Trong tự động hóa sản xuất, các hướng dẫn tuyến tính và hướng dẫn trượt là cốt lõi của chuyển động tuyến tính chính xác—việc lựa chọn đúng loại sẽ ảnh hưởng trực tiếp đến độ chính xác, sự ổn định và tuổi thọ thiết bị của bạn. Rất nhiều kỹ sư nhầm lẫn giữa hướng dẫn tuyến tính và hướng dẫn trượt, cho rằng chúng có thể thay thế được cho nhau. Tuy nhiên, hai loại này lại khác biệt rõ rệt về cấu trúc, hiệu suất và trường hợp sử dụng. Bài viết này sẽ phân tích những điểm khác biệt chính giữa hướng dẫn tuyến tính và hướng dẫn trượt để giúp việc lựa chọn trở nên đơn giản hơn.

I. Định nghĩa cơ bản: Nguyên lý chuyển động quyết định sự khác biệt cốt lõi

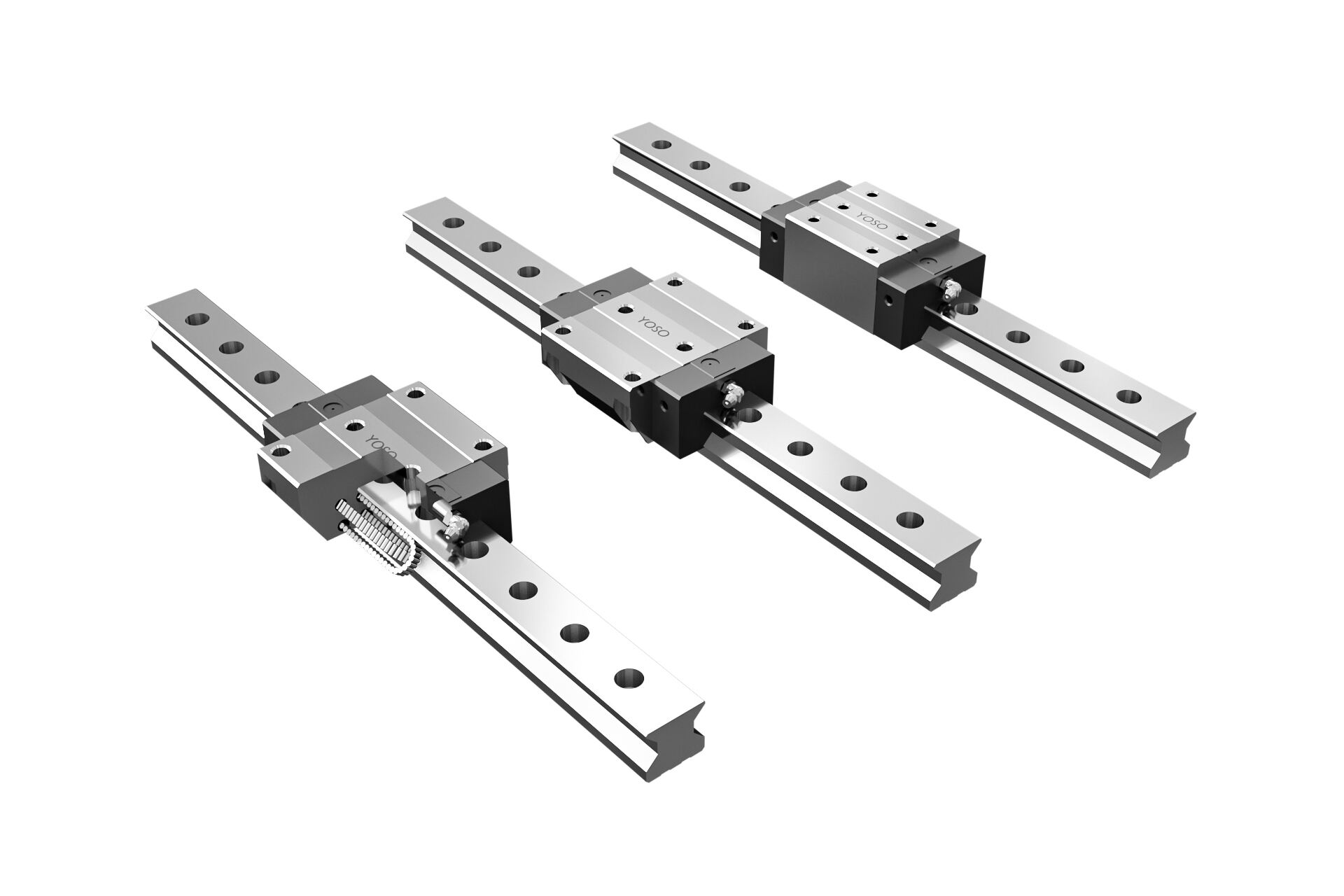

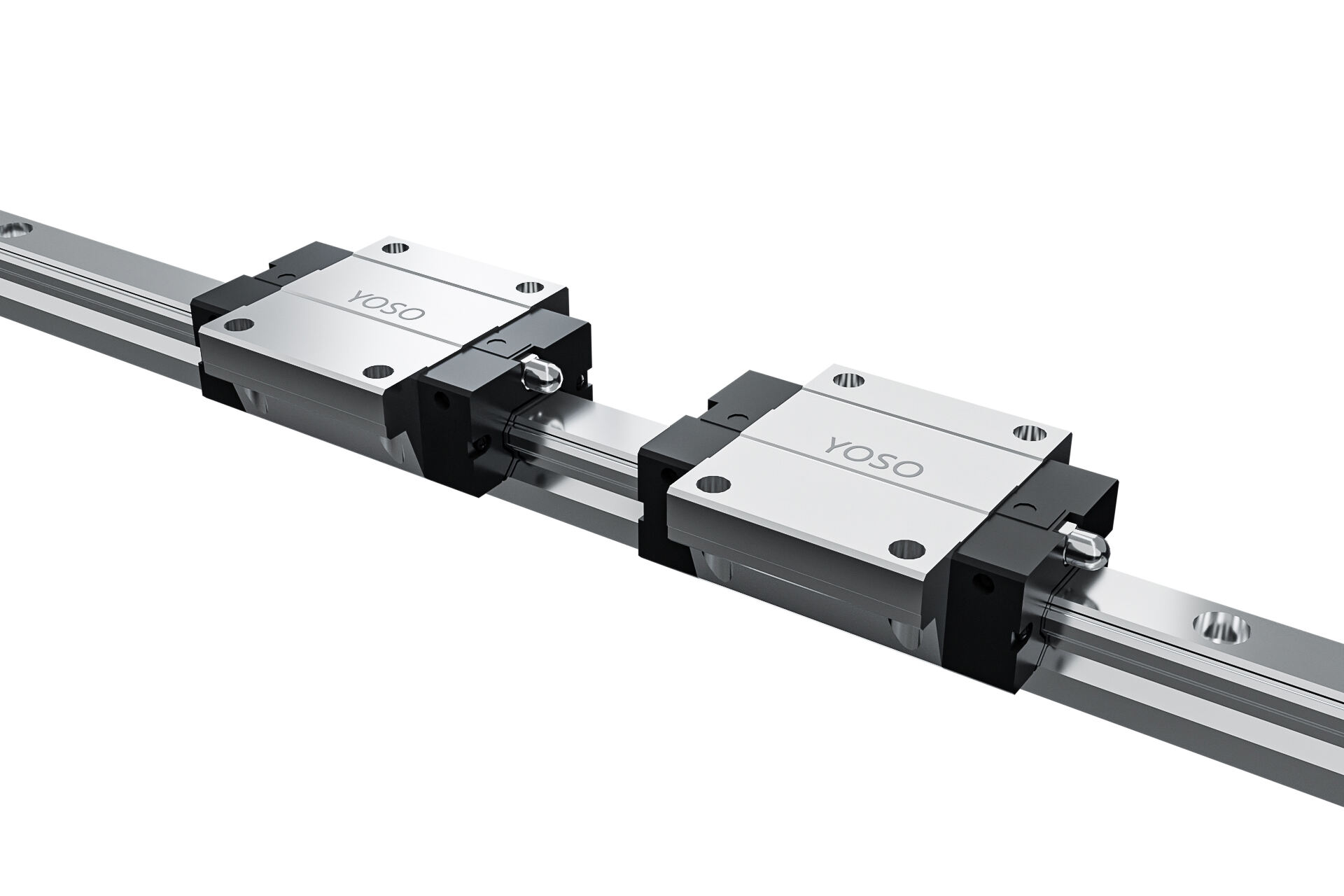

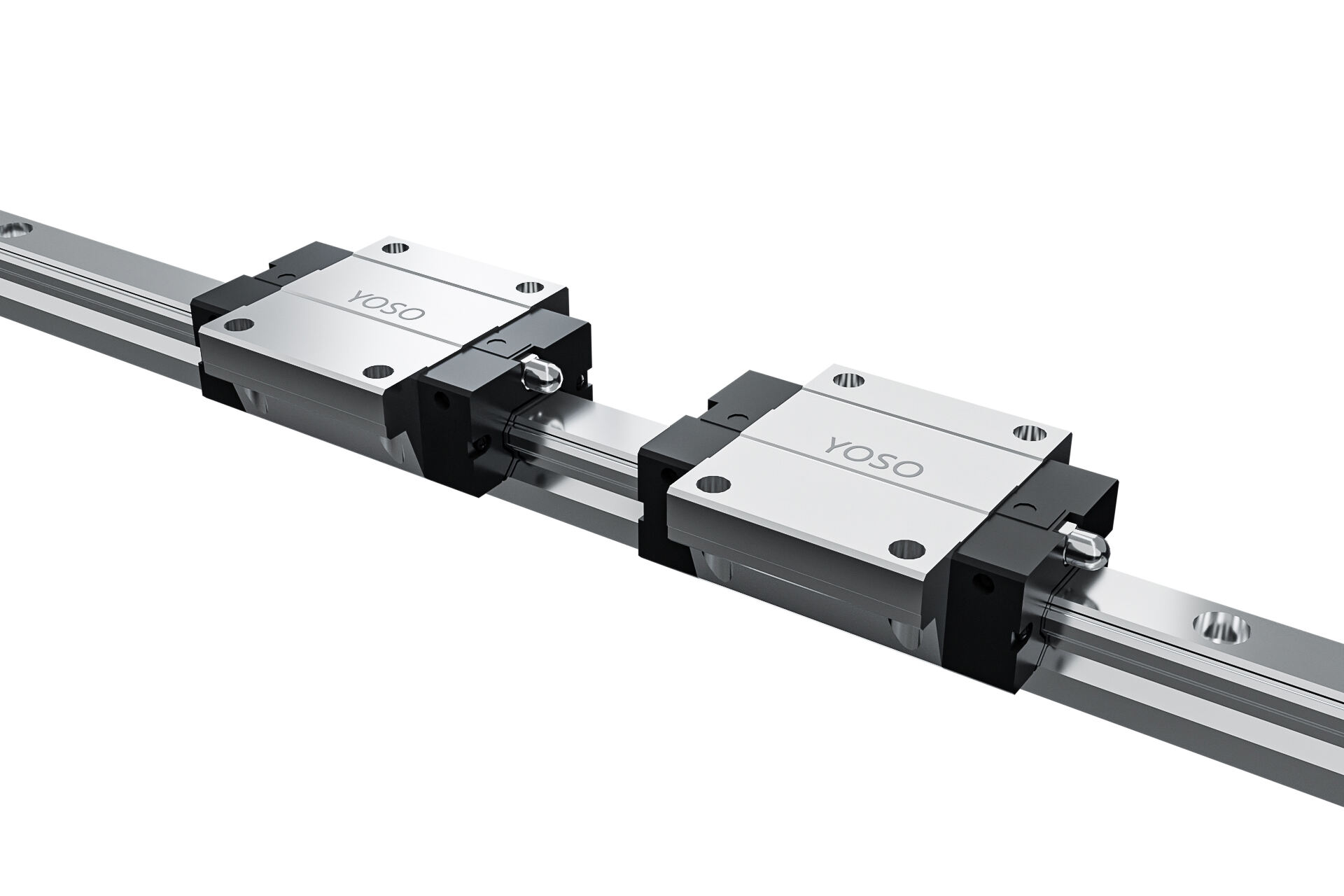

Thanh dẫn hướng tuyến tính , ngược lại, là các cặp động học "ma sát lăn", bao gồm các thành phần chính như thanh trượt, con trượt, bi thép và bộ đổi hướng. Trong quá trình vận hành, các viên bi thép bên trong con trượt lăn giữa các rãnh lăn của thanh trượt và con trượt, đạt được chuyển động vòng qua bộ đổi hướng. Thiết kế "thay thế ma sát trượt bằng ma sát lăn" này về cơ bản thay đổi cơ chế ma sát và mang lại bước nhảy về chất lượng trong hiệu suất. Các sản phẩm bán chạy nổi tiếng của YOSO MOTION, như thanh dẫn hướng tròn SBR12 và thanh dẫn hướng vi mô MGN, đều thuộc nhóm thanh dẫn hướng tuyến tính.

Hướng Dẫn Trượt thuộc về các cặp động học "tiếp xúc bề mặt". Cấu trúc của chúng thường bao gồm một thanh dẫn cố định (ray trượt) và một thanh dẫn chuyển động (khối trượt), chuyển động tịnh tiến được thực hiện thông qua sự trượt trực tiếp giữa các bề mặt tiếp xúc của hai bộ phận này. Để giảm ma sát, dầu bôi trơn được bôi lên các bề mặt tiếp xúc, và một số mẫu cao cấp được trang bị rãnh dầu để lưu trữ dầu. Cấu trúc này là loại truyền thống nhất của thanh dẫn và đã được sử dụng rộng rãi kể từ những ngày đầu của ngành công nghiệp chế tạo máy móc.

Thiết kế ma sát lăn này giúp giảm hao phí năng lượng và duy trì độ chính xác chuyển động ổn định — lý do vì sao các thanh dẫn tuyến tính rất quan trọng trong tự động hóa độ chính xác cao. Các dòng sản phẩm SBR và YGH của YOSO MOTION đã giành được sự công nhận toàn cầu nhờ ứng dụng công nghệ này, với hiệu suất đã được chứng minh tại các cơ sở điện tử và ô tô.

2. Khả năng chịu tải: Mỗi loại đều có ưu điểm riêng, phù hợp với các tình huống khác nhau

Mỗi loại thanh trượt phát huy tốt trong các tình huống chịu tải cụ thể. Tiếp xúc bề mặt của thanh trượt trượt giúp xử lý tải trọng tĩnh lớn/va đập (ví dụ: giường máy công cụ nặng) bằng cách phân bổ lực đều—thanh trượt bi có nguy cơ bị nứt bi thép tại những vị trí này.

Thanh trượt YOSO SBR

Việc phân chia tải trọng này đảm bảo độ tin cậy. Một khách hàng khai thác mỏ đã sử dụng thanh trượt trượt cho tải trọng tĩnh băng tải 10 tấn; các khách hàng tự động hóa logistics lại ưa chuộng thanh trượt bi để xử lý tải trọng động một cách êm ái (pallet, cánh tay robot).

Thanh trượt bi vượt trội trong việc chịu tải trọng động/hướng kính, với các viên bi thép phân bổ trọng lượng dọc theo các rãnh lăn. Tránh va chạm mạnh (nguy cơ bi bị nứt). Sử dụng thanh trượt bi cho các ứng dụng tải trung bình-nhẹ, tần suất cao; dùng thanh trượt trượt cho các công việc nặng, tốc độ thấp.

3. Chi phí Bảo trì: Thanh trượt Bi Ít Đáng Lo Hơn

Thanh trượt trượt dễ mài mòn cao, đòi hỏi phải tra dầu và vệ sinh hàng tháng (đặc biệt quan trọng trong các xưởng có nhiều phoi). Việc bỏ qua bảo trì có thể gây kẹt trục, dẫn đến mất cả ca sản xuất do ngừng máy.

Ma sát lăn của các thanh trượt tuyến tính giảm thiểu mài mòn. Thiết kế kín, tự bôi trơn của YOSO MOTION chống lại bụi (đã được chứng minh trong các xưởng PCB) với chu kỳ bảo trì từ 6-12 tháng—việc tiết kiệm thời gian ngừng máy lý giải việc sử dụng chúng trong các dây chuyền hoạt động 24/7.

4. Mức độ Khó Lắp đặt: Thanh trượt Tuyến tính Dễ dàng hơn cho Việc Lắp đặt Tiêu chuẩn

Các thanh trượt trượt cần phải được cạo chính xác tại chỗ để đảm bảo bề mặt tiếp xúc phẳng — công việc này mất vài ngày và đòi hỏi thợ chuyên môn. Việc lắp ráp không chính xác sẽ gây mài mòn nhanh và mất độ chính xác; không phù hợp với nhân viên mới.

Thiết kế mô-đun của thanh trượt tuyến tính giúp đơn giản hóa việc lắp đặt: căn chỉnh ray, bắt bu-lông — không cần gia công chính xác tại chỗ. Nhân viên thực tập có thể nắm bắt trong một giờ. Chính sự dễ dàng này đã thúc đẩy độ phổ biến của YOSO MOTION.

Hướng dẫn Lựa chọn: 3 Bước để Xác định Thanh trượt Phù hợp với Bạn

Việc lựa chọn thanh trượt phù hợp tuân theo ba bước thực tế:

YOSO MOTION: Việc Lựa chọn Thanh trượt Là Một Bản Thu nhỏ của Quá trình Nâng cấp Công nghiệp

Sự lựa chọn hướng dẫn phản ánh xu hướng chuyển dịch sang tự động hóa chính xác trong sản xuất. Các thanh trượt tuyến tính đang thống trị xu hướng này—YOSO MOTION chiếm gần 70% danh sách bán chạy nhất trên Alibaba nhờ cung cấp hiệu suất sẵn sàng sử dụng tại xưởng.

Không có loại thanh trượt nào là "tốt hơn"—chỉ có sự phù hợp đúng đắn. Phân tích này giúp đơn giản hóa việc lựa chọn. Hãy bình luận với các mẫu cụ thể hoặc ứng dụng để nhận được lời khuyên cá nhân hóa.

B{Làm rõ các yêu cầu cốt lõi}\n B -->|Chuyển động chính xác cao/Tần số cao/Bảo trì thấp| C[Ưu tiên thanh dẫn hướng tuyến tính]\n B -->|Thiết bị đơn giản/Tải trọng nặng/Tốc độ thấp/Ngân sách hạn chế| D[Ưu tiên thanh dẫn hướng trượt]\n C --> E{Phù hợp với các tình huống ứng dụng}\n D --> E\n E -->|Gia công chính xác/Điện tử/Robot| F[Xác nhận thanh dẫn hướng tuyến tính]\n E -->|Máy công cụ hạng nặng/Thiết bị thủ công| G[Xác nhận thanh dẫn hướng trượt]\n F --> H{Tính tổng chi phí sở hữu}\n G --> H\n H -->|Hoạt động dài hạn/Tự động hóa cao| I[Lựa chọn cuối cùng: Thanh dẫn hướng tuyến tính]\n H -->|Sử dụng ngắn hạn/Dự án một lần| J[Lựa chọn cuối cùng: Thanh dẫn hướng trượt]\n I --> K[Đã hoàn tất lựa chọn]\n J --> K","theme":"default","view":"chart"}},"DC2vfHL4KdRHOlcvrtocuDFVnrf":{"id":"DC2vfHL4KdRHOlcvrtocuDFVnrf","snapshot":{"align":"","author":"3710198389154762","children":["MacbfaYs9dkhp0cqKOGcwY1qnSh","WKnYfULajduRJHcUoHtc1ormnBh","NZYHf3BAcdoXonctaBIcHkIanoy", "OMSZfXeHhd15JLcIzT4cgQElnkf","FE5sf7a9ydJOmjcEkvtcIZvMn2H","JJe0fDKBXdLBWpclH0ecNwNDnLb","KLf0flTwidAzMucJfpUcqTEFnmc","WIVKfjuLudyYIVcKv9YcNnZKnKb","SR9ffi9yxdrve2cupgXcxf7pnzh","EHkTfSVWmdjZeycvY4rc6odNnpf","SFuFf1ro8dZbktclz7pcfK5Znsf","OfHqfd5U4dgqJYcD OvLccnffnSg","FZljfZCxUdRQP7ctLgUcJuf1nNS","OWR7f0zTDdEkUocXGOIcw7cWnZe","VkAmfqr95d55chcuvebc97onnUd","EmlqfrYWQdCHqBcpnYucQyAFntd","Uip9fYJ2od4qtpcLSzJc0O9ynxc","CRWEfwc4LdPC9HcGcMic4b80nse","Q7zOfzHrGdp2Rjc5Ia5cY5lhnMf","Xmv0f7Setdwruhcl2yncq09VnMe","ZA5 KfeyeBdo7QUcGQCtcax2bnwf","Q25vf1gaGdD79CcKKUAcojwYnxg","VGtRfDISWdSqCqcN9I3cySZknqf","Bw4SfdZbHdRZbOcjLUIcSzKUn9b","XIrMfZuIddMbrTcvu83c9uNYn7b","SIuKfN0c4dfHSycRCqscl3wZnrc","IGmOfuCT3dvDyLc9gYwcJ8O4n1g","LwuBfMnDkdq7xdcXqbQcJqh5nAb","M9dZfFFThdZwjwcGO4Sc fVX8nac","UQ33f4mRfdJisScC8frcDLMknYe","S3i4fcQ8md0KCyc2KZ7c0twzn3f","EVeofzMrZdeXd1cmamic1VVOnle","Bb20fQx2Xd7h5IcF30ucXdLJnFo","ICkYfdKTWdnsKicEOlvcGKTlnWu","YPvCf30DTdbBDBctd2cclUcXnQb","KDMkf7pWzdWaPycBEYfcuYNhnud","NuaJf44lldo7HpcUxEfcwVFCn9f","MNMFfeC vLdUdkHcl5lJcW9FFnue","TTxrf9cqtdFZQ7cmueNcYCkWnHg","NynDfTYtPdSMP9cgMOkc9qLPnSe","GOWEfdzS2d5GTucHwrzcPEiBnFh","Ycdufx6H5dNlKgcWboacRdDjnPb","IHZUf4x3GdLTsJc2cZXcH5JxnEc"],"comment_container_id":"JgBXfu3R4dyGZAcjDnlcgotTnId","comments":[],"doc_info":{"dele ted_editors":null,"editors":["3710198389154762"],"option_modified":null,"options":["editors","create_time","edit_time"]},"hidden":false,"locked":false,"parent_id":"","revision_container_id":"ReS9fMTOEd7tMwcwJ2NcJRRwnRb","revisions":[],"status":{"streaming": {"enabled":false,"expired_at":"1763367228","source":1,"operator_id":"3710198389154762"}},"text":{"apool":{"numToAttrib":{"0":["author","3710198389154762"]},"nextNum":1,"attribToNum":{"author,3710198389154762":0}},"initialAttributedTexts":{"text":{"0":"Thanh dẫn hướng tuyến tính so với thanh dẫn hướng trượt: Sự khác biệt cốt lõi và lựa chọn Hướng dẫn"},"attribs":{"0":"*0+1v"},"rows":{},"cols":{}}},"type":"page"}}},"payloadMap":{},"extra":{"channel":"saas","pasteRandomId":"32903089-f853-4d31-9a39-0d49e0fc81d5","mention_page_title":{ },"external_mention_url":{}},"isKeepQuoteContainer":false,"selection":[{"id":54,"type":"block","recordId":"NuaJf44lldo7HpcUxEfcwVFCn9f"}],"pasteFlag":"aa98c37a-1174-4728-be27-dd0ce9c5087d"}">

B{Làm rõ các yêu cầu cốt lõi}\n B -->|Chuyển động chính xác cao/Tần số cao/Bảo trì thấp| C[Ưu tiên thanh dẫn hướng tuyến tính]\n B -->|Thiết bị đơn giản/Tải trọng nặng/Tốc độ thấp/Ngân sách hạn chế| D[Ưu tiên thanh dẫn hướng trượt]\n C --> E{Phù hợp với các tình huống ứng dụng}\n D --> E\n E -->|Gia công chính xác/Điện tử/Robot| F[Xác nhận thanh dẫn hướng tuyến tính]\n E -->|Máy công cụ hạng nặng/Thiết bị thủ công| G[Xác nhận thanh dẫn hướng trượt]\n F --> H{Tính tổng chi phí sở hữu}\n G --> H\n H -->|Hoạt động dài hạn/Tự động hóa cao| I[Lựa chọn cuối cùng: Thanh dẫn hướng tuyến tính]\n H -->|Sử dụng ngắn hạn/Dự án một lần| J[Lựa chọn cuối cùng: Thanh dẫn hướng trượt]\n I --> K[Đã hoàn tất lựa chọn]\n J --> K","theme":"default","view":"chart"}},"DC2vfHL4KdRHOlcvrtocuDFVnrf":{"id":"DC2vfHL4KdRHOlcvrtocuDFVnrf","snapshot":{"align":"","author":"3710198389154762","children":["MacbfaYs9dkhp0cqKOGcwY1qnSh","WKnYfULajduRJHcUoHtc1ormnBh","NZYHf3BAcdoXonctaBIcHkIanoy", "OMSZfXeHhd15JLcIzT4cgQElnkf","FE5sf7a9ydJOmjcEkvtcIZvMn2H","JJe0fDKBXdLBWpclH0ecNwNDnLb","KLf0flTwidAzMucJfpUcqTEFnmc","WIVKfjuLudyYIVcKv9YcNnZKnKb","SR9ffi9yxdrve2cupgXcxf7pnzh","EHkTfSVWmdjZeycvY4rc6odNnpf","SFuFf1ro8dZbktclz7pcfK5Znsf","OfHqfd5U4dgqJYcD OvLccnffnSg","FZljfZCxUdRQP7ctLgUcJuf1nNS","OWR7f0zTDdEkUocXGOIcw7cWnZe","VkAmfqr95d55chcuvebc97onnUd","EmlqfrYWQdCHqBcpnYucQyAFntd","Uip9fYJ2od4qtpcLSzJc0O9ynxc","CRWEfwc4LdPC9HcGcMic4b80nse","Q7zOfzHrGdp2Rjc5Ia5cY5lhnMf","Xmv0f7Setdwruhcl2yncq09VnMe","ZA5 KfeyeBdo7QUcGQCtcax2bnwf","Q25vf1gaGdD79CcKKUAcojwYnxg","VGtRfDISWdSqCqcN9I3cySZknqf","Bw4SfdZbHdRZbOcjLUIcSzKUn9b","XIrMfZuIddMbrTcvu83c9uNYn7b","SIuKfN0c4dfHSycRCqscl3wZnrc","IGmOfuCT3dvDyLc9gYwcJ8O4n1g","LwuBfMnDkdq7xdcXqbQcJqh5nAb","M9dZfFFThdZwjwcGO4Sc fVX8nac","UQ33f4mRfdJisScC8frcDLMknYe","S3i4fcQ8md0KCyc2KZ7c0twzn3f","EVeofzMrZdeXd1cmamic1VVOnle","Bb20fQx2Xd7h5IcF30ucXdLJnFo","ICkYfdKTWdnsKicEOlvcGKTlnWu","YPvCf30DTdbBDBctd2cclUcXnQb","KDMkf7pWzdWaPycBEYfcuYNhnud","NuaJf44lldo7HpcUxEfcwVFCn9f","MNMFfeC vLdUdkHcl5lJcW9FFnue","TTxrf9cqtdFZQ7cmueNcYCkWnHg","NynDfTYtPdSMP9cgMOkc9qLPnSe","GOWEfdzS2d5GTucHwrzcPEiBnFh","Ycdufx6H5dNlKgcWboacRdDjnPb","IHZUf4x3GdLTsJc2cZXcH5JxnEc"],"comment_container_id":"JgBXfu3R4dyGZAcjDnlcgotTnId","comments":[],"doc_info":{"dele ted_editors":null,"editors":["3710198389154762"],"option_modified":null,"options":["editors","create_time","edit_time"]},"hidden":false,"locked":false,"parent_id":"","revision_container_id":"ReS9fMTOEd7tMwcwJ2NcJRRwnRb","revisions":[],"status":{"streaming": {"enabled":false,"expired_at":"1763367228","source":1,"operator_id":"3710198389154762"}},"text":{"apool":{"numToAttrib":{"0":["author","3710198389154762"]},"nextNum":1,"attribToNum":{"author,3710198389154762":0}},"initialAttributedTexts":{"text":{"0":"Thanh dẫn hướng tuyến tính so với thanh dẫn hướng trượt: Sự khác biệt cốt lõi và lựa chọn Hướng dẫn"},"attribs":{"0":"*0+1v"},"rows":{},"cols":{}}},"type":"page"}}},"payloadMap":{},"extra":{"channel":"saas","pasteRandomId":"8134ad9d-2d0a-4c6a-bfdf-76f4fb4939ee","mention_page_title":{},"external_mention_url":{}},"isKeepQuoteContainer":false,"selection":[{"id":54,"type":"block","recordId":"NuaJf44lldo7HpcUxEfcwVFCn9f"}],"pasteFlag":"aa98c37a-1174-4728-be27-dd0ce9c5087d"}">

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ