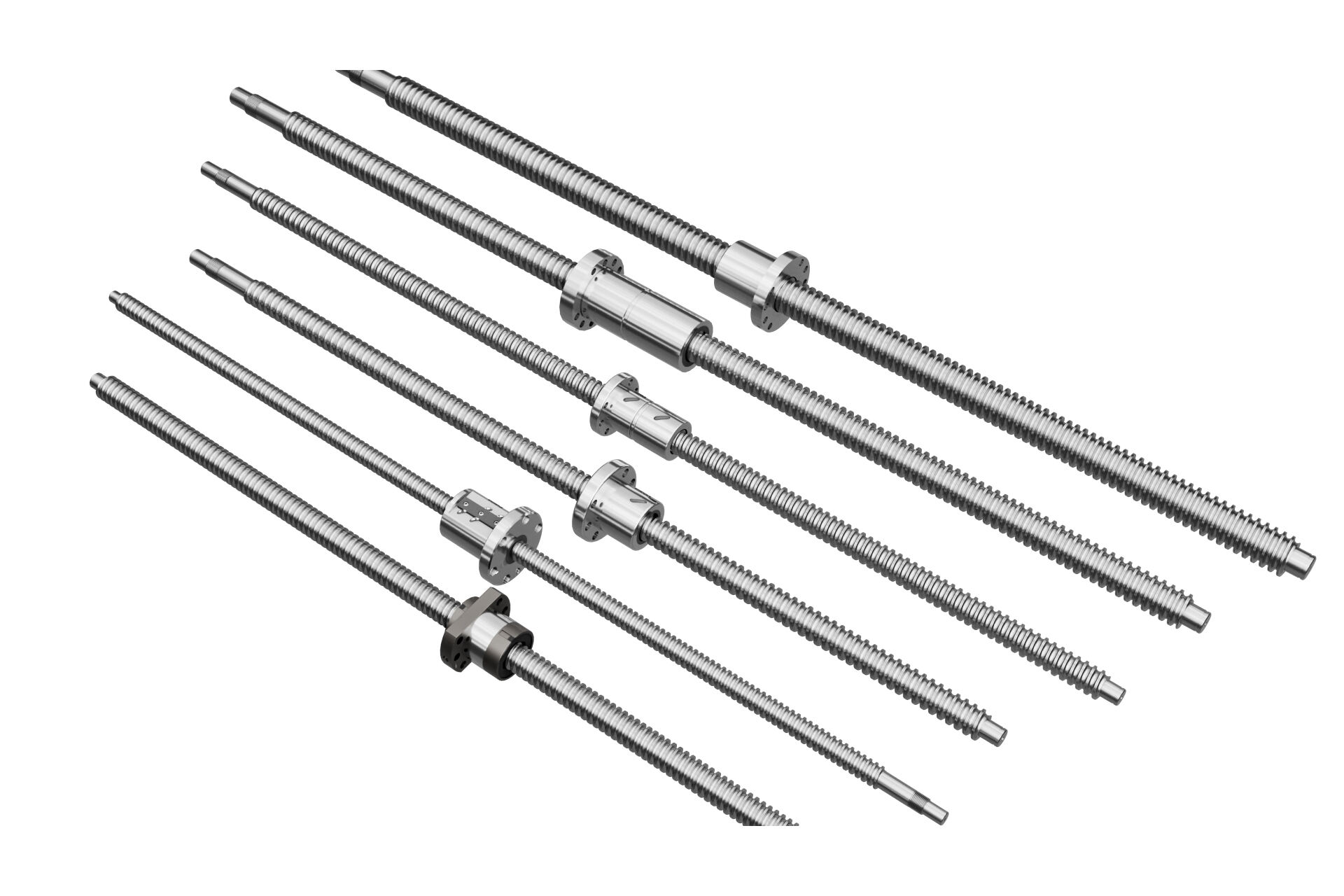

Endüstriyel otomasyon, CNC tezgâhları ve hassas ekipmanlarda temel iletim elemanı olarak bilyalı vidalar; yüksek verimlilikleri, yüksek doğrulukları ve uzun ömürleriyle bilinir. Dönme hareketi ile doğrusal hareket arasındaki dönüşümü minimum enerji kaybıyla gerçekleştirerek mekanik sistemlerin hassasiyeti ve kararlılığı için kilit bir güvence haline gelir. Bu makale, bilyalı vidaların tanımı, yapısal bileşimi, bilimsel sınıflandırma, hassasiyet derecelendirmesi, teknik özellikleri ve pratik seçim açısından kapsamlı bir şekilde yorumlanmasını sağlayarak bu kritik bileşenin teknik özünü derinlemesine kavramanıza yardımcı olur.

1. Doğru Tanım ve Temel Çalışma Prensibi Balta vitleri

Bilyalı vida (bilyalı rulman vidası olarak da bilinir), vida mili ile somun arasındaki hassas çelik bilyeleri yuvarlanan elemanlar olarak kullanarak vidanın döner hareketini somunun doğrusal hareketine (veya tam tersi) dönüştüren mekanik bir iletim cihazıdır. Kayma sürtünmesine dayanan geleneksel trapez vidalara kıyasla, çelik bilyeler ile vida/somun oluğu arasındaki yuvarlanma sürtünmesi sürtünme katsayısını büyük ölçüde azaltır ve böylece daha yüksek iletim verimliliği ve konumlandırma doğruluğu sağlar.

Temel çalışma prensibi: Vida mili, bir güç kaynağından (örneğin servo motor) gelen tahrikle döndüğünde, somun yuvasındaki bilyeler vidanın spiral oluğunda yuvarlanır. Geri dönüş cihazı (bilye sirkülasyon sistemi) tarafından sınırlandırılmış olarak, bilyeler vida ile somun arasında sürekli dönerler ve böylece birbirleriyle çarpışmayı ve aşınmayı önlerler. Bilyeler yuvarlanırken aynı zamanda somunu vida ekseni boyunca doğrusal hareket yapmaya zorlar; bunun tersine, somun doğrusal bir kuvvete maruz kaldığında vida milini döndürebilir ve böylece dönme ile doğrusal hareket arasında çift yönlü dönüşüm sağlanır.

2. Temel Yapısal Bileşenler Balta vitleri

Tam bir bilyalı vida takımı, ürünün iletim performansını ve kullanım ömrünü doğrudan etkileyen beş ana bileşenden oluşur. Yapı tasarımı konusundaki uygunluk, yüksek hassasiyet ve yüksek verimlilik sağlamanın temelidir:

-

Viteli çivit : Genellikle yüksek karbonlu krom rulman çeliğinden (SUJ2) veya alaşımlı yapı çeliğinden (SCM440) yapılan ve yüzeyinde spiral oluk işlenerek oluşturulan temel bileşen. Sertleştirme ve temperleme, hassas taşlama ve diğer işlemlerden sonra yüksek sertliğe (HRC58-62) ve yüzey pürüzsüzlüğüne (Ra ≤ 0,2 μm) sahip olur; bu da bilyelerin sorunsuz yuvarlanmasını ve aşınma direncini sağlar.

-

Somun : İç kısımdaki vida ile eşleşen spiral oluklu eşleştirme parçası. Malzemesi vida miliyle aynıdır ve mil ile uyumun tutarlılığını sağlamak için oluk hassas taşlama işleminden geçirilir. Somun, doğrusal hareketli bileşene (örneğin bir tabla gibi) bağlanmak üzere bir montaj arayüzüne de sahiptir.

-

Çelik Bilyeler : Genellikle yüksek hassasiyetli rulman çelik bilyelerinden (G10-G3) yapılan, vida ile somun arasındaki yuvarlanan elemanlar ve ±0,001 mm çap toleransına sahiptir. Çelik bilyelerin boyutu ve sayısı doğrudan bilyalı vidanın taşıma kapasitesini ve rijitliğini belirler.

-

Geri Dönüş Cihazı (Bilye Dolaşım Sistemi) : Çelik bilyelerin sürekli dolaşımını sağlayan ana bileşen olup, dolaşım moduna göre iç dolaşım ve dış dolaşım olarak ayrılabilir. Fonksiyonu, yuvarlanarak somun ucuna ulaşan bilyeleri tekrar oluğun başlangıç ucuna yönlendirerek iletimin sürekliliğini sağlamaktır. Geri dönüş cihazının tasarımı, bilyalı vidanın çalışma pürüzsüzlüğüne ve gürültü seviyesine doğrudan etki eder.

-

Mühürleme Cihazı : Somunun her iki ucuna ve dış çevresine takılarak, toz, metal talaşları, kesme sıvısı ve diğer yabancı maddelerin yuvarlanma yoluna girmesini engellemek ve aynı zamanda yağın sızmasını önlemek için kullanılır. Yaygın conta türleri arasında çalışma ortamına göre seçilen temaslı contalar (örneğin yün contalar, kauçuk contalar) ve temaslı olmayan contalar (örneğin labirent contaları) bulunur.

3. Bilyalı Mili Bilimsel Sınıflandırması

Bilyalı miller, birden fazla profesyonel boyuta göre farklı türler halinde sınıflandırılabilir. Sınıflandırma kriterlerinin belirlenmesi, ürünü uygulama alanıyla doğru şekilde eşleştirmeye yardımcı olur. Sektördeki ana sınıflandırma yöntemleri şunlardır:

3.1 Bilya Dönüş Moduna Göre Sınıflandırma

Bu, en yaygın sınıflandırma yöntemidir ve bilyaların somun içinde dönüş şekline göre yapılır:

-

İç Dönüşlü Bilyalı Mil : Bilyalar somun içinde dolaşır. Geri dönüş sistemi, somunun içine işlenmiş bir geri dönüş kanalıdır (genellikle dairesel yay oluğu veya geçit deliği). Bilyalar, yuvarlanma yolunun ucundan geri dönüş kanalına girer ve başlangıç ucuna geri döner. Avantajları: kompakt yapı, küçük somun hacmi, yüksek çalışma pürüzsüzlüğü, düşük gürültü (genellikle ≤ 60 dB) ve yüksek hızlı çalışmaya uygunluk (maksimum hız 3000 devir/dakika). Dezavantajları: karmaşık işleme teknolojisi ve nispeten yüksek maliyet. CNC tezgahlarında, hassas elektronik ekipmanlarda ve diğer yüksek hassasiyetli uygulamalarda yaygın olarak kullanılır.

-

Dış Dönüşlü Bilyalı Mil : Bilyalar somunun dışında dolaşır. Geri dönüş sistemi, somunun dış yüzeyine monte edilmiş bir çelik boru veya plastik kılavuz oluktur. Bilyalar, somun yuvasından çıkarak geri dönüş borusuna girer ve somunun diğer ucuna geri döner. Avantajları: Basit üretim teknolojisi, düşük maliyet, bakımı kolay ve yük taşıma kapasitesini artırmak için çok devreli olarak tasarlanabilir. Dezavantajları: Somun hacmi büyük, çalışma gürültüsü nispeten yüksek ve maksimum hız sınırlıdır (genellikle ≤ 2000 rpm). Hız ve gürültü açısından düşük gereksinimleri olan genel otomasyon ekipmanları, ağır makinalar ve benzeri uygulamalar için uygundur.

3.2 Vida Oluk Profiline Göre Sınıflandırma

Vidanın ve somunun spiral yuva kesitinin şekil yapısına göre bölünür; bu durum bilya ile yuva arasındaki temas durumunu etkiler:

-

Kavisli Oluklu Bilyalı Vida : Raylı yol kesiti, çelik bilya yarıçapından biraz daha büyük olan (genellikle çelik bilya yarıçapının 1,02-1,05 katı) bir yay şeklindedir. Avantajları: İyi temas stabilitesi, radyal yükleri ve devrilme momentlerini taşıma kabiliyeti güçlü ve yüksek rijitlik. Dezavantajları: Çelik bilya ile raylı yol arasındaki temas alanı küçük olup taşıma kapasitesi nispeten sınırlıdır. Küçük yüklerle yüksek hassasiyetli konumlandırma gerektiren uygulamalara uygundur.

-

Gotik Kemer Oluklu Bilyalı Mil : Raylı yol kesiti Gotik kemer şeklinde olup (zıt yarıçaplı iki yaydan oluşur). Avantajları: Çelik bilya, raylı yolla iki noktada temas eder ve hem eksenel yükleri hem de radyal yükleri taşıyabilir; taşıma kapasitesi yay oluğununkinden 1,5-2 kat daha fazladır. Dezavantajları: Yüksek işleme hassasiyeti gerektirir ve temas hali montaj hatalarına duyarlıdır. Ağır yük ve yüksek rijitlik gerektiren uygulamalar için uygundur, örneğin ağır iş tipi CNC tezgahları ve hidrolik presler.

3.3 Adım Hassasiyetine Göre Sınıflandırma

Adım hatasına göre (gerçek adım ile teorik adım arasındaki sapma) bölünür ve bu vida milinin konumlandırma doğruluğunu yansıtan temel göstergedir. Sınıflandırma standartları uluslararası standartlara (ISO 3408) ve ulusal standartlara (GB/T 17587.1-2017) atıfta bulunur:

-

Hassasiyet Sınıfı C1-C5 (Yüksek Hassasiyet) : Sapma hatası küçüktür (C1 sınıfı sapma hatası ≤ 0,003 mm/300 mm, C5 sınıfı ≤ 0,012 mm/300 mm), yüksek tekrarlı konumlandırma doğruluğuna sahiptir (≤ 0,005 mm). Hassas taşlama ve ince ayarlamanın ardından yarı iletken ambalaj makineleri, optik enstrüman konumlandırma aşamaları ve hassas CNC işleme merkezleri gibi ultra hassasiyetli ekipmanlara uygundur.

-

Hassasiyet Sınıfı C7-C10 (Orta Hassasiyet) : Sapma hatası orta düzeydedir (C7 sınıfı ≤ 0,025 mm/300 mm, C10 sınıfı ≤ 0,050 mm/300 mm), hassasiyet ile maliyet arasında denge sağlar. Endüstriyel otomasyonda en yaygın kullanılan sınıftır ve genel amaçlı CNC tezgahları, lineer modüller, robot kolları ve diğer ekipmanlar için uygundur.

-

Hassasiyet Sınıfı C16 (Genel Hassasiyet) : Sapma hatası nispeten büyüktür (≤ 0,100 mm/300 mm), haddeleme şekillendirme ile işlenir, üretim verimliliği yüksektir ve maliyet düşüktür. Normal taşıyıcılar, otomatik kapı mekanizmaları ve basit kaldırma platformları gibi düşük hassasiyetli aktarma uygulamaları için uygundur.

3.4 Montaj Şekline Göre Sınıflandırma

Vidalı milin iki ucunun sabitlenme şekline göre bölünür ve bu durum bilyalı vida mili rijitliğini ve strokunu etkiler:

-

Sabit-Sabit Tip : Milin her iki ucu da açısal temaslı bilyalı rulmanlarla sabitlenir. Avantajları: En yüksek rijitliğe sahiptir, büyük eksenel yükleri ve devrilme momentlerini taşıyabilir ve kritik hızı yüksektir; uzun stroklu, yüksek hızlı ve yüksek rijitlik gerektiren uygulamalar için uygundur (örneğin büyük boyutlu CNC tezgahları).

-

Sabit-Serbest Tip : Milin bir ucu sabitlenmiş, diğer ucu serbesttir (rulmanla desteklenmez). Avantajları: Kurulumu basittir, çalışma sırasında vidanın termal genleşmesini ve daralmasını telafi edebilir. Dezavantajları: Düşük rijitlik, taşıma kapasitesi sınırlıdır; kısa stroklu, düşük hızlı uygulamalar için uygundur (örneğin küçük elektronik cihazlar).

-

Sabit-Destekli Tip : Vida'nın bir ucu sabitlenmiştir ve diğer uç derin oluğu bilyalı rulman tarafından desteklenir. Avantajlar: rijitlik ile montaj zorluğu arasında denge sağlar, belirli bir eksenel yükü taşıyabilir ve orta stroklu, orta hızlı uygulamalara (örneğin genel otomasyon modülleri) uygundur.

4. Bilyalı Vida'nın Temel Teknik Göstergeleri

Temel teknik göstergeleri anlamak, bilyalı vidaların performansını değerlendirmek ve doğru ürünü seçmek için kilit öneme sahiptir. Ana teknik göstergeler aşağıdaki yönleri içerir:

-

Adım (P) : Vidanın bir tam tur döndüğünde (360°) somunun eksen boyunca aldığı doğrusal mesafe; milimetre (mm) cinsindendir. Adım, doğrudan iletim hızını (doğrusal hız = adım × devir hızı) ve konumlandırma çözünürlüğünü belirler. Yaygın adımlar 5 mm, 10 mm, 20 mm gibi değerlerdir. İnce adımlar (≤ 5 mm) yüksek hassasiyetli konumlandırmaya, kaba adımlar (≥ 20 mm) ise yüksek hızlı iletime uygundur.

-

Adım Hassasiyeti : Daha önce belirtildiği gibi, konumlandırma doğruluğunun temel indeksi olan C1-C16 sınıflarına ayrılır. Seçim yapılırken ekipmanın gerçek konumlandırma gereksinimlerine göre doğruluk sınıfı eşleştirilmelidir.

-

Eksenel Yük Kapasitesi : Top vidasının çalışma sırasında taşıyabileceği maksimum eksenel kuvvet, Newton (N) cinsindendir. Bu değer, çelik bilyanın boyutuna, bilya sayısına ve yuva profiline bağlıdır. Yük kapasitesinin aşılması erken aşınmaya ve doğruluğun azalmasına neden olur.

-

Sertlik : Yük altında deformasyona karşı direnme yeteneği; eksenel rijitlik ve radyal rijitliği içerir. Eksenel rijitlik, özellikle konumlandırma doğruluğu açısından önemlidir ve vida çapının artırılması, uygun bir montaj şekli seçilmesi veya ön gerilimin uygulanmasıyla artırılabilir.

-

Kritik Hız : İşlem sırasında vidanın rezonans üretmediği maksimum dönme hızı, devir dakikada (rpm) olarak ifade edilir. Kritik hızın aşılması, vidanın şiddetli titreşimler yapmasına neden olur ve iletim kararlılığını etkiler. Kritik hız, vidanın çapına, uzunluğuna ve montaj biçimine bağlıdır.

-

İletim Verimliliği : Giriş gücüne karşı çıkış gücünün oranı olup, bilyalı vidalarda %90-%98'e kadar çıkabilir (trapez vidalarda sadece %30-%50 arasındadır). Yüksek verimlilik, daha az enerji kaybı anlamına gelir ve bu da enerji tasarrufuna ve tahrik motoru yükünün azaltılmasına yardımcı olur.

5. Bilyalı Vidalara Dair Pratik Seçim Kılavuzu

Bilyalı vidaların doğru seçilmesi, ekipmanın performansını, kullanım ömrünü ve maliyetini doğrudan etkiler. Yüksek hassasiyet ya da düşük maliyetin körük gibi takip edilmesini önlemek için aşağıdaki faktörleri kapsamlı bir şekilde değerlendirmek gerekir:

-

Uygulama Gereksinimlerini Belirleme : İlk olarak, ekipmanın temel gereksinimlerini belirleyin. Bunlara konumlandırma doğruluğu (hassasiyet sınıfını belirler), yük kapasitesi (vida çapını ve adımı belirler), çalışma hızı (adımı ve kritik hızı belirler) ve strok (vida uzunluğunu ve montaj biçimini belirler) dahildir.

-

Uygun Dönüşüm Modunu Seçin : Yüksek hızlı, düşük gürültülü ve dar alanlı uygulamalar için iç dönüşümlü bilyalı vidaları; genel yük durumları ve düşük maliyetli uygulamalar için dış dönüşümlü bilyalı vidaları seçin.

-

Hassasiyet Sınıfını Eşleştirin : Yarı iletken ve optik cihazlar gibi ultra hassas ekipmanlar için C1-C5 yüksek hassasiyet sınıflarını; genel CNC tezgahları ve otomasyon ekipmanları için C7-C10 orta hassasiyet sınıflarını; düşük hassasiyetli iletim uygulamaları için ise C16 genel hassasiyet sınıfını seçin.

-

Montaj Biçimini Belirleyin : Uzun strok ve yüksek rijitlik gereksinimleri için sabit-sabit tipini; kısa strok ve basit montaj gereksinimleri için sabit-serbest tipini; orta strok, dengeli rijitlik ve montaj kolaylığı için sabit-destekli tipi seçin.

-

Çalışma Ortamını Dikkate Alın : Tozlu, nemli veya korozif ortamlarda labirent contalar gibi gelişmiş sızdırmazlık cihazlarına sahip bilyalı miller ve nikel kaplama, krom kaplama gibi yüzey korozyon önleyici işlemler tercih edilmelidir; yüksek sıcaklık ortamlarında ise ısıya dayanıklı malzemeler ve yağlayıcılar kullanılmalıdır.

-

Ön yük Gereksinimlerine Dikkat Edin : Yüksek rijitlik ve boşluksuz çalışma gerektiren uygulamalarda (örneğin CNC işleme merkezleri) ön yüklemeli bilyalı miller seçilmelidir (yaygın ön yükleme yöntemleri arasında çift somunlu ön yükleme, ofset ön yükleme ve hat ön yükleme bulunur); genel uygulamalar için maliyeti düşürmek amacıyla ön yüklemesiz bilyalı miller tercih edilebilir.

6. Günlük Bakım ve Ömür Uzatma İpuçları

Top vida milinin ömrünü etkili bir şekilde uzatmak ve hassasiyetini korumak için düzenli bakım yapılmalıdır. Ana bakım noktaları şunlardır:

-

Düzenli yağlama : Oluşan sürtünmeyi azaltmak için bilyeler ve yataklar arasına düzenli olarak yağ veya gres eklenmelidir. Yağ türü, çalışma hızına ve sıcaklığına göre seçilmelidir (yüksek hızlı uygulamalarda yağ, düşük hızlı yüksek yük uygulamalarında gres tercih edilir). Her 200-500 saatlik çalışma süresinden sonra yağlama yapılması önerilir.

-

Sızdırmazlık ve Toz Önleme : Sızdırmazlık sistemi düzenli olarak kontrol edilmeli, hasarsız ve işlevsel olduğundan emin olunmalıdır. Vida ve somun yüzeyleri zamanında temizlenerek partiküllerin yuva içine girmesi önlenmelidir. Zorlu ortamlar için ek koruyucu kapaklar (örneğin teleskopik kapaklar) takılabilir.

-

Düzenli Hassasiyet Kontrolü : Topuz vidasının konumlandırma doğruluğunu ve hatasını düzenli olarak kontrol etmek için saat ölçerler ve lazer interferometreler gibi araçlar kullanın. Eğer hassasiyet izin verilen aralığı aşarsa, topuz vidayı zamanında ayarlayın veya değiştirin.

-

Aşırı yükleme altında çalışmayı önleyin : Topuz vidasının nominal aralığında yükü ve hızı kesinlikle kontrol edin; aşırı yük veya aşırı hız nedeniyle erken aşınma veya hasar oluşmasını önleyin.

Sonuç

Toplu mili, mekanik iletimin "hassas çekirdeği" olarak, endüstriyel otomasyon ve yüksek hassasiyetli ekipmanlarda yerine geçilmez bir rol oynar. Kesin tanımı ve yapısal bileşenlerinden bilimsel sınıflandırmaya ve hassasiyet derecelendirmesine kadar her bağlantı, profesyonel teknik içeriğini yansıtır. Toplu millerin seçiminde ve uygulanmasında uygulama gereksinimleri, çalışma ortamı ve maliyet faktörleri kapsamlı bir şekilde dikkate alınmalı ve uygun özelliklere ve performansa sahip ürünlerle eşleştirme yapılmalıdır. Aynı zamanda standartlara uygun günlük bakım, toplu millerin uzun süreli kararlı çalışmasını sağlayabilir.

Mekanik tasarım ve otomasyonla ilgilenen mühendisler ve teknik personel için, bilyalı vida bilgisine derinlemesine hakim olmak, ekipman performansını artırmak ve arıza oranlarını düşürmek açısından temel bir gerekliliktir. Endüstriyel otomasyonun sürekli gelişmesiyle birlikte bilyalı vidalar daha yüksek hassasiyet, daha yüksek hız ve çevre uyumlarında daha fazla esneklik doğrultusunda ilerleyecek ve imalat sanayisinin akıllı dönüşümüne daha güçlü destek sağlayacaktır.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ