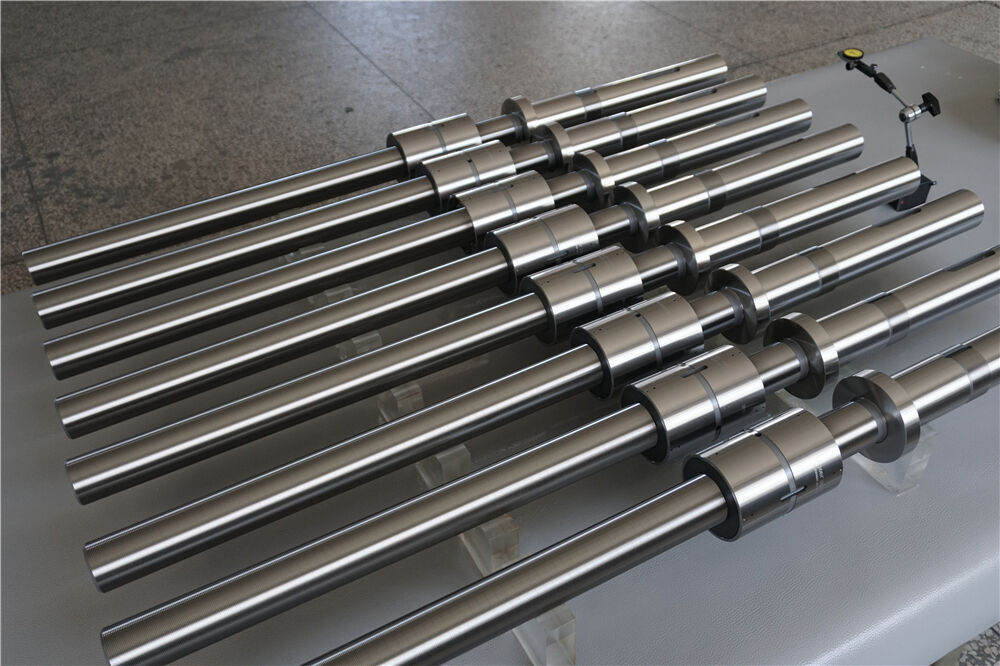

In the pursuit of high load capacity, extreme precision, and long service life in industrial automation, planetary roller screws stand out as the "king of screws" and redefine the benchmarks for linear motion transmission. Unlike traditional ball screws and trapezoidal screws, planetary roller screws leverage multi-point line contact between threaded rollers and the screw shaft to deliver unmatched performance, making them indispensable in cutting-edge fields such as aerospace, heavy machinery, and medical equipment. This article delves into the core advantages, technical differences, selection guidelines, and real-world applications of planetary roller screws, helping you unlock optimal performance for demanding automation projects.

I. Core Advantages of Planetary Roller Screws: Beyond Traditional Linear Motion Solutions

Planetary roller screws’ superior performance stems from their innovative structural design, which addresses the limitations of conventional screws. Their key advantages are as follows:

1. Exceptional Load Capacity & Rigidity

Unlike ball screws that rely on point contact, planetary roller screws use line contact between multiple planetary rollers and the screw shaft. This design distributes loads across a larger contact area, enabling them to withstand static loads up to 3 times that of ball screws of the same size, with some models boasting rated dynamic loads exceeding 1000kN. The enhanced contact also delivers outstanding axial rigidity, eliminating deformation under heavy loads and ensuring stable precision in high-pressure scenarios like injection molding machine clamping systems and heavy machine tool feed mechanisms.

2. Extended Service Life & Impact Resistance

By evenly distributing stress across the contact lines, planetary roller screws minimize localized wear and tear. According to Hertz’s pressure law, their service life is 15 times longer than that of ball screws, significantly reducing downtime and maintenance costs. Additionally, the robust roller structure exhibits strong impact resistance, making them reliable in harsh working conditions with alternating loads or sudden impacts, such as wind turbine pitch control systems and missile launcher adjustments.

3. Compact Size & Flexible Lead Design

Under the same load requirements, planetary roller screws occupy 1/3 less space than ball screws, making them ideal for equipment with limited installation space. Their lead (linear displacement per rotation) is not restricted by roller diameter, allowing for ultra-small leads (less than 0.5mm) or custom decimal leads (e.g., 3.32mm per rotation). This eliminates the need for additional reduction gears, simplifying system design while maintaining high precision micro-feeding capabilities.

4. High Speed & Low Noise Operation

Free from the DN value constraints of ball return mechanisms, planetary roller screws achieve maximum linear speeds of 2000mm/s and rotational speeds up to 5000rpm, with accelerations reaching 3g. The smooth rolling motion between rollers and the screw shaft generates minimal vibration and noise, meeting the quiet operation requirements of clean rooms, semiconductor equipment, and medical devices.

5. High Precision & Environmental Adaptability

The non-circular thread design of the screw shaft facilitates exceptional lead precision, with standard accuracy grades (KL10) achieving ±0.01mm over a 315mm stroke and high-precision grades (KL5) reaching ±0.005mm. Moreover, they perform reliably in harsh environments—resisting low temperatures, dust, chemical deposits, and even lubrication shortages—outperforming ball screws in extreme industrial settings.

II. Planetary Roller Screws vs. Ball Screws vs. Trapezoidal Screws: Key Performance Comparison

Choosing the right linear motion component depends on balancing load, precision, speed, and cost. Here’s a detailed comparison of three mainstream screw types:

Trapezoidal Screws: Cost-Effective for Low-Precision Heavy Loads

Trapezoidal screws use sliding friction, offering strong self-locking capabilities for vertical loads (no additional braking required) and low maintenance costs. However, their transmission efficiency is only 30%-50%, limiting speeds to ≤100rpm, and positioning accuracy (±0.1mm-±0.5mm) is far lower than planetary and ball screws. They are suitable for low-cost, low-precision applications like lift platforms and gate controls.

Ball Screws: High Efficiency for Standard Precision Scenarios

Ball screws deliver 85%-95% transmission efficiency and precision down to ±0.01mm, making them ideal for general automation equipment. Yet, their point contact design limits load capacity (up to 100kN) and impact resistance, with a shorter service life than planetary roller screws. They also lack self-locking, requiring additional brakes for vertical operation, increasing system complexity.

Planetary Roller Screws: Heavy-Duty Precision for Demanding Applications

Planetary roller screws combine the high precision of ball screws with the load capacity of trapezoidal screws, offering 80%-90% efficiency, 200kN-1000kN load capacity, and ±0.02mm-±0.1mm precision. While they lack self-locking and have higher procurement costs (3-5 times that of ball screws), their long service life and reliability justify the investment in high-end applications requiring both heavy loads and precision.

III. Expert Selection Guide for Planetary Roller Screws

Selecting the right planetary roller screw requires evaluating key application parameters to ensure optimal performance. Follow these steps:

1. Define Core Application Requirements

First, clarify load parameters (static/dynamic load, impact load), motion indicators (speed, acceleration, stroke length), precision demands (lead accuracy, repeat positioning error), and environmental conditions (temperature, dust, lubrication availability). For example, aerospace applications require extreme reliability and temperature resistance, while semiconductor equipment prioritizes precision and low particle generation.

2. Choose the Right Screw Type & Nut Configuration

Planetary roller screws are classified into non-circulating (RGT/RGTB series) and circulating (RGTR series) types, with reverse models (RGTI series) available for specific applications. Select nut configurations (single nut, double nut, preloaded nut) based on rigidity needs—preloaded nuts eliminate backlash for high-precision positioning, while single nuts suit general load scenarios.

3. Calculate Load Capacity & Service Life

Use Hertz’s pressure law to calculate equivalent dynamic load and rated service life, accounting for load distribution and operating conditions. Ensure the selected screw’s rated load exceeds the maximum working load by a safety margin, and verify service life aligns with equipment maintenance cycles to avoid premature failure.

4. Consider Installation & Maintenance Factors

Planetary roller screws feature integrated nut assemblies that simplify installation (components won’t scatter when separated from the shaft). For vertical applications, install mandatory braking devices to compensate for lack of self-locking. Regular maintenance—including lubrication checks and roller wear inspections—extends service life, especially in harsh environments.

IV. Key Application Scenarios of Planetary Roller Screws

Planetary roller screws excel in demanding environments where performance and reliability are critical. Typical applications include:

-

Aerospace & Defense: Aircraft flap controls, missile launcher adjustments, and drone landing gear—leveraging high reliability and extreme environmental resistance.

-

Heavy Machinery: Large injection molding machines, metal die-casting machines, and heavy机床 feed systems—handling high clamping forces and heavy loads.

-

Semiconductor & Electronics: Lithography machines and wafer transfer robots—delivering precision micro-feeding and clean operation.

-

Automotive & New Energy: EV electronic brake systems, active suspensions, and wind turbine pitch controls—combining fast response and high load capacity.

-

Medical Equipment: CT/MRI scanner positioning and surgical robots—offering quiet, precise motion and no hydraulic leakage risks.

V. Conclusion: The Future of Precision Linear Motion

As industrial automation advances toward heavier loads, higher precision, and longer service cycles, planetary roller screws are poised to become the preferred linear motion solution in high-end manufacturing. While their cost and complexity limit widespread adoption in general applications, their unmatched performance makes them irreplaceable in aerospace, robotics, and heavy machinery. By following scientific selection and maintenance practices, planetary roller screws can significantly enhance equipment reliability and operational efficiency.

Are you seeking a planetary roller screw solution for your heavy-duty precision application? Share your project requirements, and our experts will provide tailored recommendations.

Table of Contents

- I. Core Advantages of Planetary Roller Screws: Beyond Traditional Linear Motion Solutions

- II. Planetary Roller Screws vs. Ball Screws vs. Trapezoidal Screws: Key Performance Comparison

- III. Expert Selection Guide for Planetary Roller Screws

- IV. Key Application Scenarios of Planetary Roller Screws

- V. Conclusion: The Future of Precision Linear Motion

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ