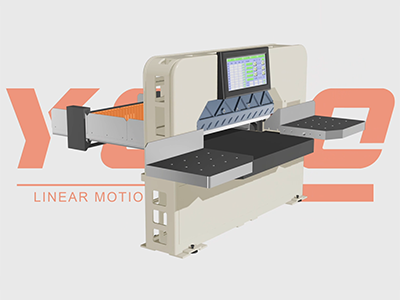

Som viktig etterbehandlingsutstyr i trykk-, emballasje- og papirindustrien bestemmer papirknivers kutterpresisjon og stabilitet direkte produktkvalitet og produksjonseffektivitet. Prestasjonsforbedringen i moderne papirkniver skyldes i stor grad den omfattende bruken av disse to presisjonsmekaniske komponentene: kulespindel og lineær føring.

I. Kulespindel: Kjernen i presisjonsposisjonering

Et kulespindelpar er en presisjonsenhet som konverterer rotasjonsbevegelse til lineær bevegelse. Dets kjernefordeler ligger i høy presisjon, høy effektivitet og lav friksjon.

1. Hovedfunksjoner i papirknivmaskiner:

Styring av papirstøtteren (bakre måleskive): Dette er dens mest grunnleggende anvendelse. En servomotor driver kulespindelen, som kontrollerer papirstøtterens nøyaktige lineære bevegelse langs X-aksen, og skyver papirstapelen som skal skjæres, nøyaktig til den forhåndsinnstilte skjæreposisjonen.

2. Kjerne-teknologier og fordeler:

Høy overføringseffektivitet: På grunn av bruk av kulerullingsfriksjon kan overføringseffektiviteten nå over 90 %, langt over de 20–40 % som en glidespindel har. Dette resulterer i raskere systemrespons, lavere energitap og muligheten til å bruke en mindre driveenhet.

Høy posisjoneringsnøyaktighet og gjentakbarhet: Presisjons-slepet spindel og forspenningsmekanisme uten slakk kontrollerer effektivt overføringsluft og oppnår mikronivåets posisjoneringsnøyaktighet. Dette er avgjørende for å sikre konsekvente skjæremål mellom partier.

Høy aksial stivhet: I stand til å tåle de betydelige aksiale lastene som oppstår under papirføring, og sikrer posisjonsstabilitet og dynamisk responshastighet under tunge belastninger.

II. Lineærveiledere: Grunnlaget for bevegelsespresisjon

Lineærveiledere gir høy-stive og høy-presisjons lineær veiledning for bevegelige deler, og tåler laster og momenter fra alle retninger.

1. Hovedfunksjoner i papirknivmaskiner:

Veiledning av papirføreren: Sikrer at papirføreren, drevet av kulospindelen, beveger seg langs en strengt lineær bane uten sidewardrift eller vridning.

Støtte og veiledning av skjærebladet: I høytytende papperskjærere støttes det tunge skjærebladet av høyfasthets lineærveiledere, noe som sikrer en jevn og nøyaktig vertikal nedgang, og forhindrer ujevne skjæreflater eller verktøy slitasje forårsaket av bladvinkel.

2. Kjerne-teknologier og fordeler:

Ekstremt høy presisjon i bevegelsesveiledning: Føringsrails er presisjonsjslepet for eksepsjonell rettlinjethet og parallelitet, og gir en pålitelig referanse for hele bevegelsessystemet.

Utmerket lastekapasitet og stivhet: Designet med flere rader kulegjennomløp kan samtidig tåle radiell, omvendt radiell og lateral belastning, samt væskemomenter, noe som effektivt motvirker skjærechock og sikrer langvarig maskinstabilitet.

Langsiktig nøyaktighetsbeholdning: De slitesterke egenskapene til rullefriksjon gjør at lineærledere kan beholde opprinnelig monteringsnøyaktighet over tid i høyhastighets- og høyfrekvente driftsmiljøer, noe som betydelig forlenger intervallene mellom utstyrsoverhalinger.

III. Systemsynergi: Bygging av en høytytende lineær bevegelsesenhet

I en papperskjærer opererer kulespindelen og lineærlederen ikke uavhengig; de danner snarere en komplett presisjonslineær bevegelsesmodul.

Arbeidsdeling og samarbeid: Kulespindelen, som transmisjonsleddet, leverer kraft og kontrollerer forskyvning; lineærlederen, som ledende ledd, begrenser bevegelsesbanen og bærer moment.

Yteevne superponering: Kombinasjonen av de to muliggjør nøyaktig kontroll av både kraft og posisjon. Kullespindelen sørger for at papirtrykkeren flyttes på plass, mens lineærveivledningen sørger for at den beveger seg rett fram. Denne synergien sikrer høy hastighet, høy presisjon, høy dynamisk respons og lang levetid for papirkutteren.

Med års teknologisk erfaring og en dyp forståelse av markedets behov, brukes våre kullespindler, lineærveivledninger og andre overføringssystemkomponenter mye i flere felt, og hjelper kunder med å forbedre produksjonseffektivitet og produktkvalitet.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ