Maintenance and care: In order to ensure that the HIWIN QEW35CB linear guide maintains good performance for a long time, correct maintenance and care are essential. First of all, keep the surface of the guide clean, regularly clean the dust, debris and other impurities on the guide to prevent these impurities from entering the gap between the slider and the guide and aggravating the wear. You can use special cleaning tools and detergents for cleaning. Secondly, lubricate the guide regularly, choose a suitable lubricant, and lubricate according to the prescribed lubrication cycle and lubrication method to reduce the friction between the slider and the guide, reduce wear, and improve the smoothness of the movement of the guide. In addition, it is necessary to regularly check the installation status of the guide to ensure that the mounting bolts and other connectors of the guide are not loose, and the straightness and parallelism of the guide have not changed. If the guide is found to be worn, deformed, etc., it should be repaired or replaced in time to ensure the normal operation of the equipment.

Product Information | |

Product Name |

HIWIN QEW35CB Linear Guide |

Material |

Steel |

Length |

Customized Length |

Model No. |

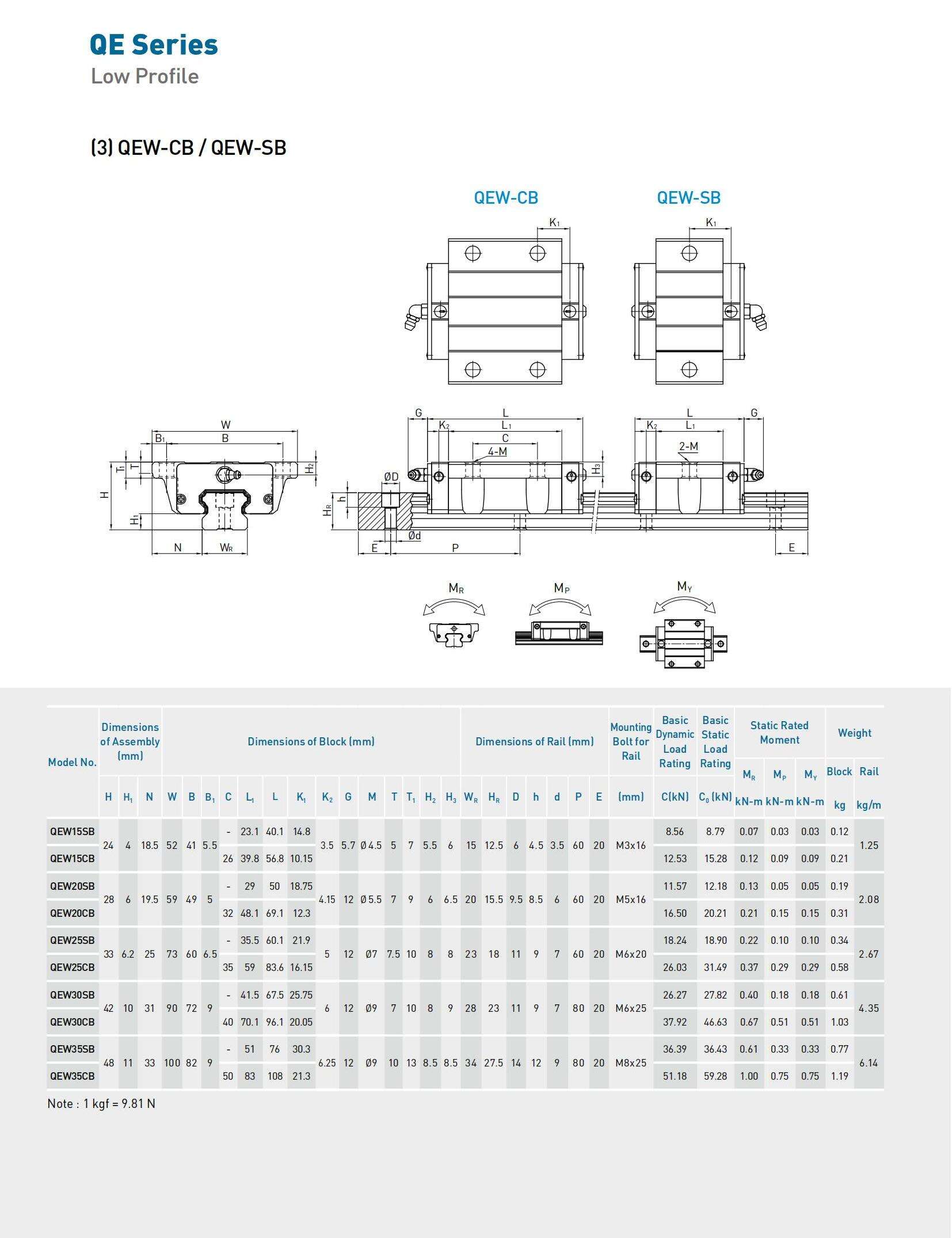

QEW15SB QEW15CB QEW20SB QEW20CB QEW25SB QEW25CB QEW30SB QEW30CB QEW35SB QEW35CB |

Our services |

According to drawings or samples for our customers to manufacture products. |

Product Package |

a. Plastic bag with box case or wooden case. We can provide shipping information to our customer at any time. |

Typical application scenarios |

a. Medical equipment b. Semiconductor and electronics manufacturing c. Precision instruments and laboratory equipment d. Optoelectronics and 3C industry e. Automation and precision machinery industry |

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd All Rights Reserved