To ensure the high precision and long-term stable operation of THK BNFN7020-5 ball screws, regular maintenance is essential. First, apply the appropriate grease periodically based on the working environment and usage frequency to prevent dry friction and wear. Second, check for unusual noise or increased backlash between the screw and nut, and address any issues promptly. In addition, clean the screw shaft regularly to remove dust, chips, and other contaminants that may enter the raceway and affect transmission accuracy. When the equipment is idle for long periods, use anti-rust measures such as applying protective film. With proper maintenance, THK BNFN7020-5 ball screws can achieve longer service life, higher operational efficiency, and reduced equipment downtime and costs.

Product Information | |

Product Name |

THK BNFN7020-5 Ball Screw |

Material |

Bearing steel, harden steel, chrome steel, stainless steel |

Accuracy |

C3 C5 C7 C10 |

Application |

1.Machine tools and machining centers

2.Semiconductor manufacturing equipment

3.Industrial robots

4.Medical equipment

5.Precision measurement and testing equipment

6.Factory automation and material handling

|

Features |

a. High speed b. High rigidity c. Low noise d. Precision grinding e. Precision positioning f. Double nut |

Model No. |

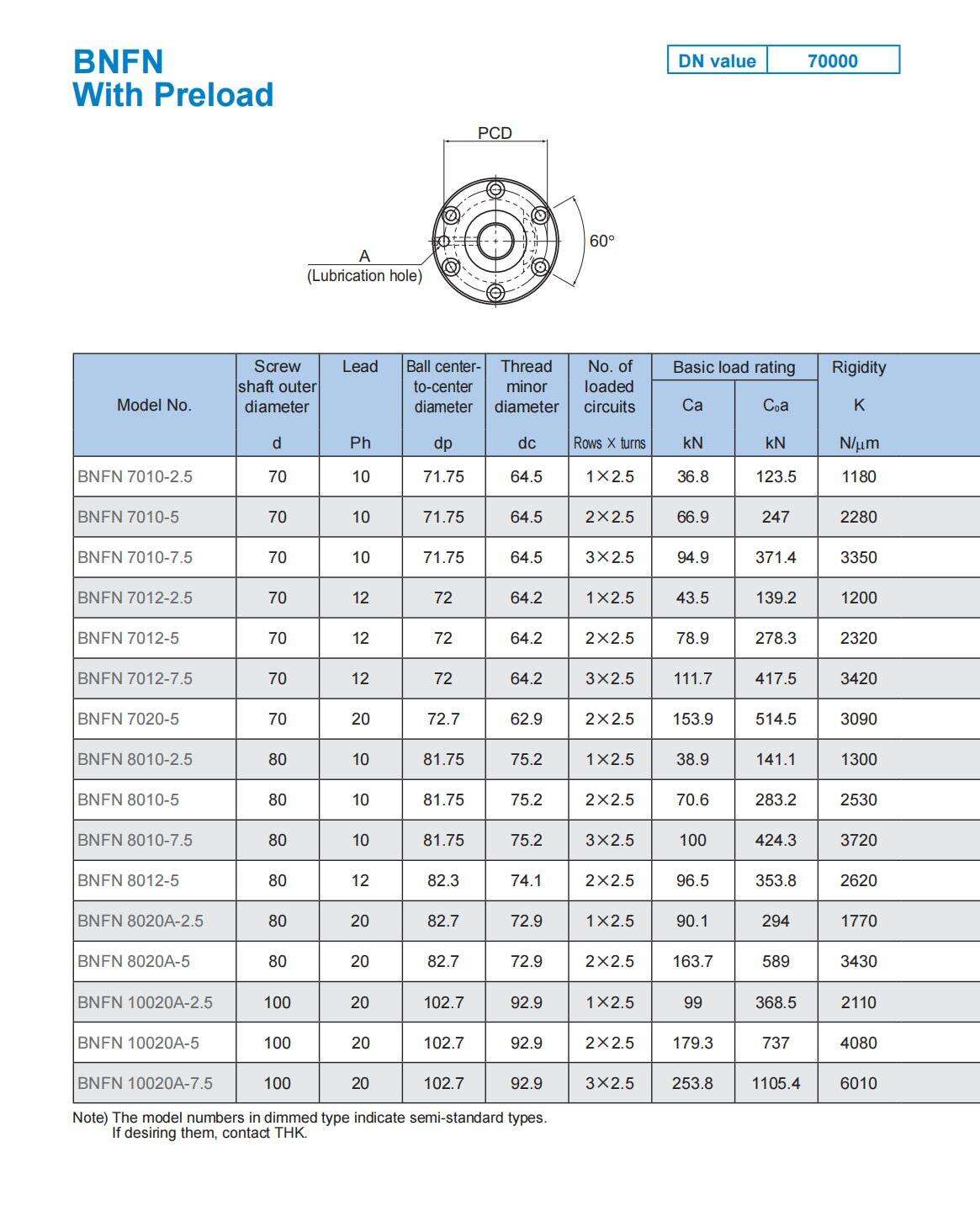

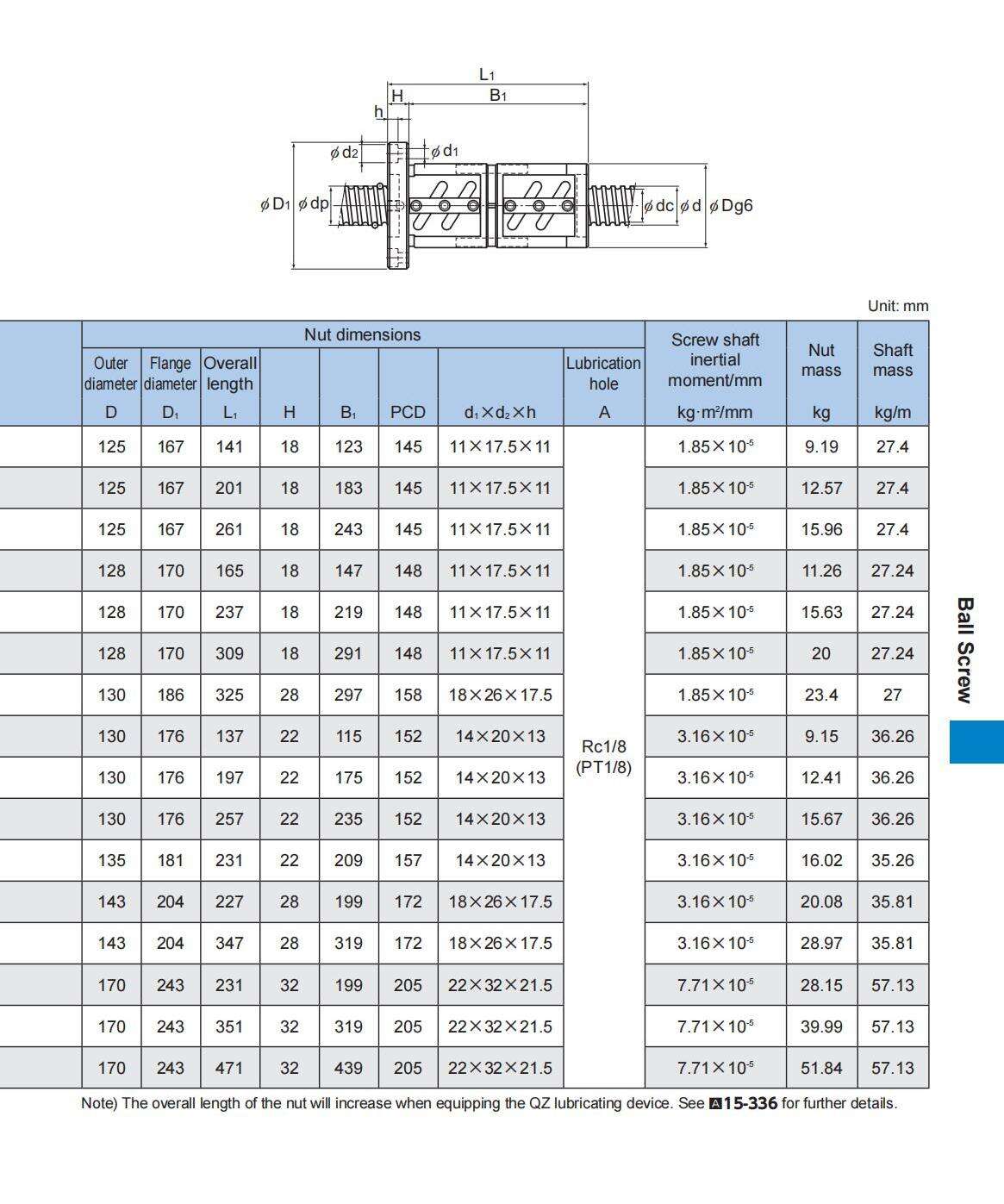

BNFN 5510-2.5 BNFN 5510-5 BNFN 5510-7.5 BNFN 5512-2.5 BNFN 5512-3 BNFN 5512-3.5 BNFN 5512-5 BNFN 5512-7.5 BNFN 5516-2.5 BNFN 5516-5 BNFN 5520-2.5 BNFN 5520-5 BNFN 6310-2.5 BNFN 6310-5 BNFN 6310-7.5 BNFN 6312A-2.5 BNFN 6312A-5 BNFN 6316-2.5 BNFN 6316-5 BNFN 6320-2.5 BNFN 6320-5 BNFN 7010-2.5 BNFN 7010-5 BNFN 7010-7.5 BNFN 7012-2.5 BNFN 7012-5 BNFN 7012-7.5 BNFN 7020-5 BNFN 8010-2.5 BNFN 8010-5 BNFN 8010-7.5 BNFN 8012-5 BNFN 8020A-2.5 BNFN 8020A-5 BNFN 10020A-2.5 BNFN 10020A-5 BNFN 10020A-7.5 |

Our services |

According to drawings or samples for our customers to manufacture products. |

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

Delivery time |

3~7 days for sample order, 15~20 days for bulk order. Depends on the actual shipping situation. |

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved