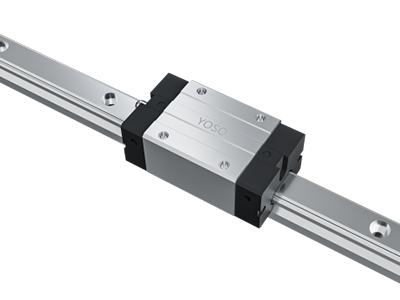

Linjära led (även kända som linjära glidbanor eller linjära banor) är precisionsöverföringskomponenter som används i automationsutrustning, maskinverktyg, halvledarutrustning och medicinska instrument. Deras kärnfunktion är att erbjuda jämn, låg friktions linjär rörelse samtidigt som hög precision och styvhet bibehålls under tunga belastningar. Jämfört med traditionella glidleder kan linjära led avsevärt förbättra positioneringsnoggrannheten, driftseffektiviteten och livslängden på mekanisk utrustning.

Typer av linjära led

Klassificering efter rullande element

Kul typ linjära led: Låg friktion, hög hastighet, lämpliga för höghastighets- och högprecisionsapplikationer.

Rulltyps linjära guider: Stort kontaktområde, hög styvhet, lämpliga för tunga belastningar och maskinverktyg med hög styvhet.

Klassificering efter glidlådans form

Flänsade glidlådor: Har en monteringsfläns för säker installation och är lämpliga för flerriktade belastningar.

Fyrkantiga glidlådor: Utan fläns, kompakta och lämpliga för utrustning med begränsat installationsutrymme.

Låga glidlådor: Erbjuder låg höjd, låg tyngdpunkt och stabil drift, ofta använda i utrustning med strikta krav på utrymme.

Höga glidlådor: Dessa är högre, med monteringsyta längre från grundplattan på guiden, vilket förhindrar interferens med underliggande strukturer samtidigt som de ger större vridstyvhet.

Förlängda glidlådor: Dessa glidlådor är förlängda, vilket ökar kontaktområdet och förbättrar styvhet och lastkapacitet.

Specialglidlådor: Dessa är utformade för specifika miljöer, såsom dammtäta, högtemperatur- och miniatyrmodeller.

Världens främsta märken för linjära guider

| Varumärke | Country/Region | Representativa serier | Huvudfunktioner |

| THK | Japan | HSR, SHS, SSR | Uppfinnare av linjära guider, komplett produktsortiment, hög precision och styvhet |

| NSK | Japan | LH, RA | Hög precision, utmärkt prestanda vid hög hastighet |

| Ikon | Japan | LWH, LWLF | Kompakt design, lämplig för lätt belastning och precisionsutrustning |

| HIWIN | TAIWAN | HG, EG, QH, RG | Konkurrenskraftiga priser, brett modelltäckning, hög marknadsandel |

| PMI | TAIWAN | MSB, MSA | Mellanhög till hög positionering, allmänt använd inom verktygsmaskiner och automation |

| SCHNEEBERGER | Schweiz | MONORAIL MR | Hög precision, används inom halvledar- och medicindustri |

| Bosch Rexroth | Tyskland | R serie | Stark lastkapacitet, hög marknadsandel i Europa |

| Ina | Tyskland | KWVE, KUVE | Del av Schaeffler Group, hög precision, lämplig för avancerad utrustning |

Som en kärnkomponent i precisionsmaskiner spelar linjära guider en viktig roll inom många industriella tillämpningar. Varje större märke erbjuder fördelar vad gäller noggrannhet, styvhet och kostnadseffektivitet, beroende på användningskraven. När man väljer en modell kan användaren överväga utrustningens belastning, noggrannhet och budget för att välja det mest lämpliga märket och modellen.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ