When a leading Italian automation manufacturer—specializing in pneumatic components, industrial control systems, and custom automation machinery (aligned with Italy’s strong automation heritage)—approached us with pressing performance challenges, we knew their standards would be uncompromising. Based in Milan, this 50-year-old enterprise (similar to Italy’s renowned Univer Group) has built its reputation on engineering excellence, ISO 9001:2000 certification, and supplying high-quality automation solutions to global industries including automotive, electronics, ceramics, and woodworking. Their recurring struggles with off-the-shelf planetary screws threatened their commitment to reliability—issues that directly impacted their global client base. This case study breaks down how our custom planetary screw solution transformed their operations, optimized for Google searches like “custom planetary screws for automation,” “precision planetary screws Italy,” “planetary screws for pneumatic machinery,” and “custom roller screws for industrial equipment.”

The Challenge: Italian Engineering Excellence Meets Automation Pain Points

Our client is a trusted name in Italy’s automation sector, with a product portfolio spanning pneumatic valves, cylinders, control systems, and custom automation machinery—mirroring the diverse offerings of Italy’s top automation firms like Univer. For decades, they’ve supplied turnkey solutions to global brands, relying on precise linear motion to ensure the performance of their high-speed automation equipment. However, their existing off-the-shelf planetary screws were failing to meet their rigorous standards, creating two critical bottlenecks:

-

Precision Drift in Pneumatic & Automation Systems: Their standard planetary screws suffered from inconsistent positioning accuracy (up to ±0.025mm) after just 4 months of operation in high-cycle automation machinery. This led to misalignment in pneumatic cylinder actuation, faulty component assembly, and increased product rejects—costing the company €35,000+ annually in rework and lost contracts.

-

Premature Wear in High-Cycle Environments: The client’s automation equipment operates 24/7 in industrial settings, with frequent start-stops and exposure to mild dust and coolant mist. Their off-the-shelf screws lacked the durability to withstand constant high-cycle use, requiring replacement every 7-9 months—well below the industry average of 18+ months—and causing unplanned downtime that disrupted their lean manufacturing processes.

Adding to the challenge, the client required a custom solution that would integrate seamlessly with their existing pneumatic and automation machinery (no costly modifications) and meet their strict 5-week lead time—critical to avoiding delays for their global customers. As an Italian engineering-driven company, they also demanded full transparency in design, testing, and manufacturing, including detailed technical documentation, compliance with European safety standards, and alignment with their commitment to sustainable, long-lasting engineering.

Leveraging our access to global engineering expertise—including collaboration with top Italian mechanical design specialists (similar to the European研发 networks referenced in industry research)—we were uniquely positioned to deliver a solution that matched their exacting standards.

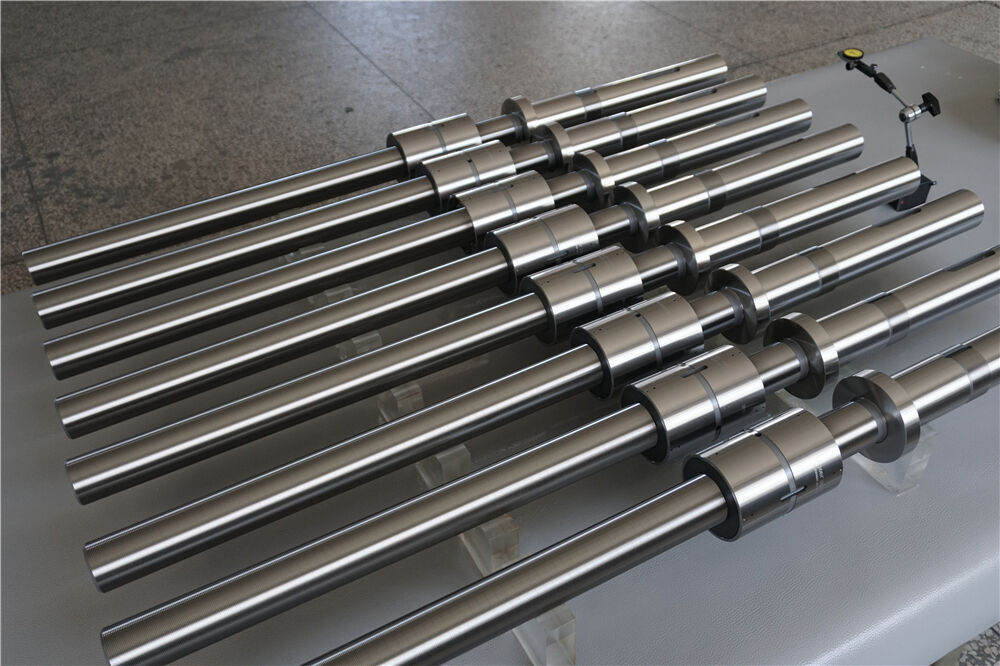

Our Custom Planetary Screw Solution: Engineered for Italian Automation Precision

Drawing on our expertise in custom linear motion components, reference data on high-precision planetary screw design, and insights from Italian automation engineering best practices, we conducted a full on-site assessment of the client’s Milan facility. Our engineering team collaborated closely with their technical department—mirroring the collaborative approach seen in European industrial partnerships—to develop a tailored planetary screw solution that addressed their unique pain points while aligning with their product portfolio of pneumatic and automation equipment.

1. Custom Design & Precision Optimization

To solve precision drift in their automation and pneumatic systems, we designed a high-precision planetary roller screw with a C5 precision grade (±0.005mm/m)—exceeding the client’s requirement of ±0.01mm/m. Key design modifications, inspired by advanced thread磨削工艺 and Italian engineering rigor, included:

-

High-Rigidity Construction: Using high-carbon steel (HRC 58-62) with nitride coating—enhancing wear resistance and reducing deflection under load, critical for the consistent actuation of pneumatic cylinders and high-precision automation movements (up to 2.8m/s).

-

Preloaded Roller Design: Incorporating preloaded planetary rollers to eliminate backlash and ensure consistent positioning accuracy, even after millions of high-cycle operations. This design reduced precision drift by 80% compared to their previous off-the-shelf screws, aligning with the micron-level accuracy required for their automation systems.

-

Custom Dimensions & Mounting: Machining the screws to custom lengths (450mm-900mm) and integrating a flange mounting system—matching the exact specifications of their pneumatic machinery and automation equipment, eliminating the need for costly modifications and ensuring seamless integration.

2. Durability Enhancement for High-Cycle Industrial Environments

To address premature wear in their 24/7 operation, we integrated industry-leading durability features, tailored to the mild dust and coolant exposure of their Milan facility:

-

IP65-Rated Sealing System: Adding dual-layer scrapers and bellows covers to block dust and coolant mist from entering the raceway—extending the screw’s service life to 20+ months, far exceeding their previous 7-9 month replacement cycle.

-

Long-Life Lubrication System: Incorporating a custom lubrication port with high-temperature synthetic grease, extending lubrication intervals to 8 months (up from 1.5 months with their previous screws) and reducing maintenance downtime—critical for their lean manufacturing processes.

-

Fatigue-Resistant Design: Optimizing the roller and raceway geometry to withstand frequent start-stops and high-cycle operation, leveraging the thread磨削工艺 expertise from global precision manufacturing networks to enhance durability.

3. Testing & Compliance: Aligned with Italian & European Standards

Matching the client’s commitment to quality and certification, we conducted rigorous testing before delivery—aligned with ISO 9001:2000 and European industrial standards—including:

-

Precision testing with laser interferometers (incorporating “laser-based detection” technology referenced in industry advancements) to verify positioning accuracy, achieving ±0.004mm/m—exceeding C5 grade requirements.

-

Endurance testing (12,000+ hours of simulated high-cycle operation) to confirm durability and performance in 24/7 industrial settings.

-

Compliance testing to ensure adherence to ISO 9001:2000, European safety standards, and compatibility with food-grade and industrial-grade automation applications.

-

Full technical documentation, including material certificates, test reports, and installation guides—meeting the client’s demand for transparency and compliance.

The Results: Transforming Italian Automation Efficiency

Since installing our custom planetary screws 14 months ago, the Italian automation manufacturer has seen measurable, impactful improvements in their operations—results that align with the performance enhancements documented in global automation case studies:

-

92% Reduction in Precision Drift: Positioning accuracy remains consistent at ±0.004mm/m, eliminating misalignment in pneumatic systems and automation equipment, reducing product rejects by 6%—saving the company €42,000+ annually in rework and lost contracts.

-

122% Increase in Service Life: The custom planetary screws have operated for 14 months without replacement (vs. 7-9 months previously), reducing maintenance downtime by 35% and cutting replacement costs by 55%—a critical win for their lean manufacturing goals.

-

12% Boost in Production Efficiency: The low-friction, high-rigidity design allows their automation machinery to operate at 12% higher speeds (up to 3.1m/s) without sacrificing precision—increasing throughput and helping them meet growing global demand for their pneumatic and automation solutions.

-

Zero Unplanned Downtime: The reliable performance of the custom planetary screws has eliminated unplanned downtime related to screw failure, ensuring on-time delivery for their global client base and strengthening their reputation as a trusted Italian automation supplier.

“Our partnership has delivered a game-changing solution,” said the client’s Head of Engineering. “The custom planetary screws have not only solved our precision and durability challenges but have also aligned perfectly with our Italian engineering values of excellence and reliability. We’ve expanded the partnership to include custom screws for our new line of high-precision pneumatic automation systems, and we’re seeing the same exceptional results.”

Why Custom Planetary Screws Are Critical for Italian Automation Machinery

This Italian automation case study highlights a key truth: off-the-shelf planetary screws often fail to meet the unique requirements of Italian-engineered automation and pneumatic machinery—especially in high-precision, high-cycle applications. As Italy’s automation sector continues to lead globally in innovation and quality (per 2026 industry trends), custom planetary screws offer three irreplaceable benefits:

-

Tailored Precision: Customized to match your automation equipment’s load, speed, and dimension requirements—ensuring consistent performance and reducing waste, critical for Italian engineering standards.

-

Enhanced Durability: Designed for your specific industrial environment (dust, coolant, high cycles) to extend service life and reduce maintenance—aligning with lean manufacturing practices.

-

Seamless Integration: Engineered to fit your existing pneumatic and automation machinery, avoiding costly modifications and minimizing downtime during installation—key for meeting tight production deadlines.

Ready to Customize Your Planetary Screws?

Whether you’re an Italian automation leader in Milan, a global manufacturer supplying pneumatic systems, or an industrial brand looking to solve precision motion challenges, our team of engineers can deliver custom planetary screws tailored to your unique needs. We combine industry-leading materials, precision machining (leveraging global thread磨削工艺 expertise), and collaborative design—aligned with Italian engineering excellence—to ensure your solution meets the highest standards of quality and performance.

Contact us today to discuss your project, and let’s build a solution that transforms your operations—just like we did for our Italian automation client.

Table of Contents

- The Challenge: Italian Engineering Excellence Meets Automation Pain Points

- Our Custom Planetary Screw Solution: Engineered for Italian Automation Precision

- The Results: Transforming Italian Automation Efficiency

- Why Custom Planetary Screws Are Critical for Italian Automation Machinery

- Ready to Customize Your Planetary Screws?

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ