Ý nghĩa mô hình:

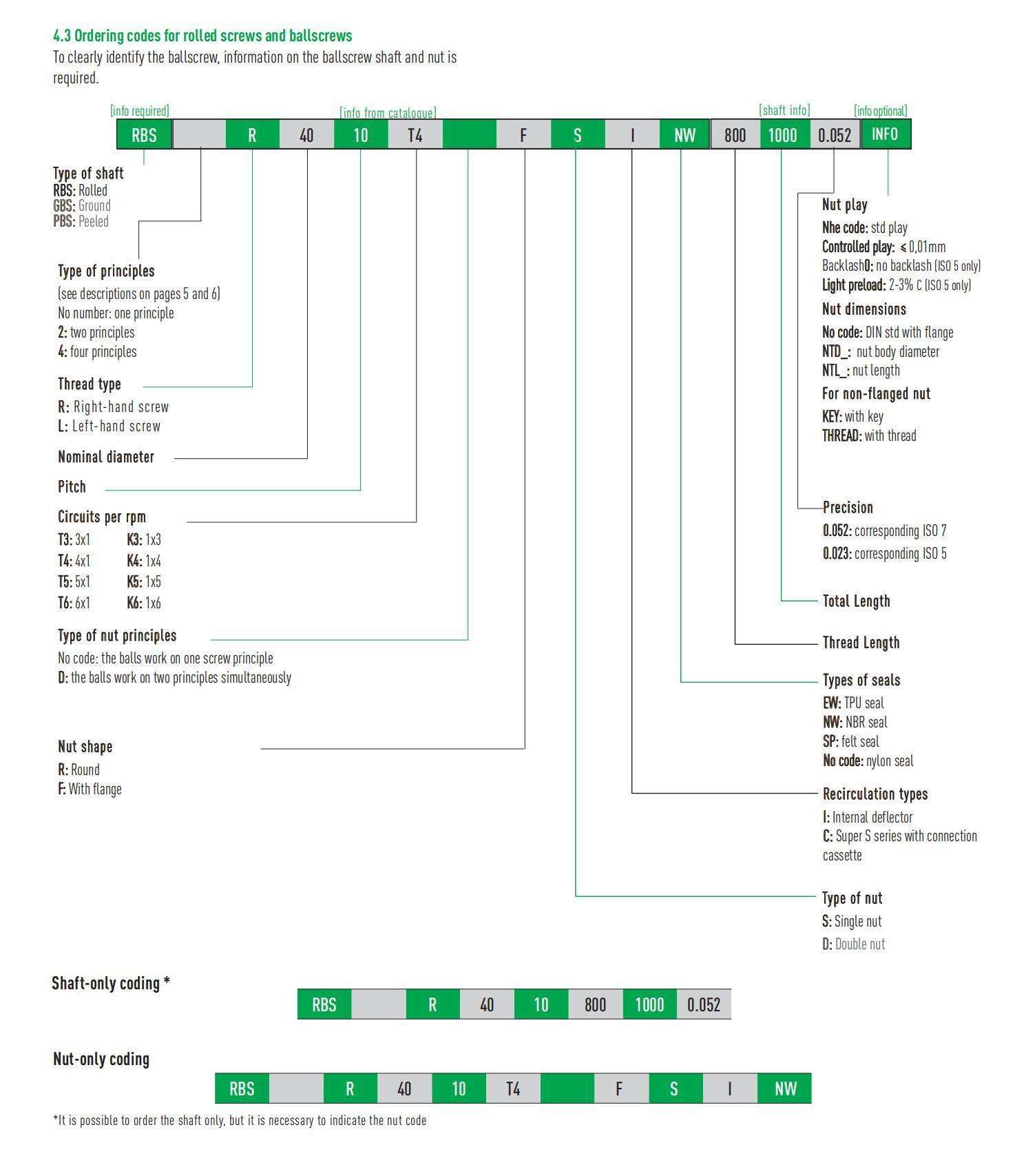

“R”: Chỉ trục vít bi quay thuận chiều kim đồng hồ (quay bên phải).

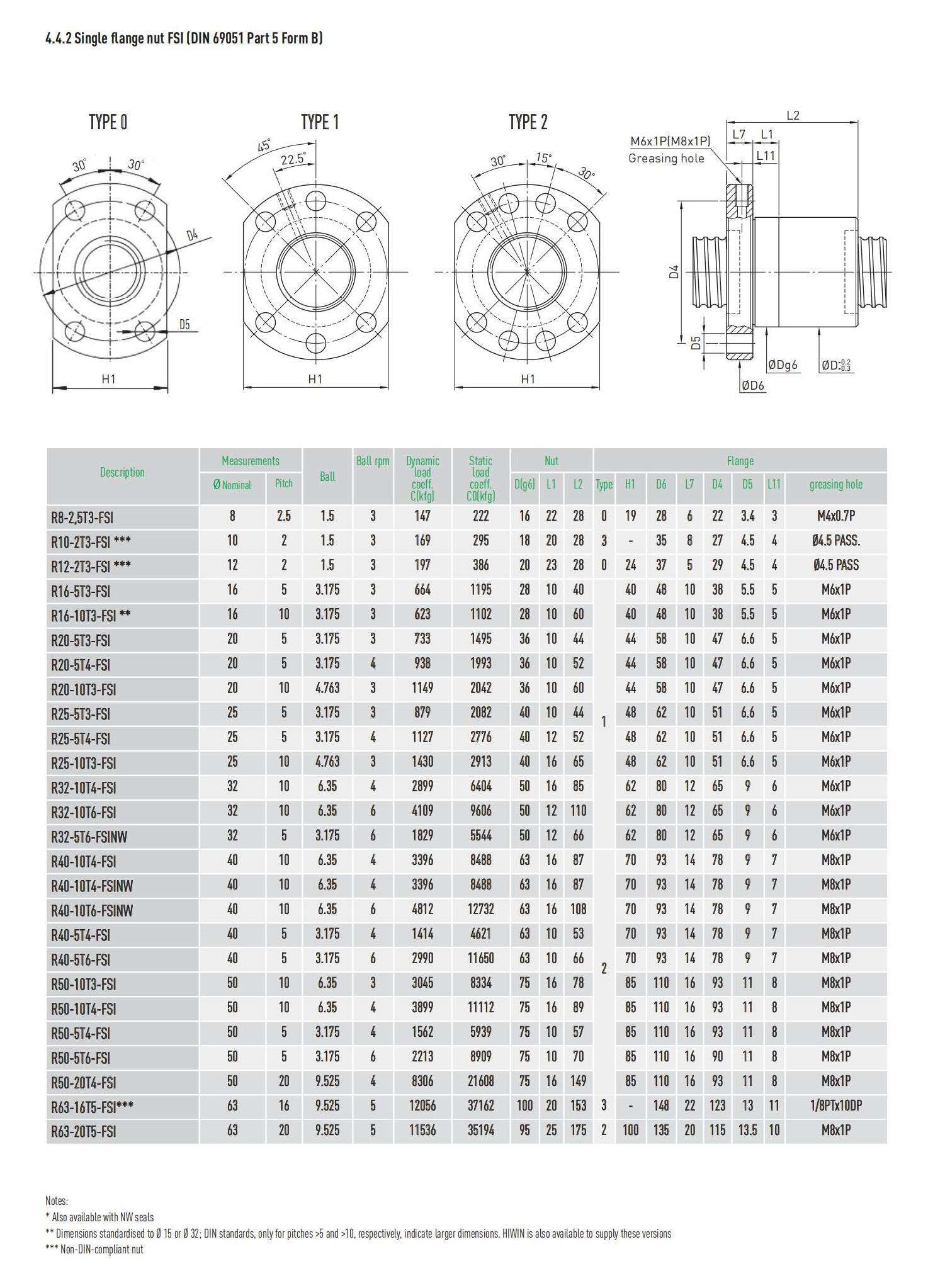

"25": Đại diện cho đường kính danh nghĩa 25mm.

"5": Chỉ độ dài bước vít 2,5mm, nghĩa là đai ốc di chuyển 5mm dọc theo trục vít cho mỗi vòng xoay của vít.

“T3”: 3×1

“FSI”: “F”: Đai ốc gắn mặt bích, “S”: Đai ốc đơn, và “I”: Tuần hoàn bên trong.

Trong quá trình sử dụng vít bi HIWIN R25-5T3-FSI, việc bảo trì hàng ngày là rất cần thiết để duy trì độ chính xác cao và tuổi thọ lâu dài. Dưới đây là các điểm bảo trì dành cho dòng vít bi FSI series, có thể được tham khảo bởi đa số nhân viên bảo trì và người mua thiết bị công nghiệp:

1. Bôi trơn định kỳ

Các bộ phận tiếp xúc bằng bi lăn của vít bi cần được bôi trơn tốt để giảm ma sát và mài mòn. Nên bổ sung mỡ hoặc dầu bôi trơn phù hợp định kỳ, và điều chỉnh chu kỳ bôi trơn theo tốc độ vận hành, nhiệt độ môi trường và điều kiện tải trọng. Tăng tần suất bôi trơn trong môi trường khô hoặc nhiều bụi.

2. Làm sạch bề mặt vít

Bề mặt của trục vít cần được giữ sạch sẽ để tránh bụi, mạt kim loại và các tạp chất khác xâm nhập vào đai ốc, gây kẹt bi hoặc trầy xước bề mặt. Có thể lau bằng khăn mềm không xơ và không có cặn bã, đồng thời có thể sử dụng chất làm sạch chuyên dụng.

3. Chống gỉ

Nếu trục vít FSI được lắp đặt trong môi trường có độ ẩm cao, cần thường xuyên kiểm tra dấu hiệu gỉ sét, đồng thời tra dầu chống gỉ hoặc sử dụng chất bôi trơn có khả năng chống gỉ.

4. Kiểm tra tình trạng vận hành

Thường xuyên quan sát âm thanh của trục vít có ổn định không, có rung động bất thường, bị kẹt hoặc tiếng ồn hay không. Nếu phát hiện bất thường, cần kịp thời kiểm tra các vấn đề như sai lệch tâm, bi rơi ra hoặc thất bại trong bôi trơn.

5. Kiểm tra siết chặt và lắp đặt

Kiểm tra xem các bộ phận lắp đặt như đế đỡ vít và đai ốc khóa có bị lỏng hay không. Do cấu trúc tuần hoàn nội bộ, trục vít FSI phụ thuộc nhiều hơn vào môi trường lắp đặt ổn định để đảm bảo hiệu suất truyền động.

Bảo trì định kỳ không chỉ kéo dài tuổi thọ của trục bi FSI HIWIN, mà còn duy trì tính ổn định và độ chính xác trong hoạt động của thiết bị. Đây là một khâu quan trọng không thể bỏ qua trong quản lý thiết bị.

Bản quyền © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd. Tất cả các quyền được bảo lưu