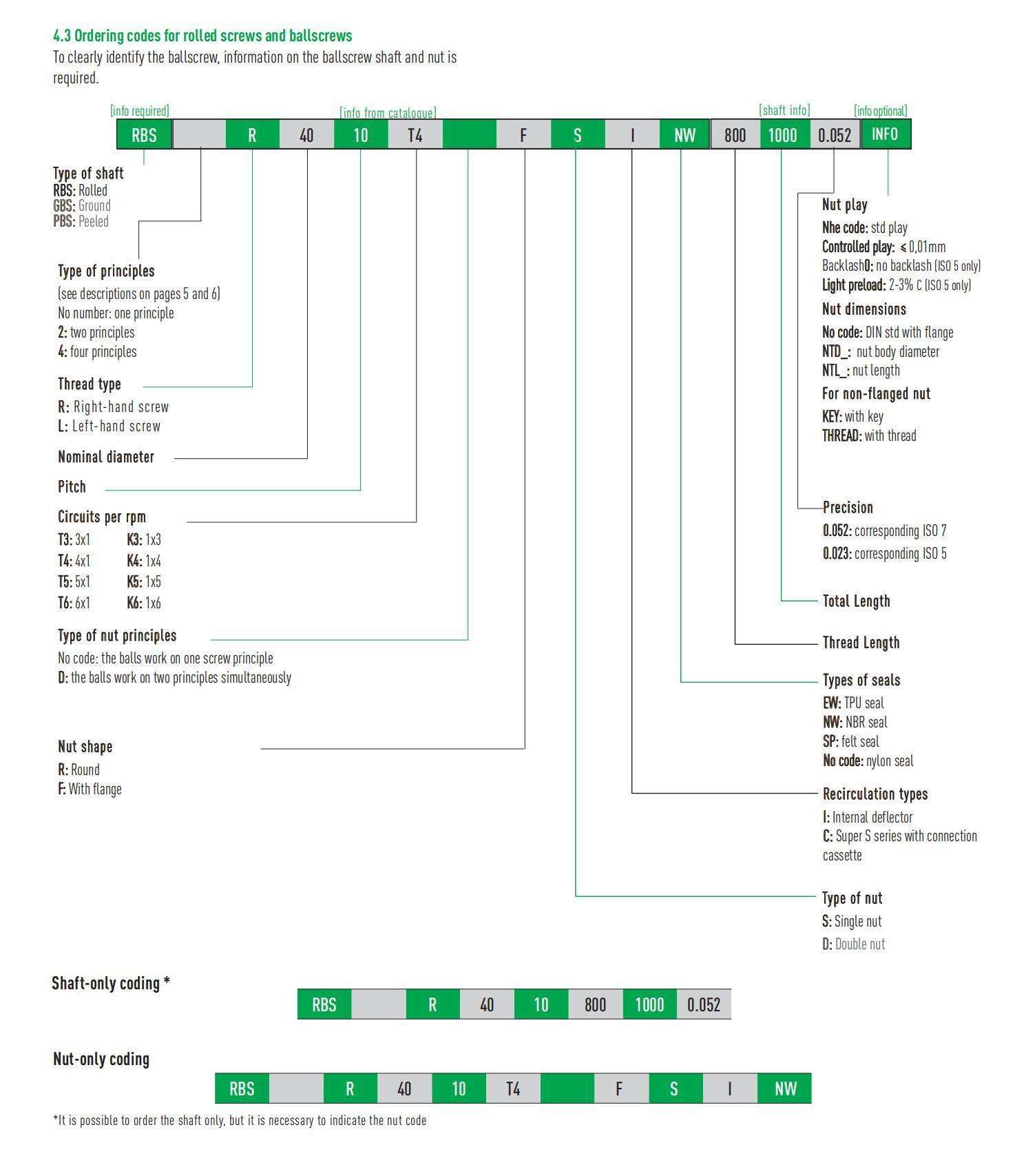

Significado do modelo:

“R”: Indica um fuso de esferas com rotação à direita.

“20”: Representa um diâmetro nominal de 20mm.

“10”: Refere-se a um passo de 10 mm, o que significa que a porca se move 10 mm ao longo do eixo do parafuso a cada rotação do parafuso.

“T3”: 3×1

“FSI”: “F”: Porca com flange, “S”: Porca simples e “I”: Recirculação interna.

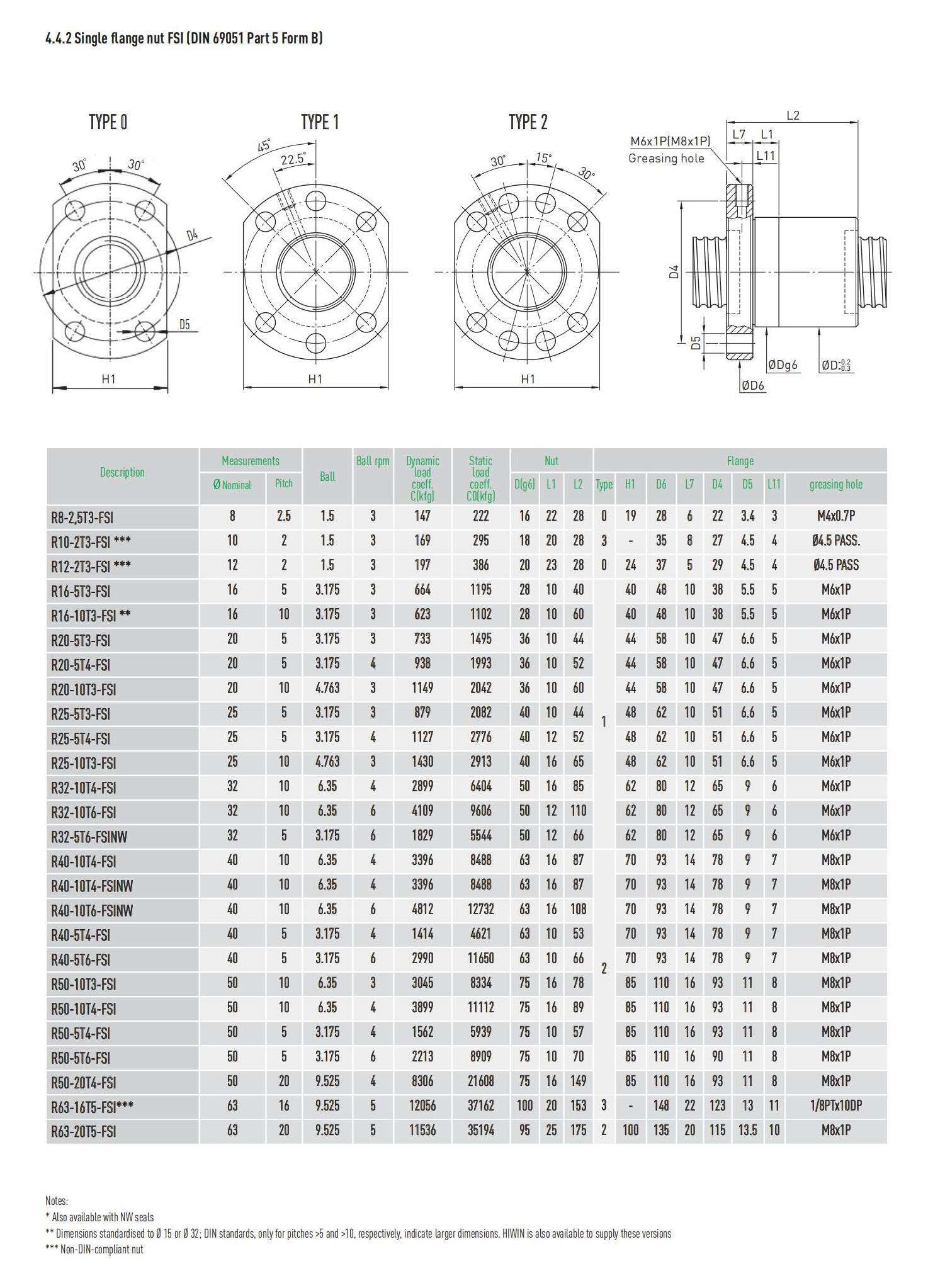

Comparando-se com os parafusos trapezoidais tradicionais de rosca deslizante, os parafusos de esferas HIWIN R20-10T3-FSI possuem maior eficiência na transmissão e menores perdas por atrito. Os parafusos tradicionais apresentam elevada perda de energia e geração de calor durante a transmissão alternada, e com o uso prolongado podem facilmente provocar redução na precisão. O FSI consegue rotação com contato através da transmissão por esferas, e seu coeficiente de atrito é muito inferior ao das roscas deslizantes, melhorando significativamente a eficiência da transmissão, que pode ultrapassar 90%. Essa característica não apenas reduz o consumo de energia, como também prolonga a vida útil e diminui o aumento de temperatura do sistema. Para equipamentos de automação que exigem economia de energia e estabilidade, os parafusos de esferas FSI podem substituir soluções com parafusos tradicionais, proporcionando resposta mais rápida, maior durabilidade e menor frequência de manutenção. Para projetos de modernização e reforma de equipamentos, o FSI é uma escolha ideal para melhorar o desempenho do sistema de transmissão.

Direitos Reservados © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd Todos os Direitos Reservados