Did you ever think about, how machine can make things with such precision? It’s really fascinating! The Tsugami Ball Screw One crucial part that allows machines to do this with such a high level of reliability is the ball screw, from an excellent brand called Tsugami. This cool factor enables machines to slide smoothly and accurately, a critical component of producing detailed and accurate parts.

Machines such as lathes and milling machines predominantly use ball screws. Here are those machines, that must be running on the right way when they producing parts for different products. Tsugami CNC Swiss Screw Machines - These machines use the Tsugami ball screw because it is a respected brand known for quality strength, durability and precision. As a result, assemblies of parts created by machines utilizing Tsugami ball screws will slip right into place.

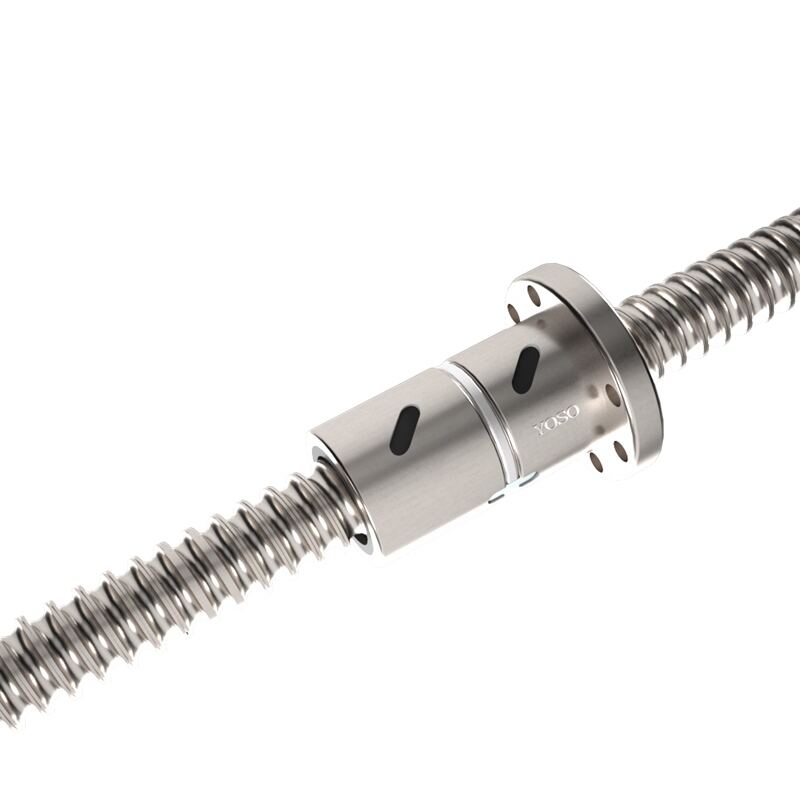

A ball screw, in simple terms is a long rod containing and spiral groove inside. This groove is known as the raceway. Step 2: Disassemble the groove There are some small balls inside that help with the smooth movement of this rod As the rod is turned, these tiny balls travel in and out of grooves on it to provide near-frictionless movement with extreme precision. The machine uses a TSUGAMI ball screw, so it will not wobble or shake during operation which is important to create quality products.

Friction itself is one of the factors that can create wear and tear on machines. Friction: When two parts rub together, they wear against each other and the act of doing so slowly wears them down. Those tiny balls that it uses roll the cogs of the Tsugami ball screw, reducing friction. The rolling motion means more of a chance for less resistance and in turn this equates to less friction between machine parts.

Dirt and debris: Dirt, dust bunnies are a big release demo another culprit for slots that won't turn. It can be a problem when dust and particles are inadvertently brought into the machines. The great news is that the Tsugami ball screw cleans itself! This can help to prevent dirt or other debris from getting stuck inside the machine and keep it running smoothly.

Machines can be great, but only if they are given the right building blocks to thrive on. This helps the machines in being precise, durable and perform efficiently over time courtesy of Tsugami ball screw. The use of the Tsugami ball screw in machines allows to manufacture very accurate parts. This enables them to produce perfectly-sized, shaped parts every time.

This is a reason why the ball screws are made using very strong materials to avoid any thermal twist under harsh temperatures which these devices usually experience in real time or environment side upper from freezing cold until super hot above gas melting points and even more. It also won't rust or corrode, keeping it operating in challenging environments. This robustness allows a machine to continue operating effectively when confronted with all types of operational difficulties.

YOSO is specialist all types mechanical transmissions. new, large-scale 6-meter CNC production line provide 6-meter guide rail batches. guide rails be as big Tsugami ball screw. Guide rails mass-produced the full series 25, 30 35 45, 55, 65, 85 100, 125. single slider carry a maximum weight 192t. screw production base able produce batches a minimum diameter Ph6mm an a average lead 1mm a maximum diameter Ph245mm, single screw length 10m an a rated maximum dynamic load 125 tons. It make ball screw pairs different sizes, such 2-meter 3-meter C1 levels batches, five-meter level C3 10-meter level C5.YOSO Motion, best partner linear systems. We work you aid Industry 4.0.Change perspective Made China different.

Brand : 10 years international exhibition participationTsugami ball screw at heart sustainable development.Service : Customers partnersSolutions TransmissionYOSO trained professionals in field transmissioncomponents within company perfectly analyzecustomer drawing requiremenis 3D finished productmodels facilitate production arrangements.Industry ExchangeYOSO is major partner industry events held throughout world participant these. exchanges betweenpractitioners forward-looking applicationentrepreneurship leading companies importantsoil our growth.

Jingpeng Machinery founded 2015 its headquarters Shanghai will establish a EU branch Poland 2022. Jingpeng Machinery continue deepen presence the world.Ten years later, YOSO now fully integrated trade industry platform mechanical transmissions own trademark international patents. Jingpeng stuck a corporate style emphasizes "brand quality, service brand" since beginning.YOSO brand enables us attend international exhibitions in field every year. Quality at heart YOSO's long-term development. Service allows customers become Tsugami ball screw partners.Jingpeng Machinery is leading marketplace buy industrial 4.0 mechanical gearboxes. trust built 10 years producing perfect products, 190 engineering professionals who are practicing, 24 modern production line, 50,000m2 base production. Every mechanical transmission variety carefully selected manufacturing methods. YOSO Committed produces perfect products.

Multi-product Integration Tsugami ball screwYOSO We offer complete control transmission components One-stop-shop products meet requirementsour customers. We're committed helping clients compete in marketplace through providing technological solutions, factory efficiency, brand marketing power product quality.We offer product range wide selection superior performance have earned trust in market due our deep understanding customer requirements.Partners around world established closer relationships YOSO, and internationalization strategy YOSO brand dealers reach customers their regions through global network. Contact me you interested becoming involved!

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved