With automation and precision manufacturing sweeping the globe, ball screws, as key components for converting rotary motion into linear motion, are of undeniable importance. As their applications expand from precise laboratories to large-scale industrial sites, medium- and large ball screws play an indispensable role. They are not only a symbol of strength but also an extension of precision in heavy-load applications. This article will delve into the unique features of medium- and large-scale ball screws and their wide range of applications.

1. What are medium- and large-scale ball screws? Analysis of Core Features

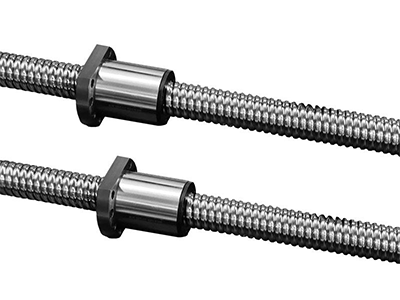

Generally, ball screws with a nominal diameter of 20mm or more are classified as medium- and large-scale ball screws. Unlike small ball screws that prioritize high speed, their design focuses on high load capacity, high rigidity, and high reliability.

Strong Load Capacity: Their larger shaft diameter and multi-row ball recirculation design allow them to withstand axial loads of several tons or even tens of tons, easily driving heavy workbenches and large components.

Excellent System Rigidity: Under heavy loads, deformation is the natural enemy of precision. Medium- and large-sized ball screws utilize optimized structural design and pre-tensioned installation technology to significantly enhance system rigidity, ensuring stability under significant external forces.

Complex Manufacturing Process: Their heat treatment, grinding, and assembly processes are far more complex than those of small ball screws, ensuring long life and high-precision retention under demanding operating conditions.

Wide Application Scenarios for Medium- and Large-sized Ball Screws

Heavy-duty CNC machine tools: On large gantry milling machines and machining centers, medium- and large-sized ball screws are the core of driving each axis, ensuring high-precision machining of aerospace components and large molds under heavy cutting conditions.

Injection molding and die-casting equipment: As the power source for the mold clamping unit, they provide tremendous and precise clamping force, making them key to efficient and energy-saving production.

Automated Logistics and Handling: From aisle stackers in automated warehouses to handling robots, medium- and large-sized ball screws ensure precise positioning and enormous load capacity at high speeds.

New Energy and Heavy Industry: They operate stably and reliably in wind turbine pitch and yaw systems, solar tracking systems, and steel rolling equipment, withstanding harsh environmental conditions.

Testing and Lifting Equipment: Universal material testing machines use them to apply precise loads, while large stage elevators and car lifts rely on their powerful lifting force to ensure safe operation.

In short, medium- and large-sized ball screws are the key link between power and motion, concept and reality. With their robust load capacity, excellent rigidity, and reliable durability, they have become an indispensable core component in the high-end equipment manufacturing industry. As the industrial trend towards larger, heavier, and more precise components continues, the technology and applications of medium- and large-sized ball screws will continue to evolve, providing a solid linear power foundation for the vigorous development of modern industry.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ