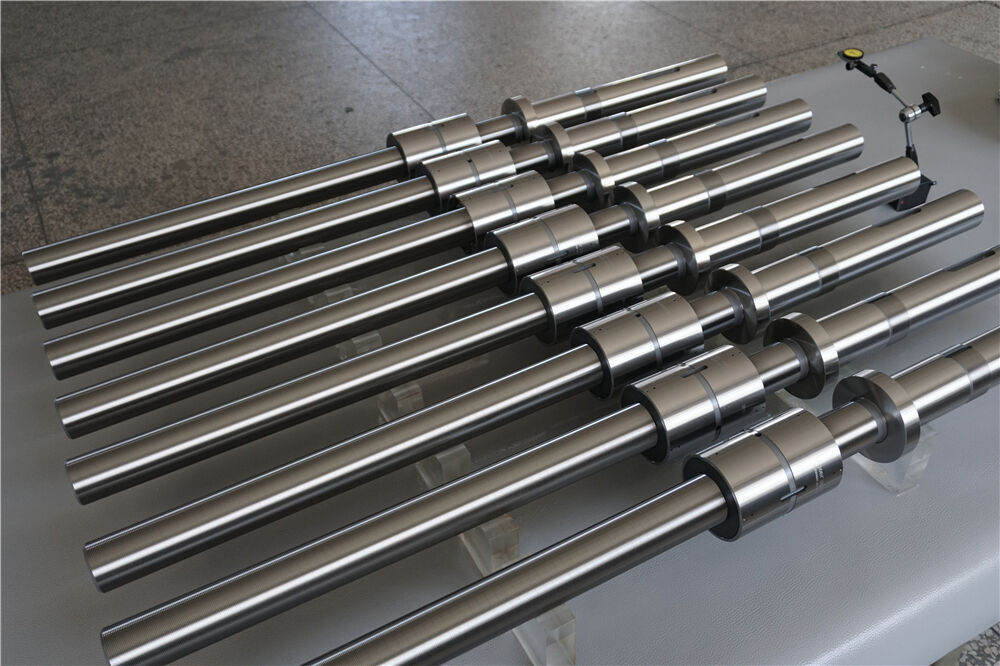

Planetary roller screws share a similar core design to planetary screws but incorporate cylindrical rollers instead of ball bearings or satellite screws, optimizing them for heavy loads. The structure consists of a central screw shaft with a precision thread, multiple cylindrical rollers (arranged circumferentially around the shaft), a roller cage to maintain spacing, and a nut assembly that houses the rollers. As the screw rotates, the rollers engage with both the screw’s thread and the nut’s internal thread, converting rotational motion into smooth linear motion via rolling contact.

The key distinction lies in the contact area: unlike ball screws (point contact) or lead screws (sliding contact), planetary roller screws feature line contact between rollers and threads. This design distributes load across a larger surface area, enabling them to handle significantly higher axial loads while maintaining micron-level precision—a critical advantage for heavy-duty applications.

2. Core Advantages of Planetary Roller Screws Over Competing Technologies

Planetary roller screws outperform traditional transmission components in scenarios where load capacity, precision, and durability are non-negotiable. Their key advantages include:

-

Exceptional Load-Bearing Capacity: Line contact design allows planetary roller screws to handle 3-5 times the axial load of ball screws of the same size, and far exceed lead screws. They excel in static and dynamic load scenarios, making them ideal for hydraulic cylinder replacements and heavy machinery.

-

Micron-Level Precision with Zero Backlash: Precision-ground threads and preloaded roller assemblies eliminate backlash, delivering positioning accuracy of ±0.001mm to ±0.005mm. This precision remains consistent even under extreme loads, outperforming ball screws that may degrade over time.

-

Superior Durability & Long Service Life: Even load distribution minimizes wear on individual components, extending service life to 2-4 times that of ball screws. The robust design resists shock loads and vibrations, ensuring reliable operation in harsh industrial environments.

-

High Rigidity & Stability: The line contact and rigid roller-screw engagement provide exceptional structural rigidity, preventing deflection under heavy loads. This stability is critical for applications like machine tool actuation and aerospace components.

-

Energy Efficiency vs. Hydraulics: As an electromechanical alternative to hydraulic systems, planetary roller screws reduce energy consumption, eliminate fluid leakage risks, and require less maintenance—while matching or exceeding hydraulic load capacity.

3. Key Applications of Planetary Roller Screws Across Industries

Planetary roller screws are engineered for the most demanding applications, where failure is not an option. They are widely adopted in high-end manufacturing, aerospace, and heavy industry:

Aerospace & Defense

In aircraft landing gear actuation, flight control systems, and missile guidance mechanisms, planetary roller screws deliver reliable linear motion under extreme loads, temperature fluctuations, and vibration. Their compact design and high power density meet the strict weight and performance requirements of aerospace applications, replacing bulky hydraulic systems with more efficient electromechanical solutions.

Heavy Machinery & Industrial Automation

In injection molding machines, press brakes, and forging equipment, planetary roller screws handle the massive clamping forces and precise actuation needed for high-volume production. They also excel in robotic arms for heavy payloads (500kg+), ensuring consistent positioning and durability in 24/7 operation.

Machine Tools

CNC machining centers, grinding machines, and milling equipment rely on planetary roller screws for their high rigidity and precision. They enable fast feed rates (up to 5m/s) while maintaining micron-level accuracy, improving machining quality and efficiency—critical for aerospace and automotive component manufacturing.

Energy & Infrastructure

Wind turbine pitch control systems, solar panel trackers, and dam gate actuators use planetary roller screws to handle heavy loads and harsh outdoor conditions. Their durability and low maintenance needs reduce downtime in critical energy infrastructure, ensuring consistent performance in extreme temperatures and weather.

4. Critical Selection Criteria for Planetary Roller Screws

Choosing the right planetary roller screw requires careful alignment with application-specific demands. Key factors to consider include:

-

Load Requirements: Calculate axial, radial, and shock loads to select a screw with the appropriate dynamic and static load ratings. Consider peak loads during start-stop cycles and long-term operational loads.

-

Precision & Backlash: Select an accuracy grade (e.g., ultra-precision, high-precision) based on positioning needs. Preloaded designs are essential for zero-backlash applications like aerospace and machine tools.

-

Environmental Conditions: Choose materials (carbon steel, alloy steel, or stainless steel) and protective coatings (nitride, chrome) to withstand temperature extremes, moisture, dust, or corrosive substances. IP-rated sealing systems enhance durability in harsh environments.

-

Speed & Stroke: Ensure the screw’s maximum rotational speed and stroke length align with application requirements. High-speed applications may require specialized lubrication and cooling systems.

-

Mounting & Integration: Evaluate mounting configurations (fixed-fixed, fixed-floating) and compatibility with existing equipment. Compact designs are ideal for space-constrained applications like robotic arms.

5. Conclusion: Planetary Roller Screws for Extreme Precision & Loads

As industrial demands for higher loads, precision, and efficiency continue to grow, planetary roller screws have become the gold standard for heavy-duty linear motion control. Their unique design combines the best of electromechanical precision and hydraulic load capacity, enabling engineers to develop more reliable, efficient, and compact equipment.

Whether you’re designing a heavy-duty press, aerospace actuator, or high-precision machine tool, our team of experts can help you select or customize planetary roller screws to meet your exact requirements. We offer a full range of standard and custom solutions, engineered with strict quality control to deliver consistent performance in the most demanding environments. Contact us today to explore how planetary roller screws can elevate your motion control systems.

Table of Contents

- 1. How Planetary Roller Screws Work: Engineered for Extreme Performance

- 2. Core Advantages of Planetary Roller Screws Over Competing Technologies

- 3. Key Applications of Planetary Roller Screws Across Industries

- 4. Critical Selection Criteria for Planetary Roller Screws

- 5. Conclusion: Planetary Roller Screws for Extreme Precision & Loads

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ