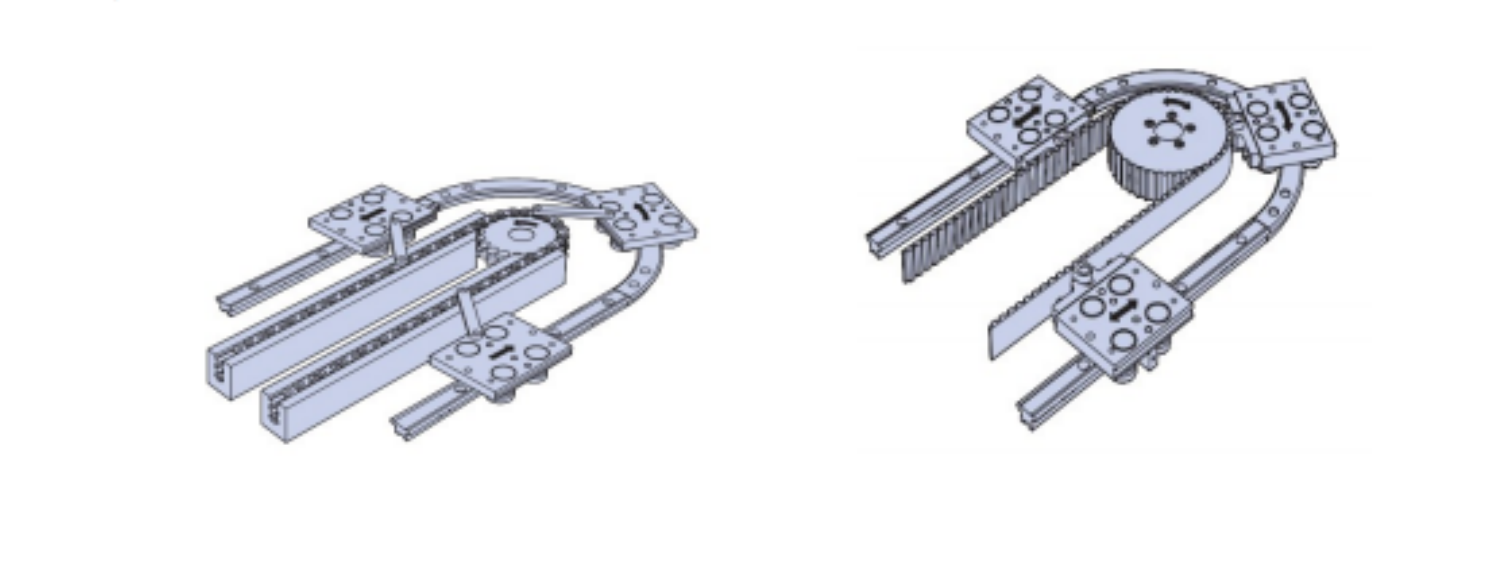

O'rnatish usuli ko'proq fleksibel. Dorixli slayd doira yordamchisi bo'yicha harakatlanadi.

YOSO Doira Yordamchi Seriyasi

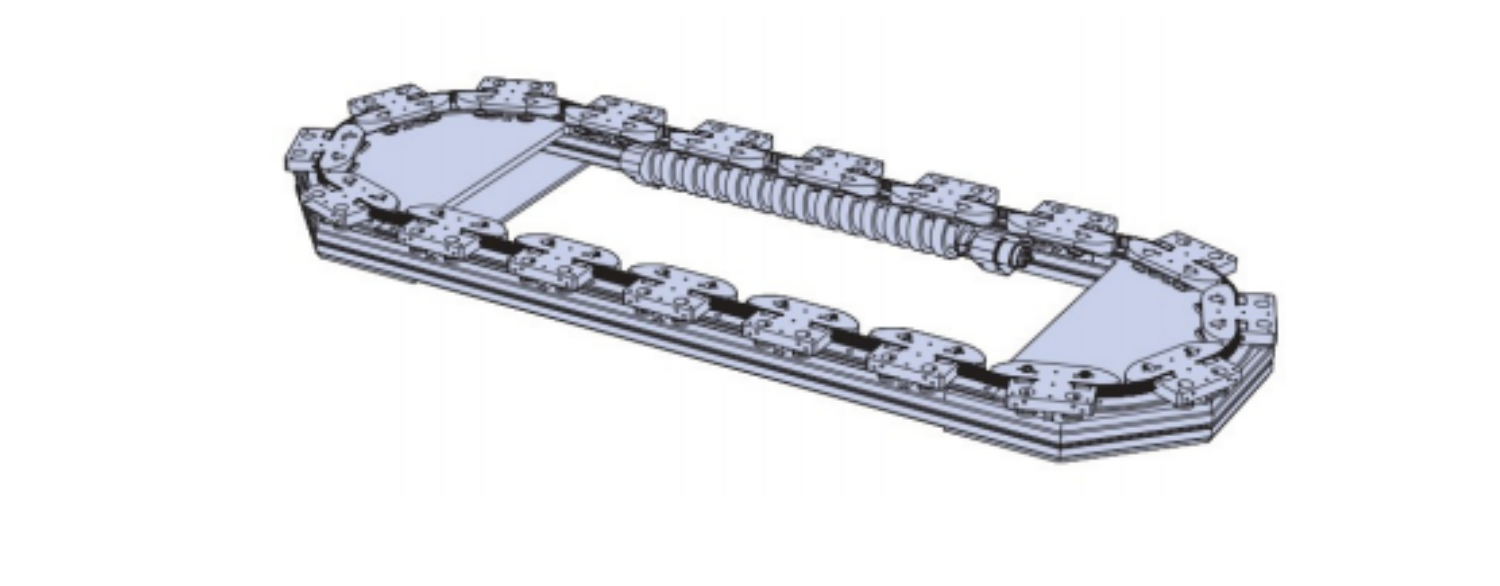

Ark lineyniy rekvod roller turli lineyniy rekvod rels va ball turli lineyniy rekvod relslariga ega. To'g'ri qator rekvod relsi shakllantirish mumkin; Ishlash tizimi bilan bog'langan bo'lsa, u to'g'ri qator montaj chiziqli, qator chiziqli yoki qator montaj chiziqlari va boshqa tsikl chiziqlari shakllantirishi mumkin. Ushbu turdagi rekvod tsikl chizmasi, kengaytirilgan struktura, ushlab turuvchi aniqlik, ko'proq konfiguratsiya tanlovi mavjud; Ko'plab holatlarda bu, klassik yetkazib beradigan chiziqlardan yaxshiroq.

Mumossal asosidagi muassasalar, har doim ishlab chiqarish xarajotlarini pasaytirish uchun yo'llarni izlaydi, avtomatlashtirish yo'nalishi: har bir stantsiyani imkoniyatiga qarama-qarshi yaxshilash, ish materiali orasidagi masofani kamaytirish va joy egasining eng kichik sahmasini minimal holatda saqlash; Buning amalga oshirilishi uchun, ish materialiga aylana harakati qilish kerak, siz aylana chizmasidan foydalanishingiz kerak. Aylana chizma ikki turdagi, klassik non-rekvod va aniqlik rekvodi, quyidagicha tasniflanadi:

Klassik kengash turli

Tallyq chiziq, oddiy tuzilma bilan yetishadi, ikki bo'ylangich oralig'ida belgilangan masofaga bo'lgan keng tallyq pastki qismi ikkala tomonidan ajratilgan, bo'ylangich aylantirilishi, tallyq pastki qismi harakatlanishi, jismoniy birikmalar pastki qismida harakatlanadi. Bo'ylangichli tallyq chiziq va tallyqli tallyq chiziq, mazmun jihatdan o'xshash, faqat tallyq o'rniga ko'p sonli yoyuq bo'lmish.

Yoqilg‘i yo‘q qirrali chiziqda, ish materiali shlayka yoki rollarga sabblab turadi, bu engli emas, og‘irlikning attritson kuchi orqali hosil bo‘ladi va ish materialining chap va o‘ng, oldin va orqa va yuqori harakatini yaxshi cheklab bo‘lmaydi. Ish materialining tashlab ketmasligi uchun shlaykaning yoki dumaning ikki tomoniga barier qo‘shish kerak bo‘ladi. Chunki ish materiali shlaykaga yoki rollarga sabblamaganligi sababli, ish materiali bir necha marta siljishi mumkin; agar ish materialining ko‘rinishi ko‘p xil bo‘lsa, konveyor chiziqlari qismi bilan birga bog‘lanishi mumkin. Og‘irlik attritsonidan foydalanib ish materialini konveyor chiziqlarida sabblash, yaxshi pozitsiya aniqligisini ta’minlashni ta’minlay olmaydi, unda konveyor chiziqlarini vertikalga qo‘yishni ta’minlay olmaydi. Sabblangan

ish materiali engli emas, bu esa konveyor chiziqlari tezligini cheklaydi.

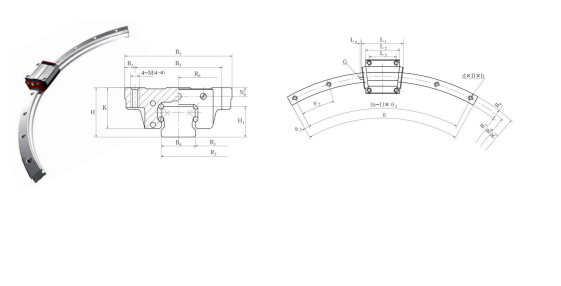

Islem qismi slayd o'simligida sabitlanadi, slayd o'simligi rollyar orqali yordamchi yo'l bo'ylab siljishi mumkin. Yordamchi yo'l slayd o'simligining ozodlik darajasini cheklaydi, faqat bitta yo'nalishdagi harakatga ruxsat beradi. Shuning uchun, ring kanal turi bilan yordamchi yo'l, ko'p tezlik bilan, ko'p belgilash aniqlikiga ega. Ushbu ikki xususiyat to'g'ri automatiklashtirish talablariga javob beradi.

Jami sakkizda, agar siz kichik joyda bo'lishi kerak bo'lsa, to'g'ri automatiklashtirishni amalga oshiring: ish materiali stansialar orasida tez harakat qiladi; Harakat tugagandan so'ng, ish materiali yaxshi belgilash aniqligiga ega; Harakat tugagandan so'ng, ish materialiga qo'shimcha kuch amal qilinadi va uzgaruvchan ishlab chiqarish yoki uzgaruvchan qo'llash amalga oshiriladi; Keyin siz aksariyat ring yordamchi yo'lni tanlashingiz mumkin ring kanalingizning dizayni asos sifatida.

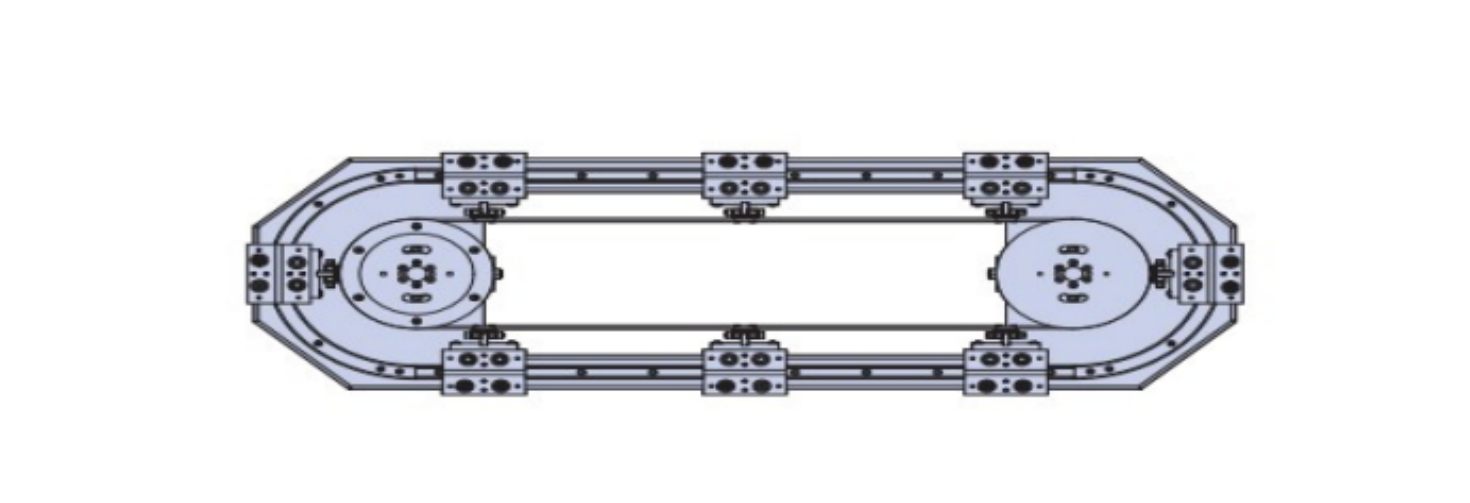

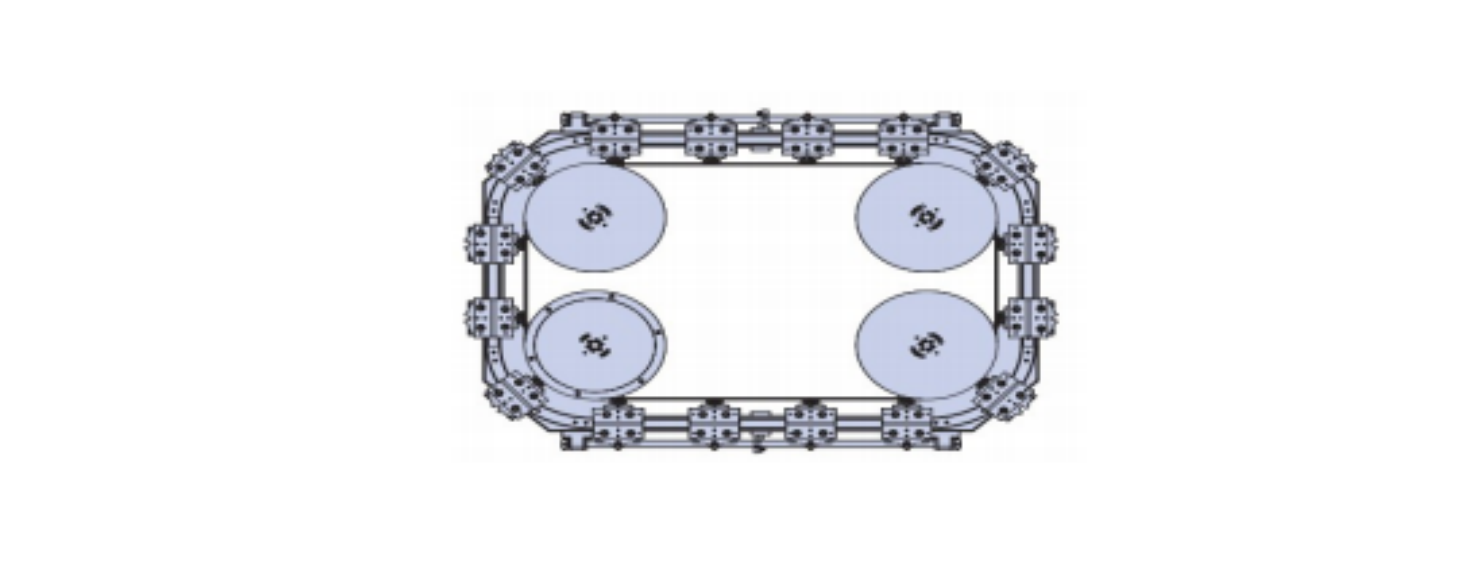

Ring yordamchi yo'lni ring kanal sifatida foydalanish uchun ikkita asosiy usul mavjud: maraton shakli va kvadrat:

Arkliy qo'llanma, harakat tizimi bilan bog'langan bo'lib, doira ko'rinishidagi to'plash chiziqli asosini shakllantiradi. Hozirda uchta asosiy harakat rejimi mavjud: zanjirli, sinxron sho'lcha va vitka turida:

| Model | Qo'llanma o'lchami | Slayder o'lchami | Maslo qutisi o'lchami | ||||||||||

| H | B1 | B2 | B3 | K | L1 | L2 | L3 | M | f | L4 | G | N | |

| YCR16/168AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | Ms | 4.5 | 7 | M4 | 4 |

| YCR16/228AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | Ms | 4.5 | 7 | M4 | 4 |

| YCR16/300AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | Ms | 4.5 | 7 | M4 | 4 |

| YCR16/390AA(AB) | 24 | 47 | 4.5 | 38 | 19.4 | 58 | 40.5 | 30 | Ms | 4.5 | 7 | M4 | 4 |

| YCR25/230AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/400AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | MB | 7 | 11 | M6 | 6 |

| YCR25/500AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/750AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR25/1000AA(AB) | 36 | 70 | 6.5 | 57 | 28.8 | 79.5 | 59 | 45 | M8 | 7 | 11 | M6 | 6 |

| YCR35/600AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/800AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/1000AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| YCR35/1300AA(AB) | 48 | 100 | 9 | 82 | 38 | 111 | 81 | 58 | M10 | 11 | 11 | M6 | 8 |

| Rejalarni qo'llab-quvvatlash | Eng kichik yakuniy burchak | Nominal dinamik yuk | Статик ёрдамли куч | Статик ёрдамли момент | Слайд вогт кг | Ралл веси Кг/м | Model | |||||||||

| B4 | H1 | даDух | θ | R θ | R1 | R2 | θm | θ 1 | C (MN) | (KN) | MA (N-m) | Mb (N·m) | Mc (N-m) | |||

| 16 | 15 | 4.5x7.5x5.3 | 15° | 168 | 160 | 176 | 160° | 3° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | YCR16/16BAA(AB) |

| 16 | 15 | 45x7.5x5.3 | 15° | 228 | 220 | 236 | 160° | 3° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 15 | YCR:16/228AA(AB) |

| 16 | 15 | 45x7.5x5.3 | 15° | 300 | 292 | 30G | 75° | 2° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | VCR16/30GAA(AB) |

| 16 | 15 | 4.5x7.5x5.3 | 15 | 390 | 382 | 398 | 65° | 2° | 5.67 | 6.35 | 51.8 | 51.8 | 829 | 0.2 | 1.5 | YCR 16/39GAA(AB) |

| 23 | 22 | 7x11x9 | 15° | 230 | 218.5 | 241.5 | 160° | 3° | 16.8 | 21.5 | 142.2 | 142.2 | 233.5 | 0.59 | 3.3 | YCR25/23GAA(AB) |

| 23 | 22 | 7x11x9 | 10° | 400 | 388.5 | 411.5 | 60° | 2° | 16.8 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 3.3 | YCR25/40GAA(AB) |

| 23 | 22 | 7x11x | 7° | 500 | 488.5 | 511.5 | 60° | 2° | 168 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 3.3 | YCR25/SOGAA(AB) |

| 23 | 22 | 7x11x9 | 5* | 750 | 738.5 | 751.5 | 35° | 2° | 16.8 | 21.5 | 142.2 | 142.2 | 233.5 | 0.99 | 3.3 | YCR25/75GAA(AB) |

| 23 | 22 | 7x11x | 4° | 10:00 | 988.5 | 1011.5 | 28° | 2° | 16.8 | 21.5 | 142.2 | 1422 | 233.5 | 0.99 | 33 | YCR25/1000A.A(AB) |

| 34 | 29 | 9x14x12 | 9" | 600 | 583 | 617 | 60° | 2° | 3497 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | YCR 3S/SOGAA(AB) |

| 34 | 29 | 9x14x12 | 5.5 | 800 | 783 | 817 | 35° | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | VCR 35/BOGAA(AB) |

| 34 | 29 | 9x14x12 | 5° | 1000 | 983 | 1017 | 28* | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 65 | YCR3S/1000AA(AB) |

| 34 | 29 | 9x14x12 | 3.5 | 1300 | 1283 | 1317 | 22° | 2* | 34.97 | 58.53 | 610 | 610 | 1030 | 1.4 | 6.5 | YCR35/1300AA(AB) |

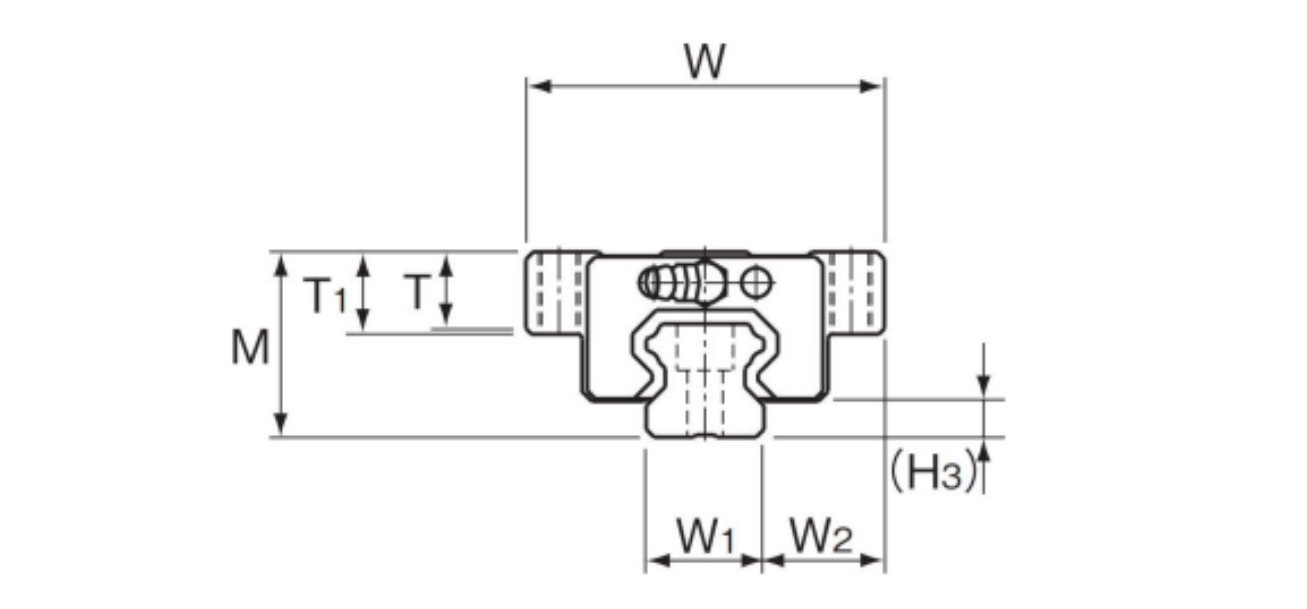

| Model raqami | Tashqi o'lchamlar | LM blok o'lchamlari | H3 | ||||||||||

| Balandligi M | Kengligi W | Uzunligi L | B | C | S | L1 | T | T1 | N | E | Tuyak mukavvati | ||

| YCR15A+60/150R | 24 | 47 | 54.5 | 38 | 24 | M5 | 38.8 | 10.3 | 11 | 45 | 5.5 | PB1021B | 4.8 |

| YCR15A+60/300R | 55.5 | 28 | |||||||||||

| YCR15A+60/400R | 55.8 | 28 | |||||||||||

| YCR25A+60/500R | 36 | 70 | 81.6 | 57 | 45 | MB | 59.5 | 149 | 16 | 6 | 12 | B-M6F | 7 |

| YCR25A+60/750R | 82.3 | ||||||||||||

| YCR25A+60/1000R | 82.5 | ||||||||||||

| YCR35A+60/600R | 48 | 100 | 107.2 | 82 | 58 | M10 | 80.4 | 19.9 | 21 | 8 | 12 | B-M6F | 8.5 |

| YCR35A+60/800R | 107.5 | ||||||||||||

| YCR35A+60/1000R | 108.2 | ||||||||||||

| YCR35A+60/1300R | 108.5 | ||||||||||||

| YCR45A+60/800R | 60 | 120 | 136.7 | 100 | 70 | M12 | 98 | 239 | 25 | 10 | 16 | B-PT1/8 | 11.5 |

| YCR45A+60/1000R | 137.3 | ||||||||||||

| YCR45A+60/1200R | 137.3 | ||||||||||||

| YCR45A+60/1600R | 138 | ||||||||||||

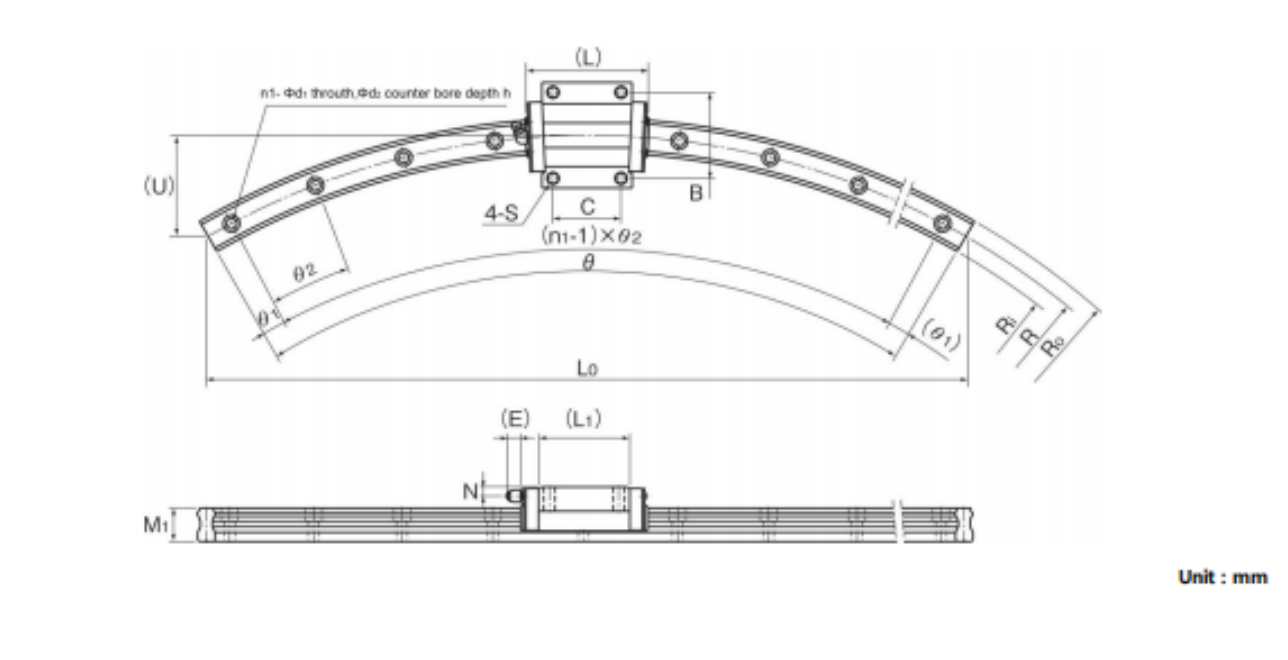

| LM doragi o'lchamlari | Asosiy yuk reytingi | Statik ruxsat etilgan moment kN·m | Massa | ||||||||||||||||||

| R | Ro | Ri | LO | U | Kenglik W1 | W2 | Balandlik M1 | d1xd2xh | m1 | θ° | θ ° | θ 2 | kN | CO kN | MA | MB 0 | MC 6 | LM Blok kg | LM Ral kg/m | ||

| 1 Blok | Dvoynye Bloki | 1 Blok | Dvoynye Bloki | 1 Blok | |||||||||||||||||

| 150 | 157.5 | 142.5 | 150 | 20.1 | 15 | 16 | 15 | 4.5x7.5x5.3 | 3 | 7 | 23 | 6.66 | 10.8 | 0.0805 | 0.457 | 0.080 5 | 0.457 | 0.084 4 | 0.2 | 1.5 | |

| 300 | 307.5 | 2925 | 300 | 40 | 5 | 6 | 12 | 8.33 | 13.5 | ||||||||||||

| 400 | 407.5 | 392.5 | 400 | 54 | 7 | 3 | 9 | 8.33 | 13.5 | ||||||||||||

| 500 | 511.5 | 488.5 | 500 | 67 | 23 | 23.5 | 22 | 7x11x9 | 9 | 2 | 7 | 19.9 | 344 | 0.307 | 1.71 0 | .307 | 1.71 | 0.344 | 0.59 | 3.3 | |

| 750 | 761.5 | 738.5 | 750 | 100 | 12 | 2.5 | 5 | ||||||||||||||

| 1000 | 1011.5 | 988.5 | 1000 | 134 | 15 | 2 | 4 | ||||||||||||||

| 600 | 617 | 583 | 600 | 80 | 34 | 33 | 29 | 9x14x12 | 7 | 3 | 9 | 37.3 | 61.1 | 0.782 | 3.93 0 | .782 | 3.93 | 0.905 | 1.6 | 6.6 | |

| 800 | 817 | 793 | 800 | 107 | 11 | 2.5 | 5.5 | ||||||||||||||

| 1000 | 1017 | 983 | 1000 | 134 | 12 | 2.5 | 5 | ||||||||||||||

| 1300 | 1317 | 1283 | 1300 | 174 | 17 | 2 | 3.5 | ||||||||||||||

| 800 | 822.5 | 777.5 | 800 | 107 | 45 | 37.5 | 38 | 14x20x17 | 8 | 60 | 2 | 8 | 60 | 95.6 | 1.42 | 7.92 | 1.42 | 7.92 | 1.83 | 2.8 | 11.0 |

| 1000 | 1022.5 | 977.5 | 1000 | 134 | 10 | 3 | 6 | ||||||||||||||

| 12.00 | 1222.5 | 1177.5 | 1200 | 161 | 12 | 2.5 | 5 | ||||||||||||||

| 1600 | 1622.5 | 1577.5 | 1600 | 214 | 15 | 2 | 4 | ||||||||||||||

Hamma huquqlar saqlangan © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd