Product Information | |

Product Name |

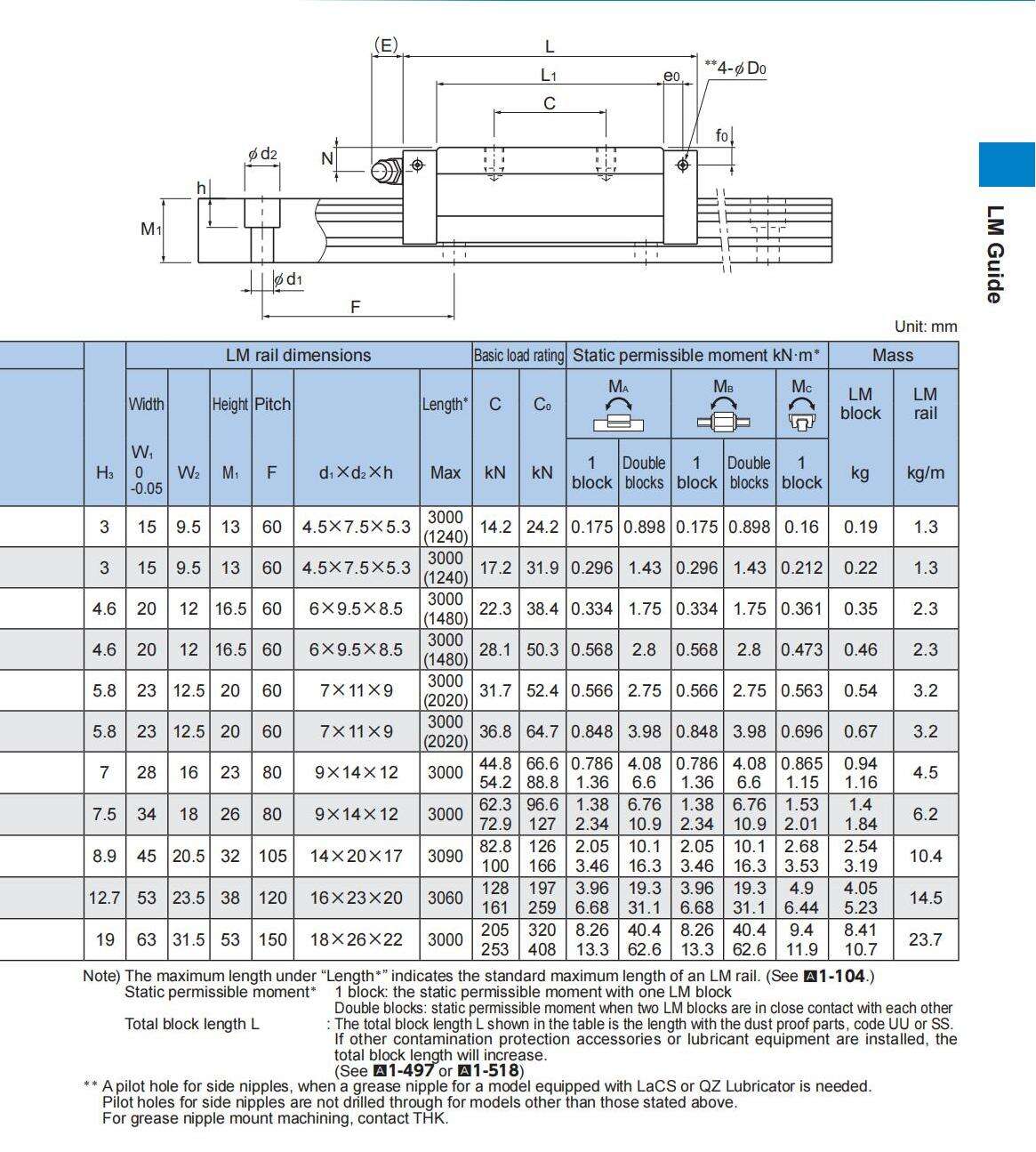

THK SHS55V Linear Guide |

Length |

Customized Length |

Features |

|

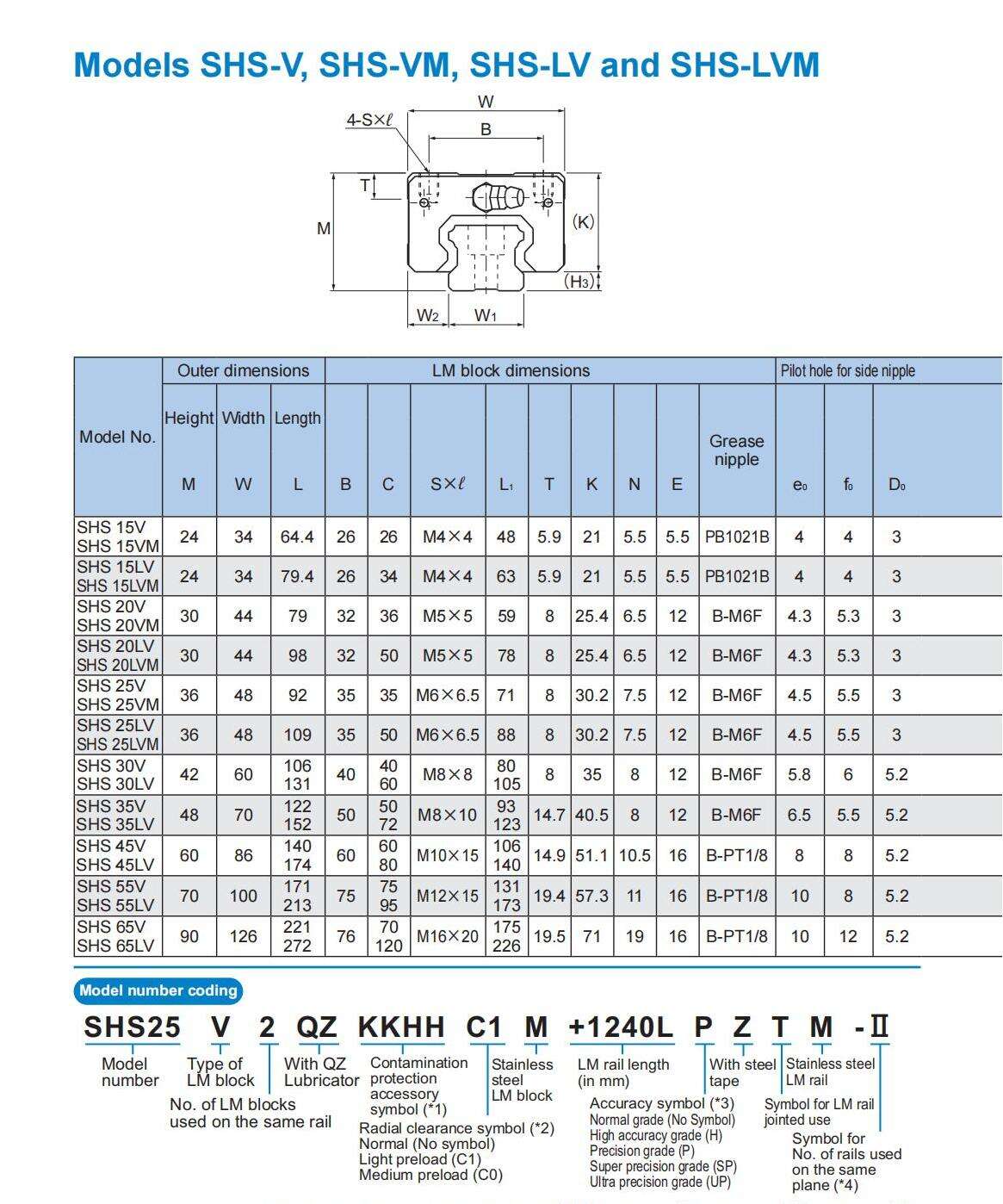

Type |

SHS-V SHS-LV |

Model No. |

SHS15V SHS15M SHS15LV SHS15LVM SHS20V SHS20VM SHS20LV SHS20LVM SHS25V SHS25VM SHS25LV SHS25LVM SHS30V SHS30LV SHS35V SHS35LV SHS45V SHS45LV SHS55V SHS55LV SHS65V SHS65LV |

Material |

Carbon Steel |

Core Components |

Slider、 Guide |

Typical application scenarios |

a. Precision machine tools b. Semiconductor manufacturing equipment c. Automated production lines d. Medical equipment e. Optical instruments |

Our services |

According to drawings or samples for our customers to manufacture products. |

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved