Planetary screws are the gold standard for high-precision, heavy-load linear motion systems, widely used in aerospace, robotics, and machine tools. As engineers search for “planetary screw selection guide,” “how to extend planetary screw service life,” and “planetary vs ball screw differences,” understanding the key specifications, optimization strategies, and common issues is essential. This blog addresses the most searched questions about planetary screws, providing actionable insights to help you choose the right component, maximize performance, and minimize downtime—all tailored to meet industrial automation demands and boost Google search visibility.

What Are Planetary Screws? Key Advantages Over Alternatives

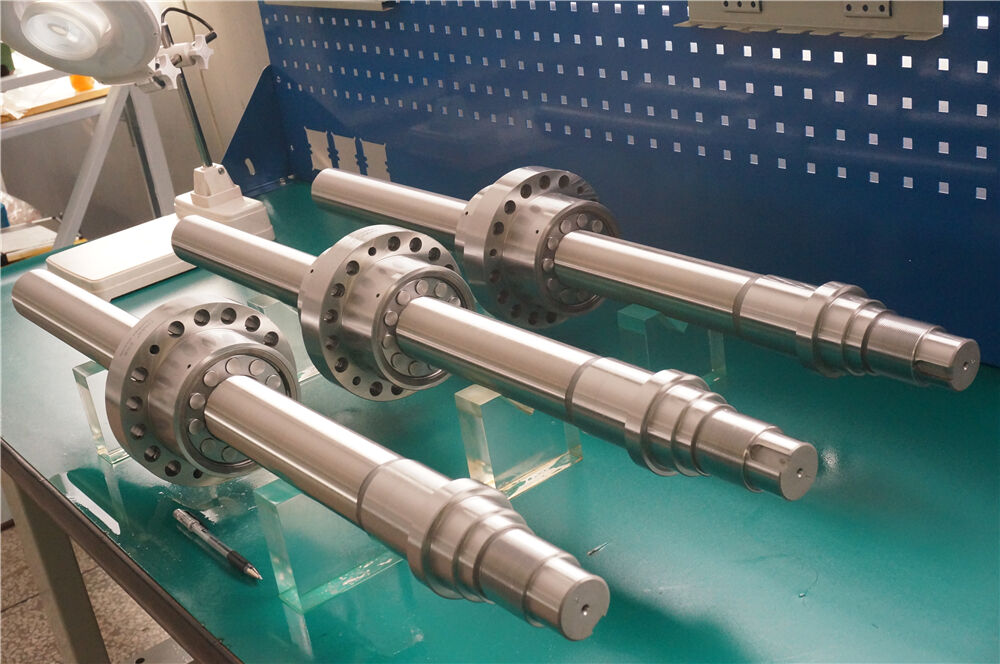

Planetary screws (also called planetary roller screws) use a unique design with satellite rollers that mesh with the screw shaft and nut, delivering superior load capacity and precision compared to ball screws and lead screws. This design enables line contact between components, a critical difference from the point contact of ball screws.

Core advantages that drive their adoption—aligning with search queries like “planetary screw benefits”:

-

High Load Capacity: 2-3x the load-bearing capability of ball screws of the same size, ideal for heavy-duty applications.

-

Micron-Level Precision: Zero-backlash designs with ±0.001mm to ±0.005mm positioning accuracy, suited for ultra-precision tasks.

-

Long Service Life: Even load distribution reduces wear, extending lifespan by 2-4x compared to ball screws.

-

Energy Efficiency: Electromechanical design with over 85% efficiency, outperforming hydraulic systems and ball screws.

For searches like “planetary vs ball screw,” the key distinction lies in load capacity and precision—planetary screws excel in heavy-load, high-precision scenarios, while ball screws are more cost-effective for light to medium loads.

Critical Factors for Planetary Screw Selection (Google Search Focus)

Selecting the right planetary screw requires aligning specifications with application needs. Below are the top factors, optimized for search queries like “planetary screw selection criteria”:

1. Load Capacity & Safety Factor

Calculate dynamic (operating), static (idle), and shock loads. Choose a planetary screw with a safety factor of 1.5-2.0 to account for unexpected load spikes. For heavy-load applications (e.g., presses, robotics), opt for roller-type designs with high dynamic load ratings.

2. Precision Grade & Backlash Control

Planetary screw precision grades (C1-C5) determine accuracy:

-

C1-C2 (±0.001mm-±0.002mm): Ultra-precision (aerospace, medical robotics).

-

C3-C4 (±0.003mm-±0.005mm): High precision (CNC machines, injection molding).

-

C5 (±0.01mm): General industrial use (automation lines).

Preloaded designs (double-nut, offset roller) eliminate backlash, critical for repeatable positioning in precision applications.

3. Environmental Compatibility

Harsh environments demand specialized planetary screw designs, addressing searches like “corrosion-resistant planetary screws”:

-

Dusty/wet settings: IP65+ sealed assemblies with scrapers to prevent debris ingress.

-

Corrosive environments: Stainless steel (AISI 440C) or nitride/PVD coatings.

-

Extreme temperatures: Heat-resistant alloys and lubricants rated for -50°C to 150°C.

4. Speed & Motion Profile

Planetary screws support feed rates up to 5m/s, but speed depends on load and lubrication. For high-speed, low-load tasks, choose designs with low friction; for heavy-load, slow-speed applications, prioritize rigidity.

How to Optimize Planetary Screw Performance & Service Life

Proper optimization extends lifespan and maintains precision, addressing searches like “planetary screw maintenance tips”:

1. Targeted Lubrication

Use application-specific lubricants: food-grade grease (NSF H1) for hygiene-sensitive industries, high-temperature synthetic grease for extreme heat, and anti-wear grease for heavy loads. Reapply every 500-1000 operating hours, or more frequently in dusty environments.

2. Precision Installation & Alignment

Ensure the mounting surface is flat (error ≤0.01mm/m) and aligned to avoid bending stress. Use laser alignment tools to position the screw shaft, preventing uneven load distribution and premature wear.

3. Predictive Maintenance

Monitor vibration, temperature, and noise to detect issues early. Abnormal vibration indicates misalignment or worn rollers, while increased temperature signals lubrication problems. Predictive maintenance reduces unplanned downtime by 30-40%.

Common Planetary Screw Issues & Troubleshooting

Addressing search queries like “planetary screw problems” and “why is my planetary screw noisy”:

1. Positioning Deviation

Causes: Loose mounting bolts, backlash, or contamination. Solutions: Retighten bolts with thread lockers, adjust preload, clean the raceway, and reapply lubricant.

2. Abnormal Noise

Causes: Insufficient lubrication, misalignment, or damaged rollers. Solutions: Replace degraded lubricant, realign the screw, and inspect/replace worn components.

3. Premature Wear

Causes: Overloading, poor alignment, or incompatible lubrication. Solutions: Reduce load (or upgrade to a higher-capacity model), realign the mounting surface, and use application-specific lubricant.

Planetary Screw Applications Across Industries

Aligning with searches like “planetary screws for aerospace” and “robotic planetary screws”:

-

Aerospace: Landing gear actuation, flight control systems (zero-backlash, high-temperature resistance).

-

Robotics: Heavy-duty robotic arms, precision actuation (high load capacity, repeatability).

-

Machine Tools: CNC machining centers, grinding machines (ultra-precision C1-C2 grades).

-

Medical: Surgical robots, patient positioning systems (stainless steel, sterile design).

-

Energy: Wind turbine pitch control, solar trackers (corrosion-resistant, low maintenance).

Conclusion: Choose & Maintain Planetary Screws for Peak Performance

Planetary screws are a critical investment in high-precision motion systems—their performance depends on proper selection, installation, and maintenance. By addressing key search pain points and following best practices, you can maximize their lifespan, ensure accuracy, and reduce operational costs.

If you’re unsure which planetary screw fits your application, or need help troubleshooting existing systems, our team of experts is here to assist. We offer standard and custom planetary screws engineered for durability and precision, tailored to your industry’s unique needs. Contact us today to discuss your project.

Table of Contents

- What Are Planetary Screws? Key Advantages Over Alternatives

- Critical Factors for Planetary Screw Selection (Google Search Focus)

- How to Optimize Planetary Screw Performance & Service Life

- Common Planetary Screw Issues & Troubleshooting

- Planetary Screw Applications Across Industries

- Conclusion: Choose & Maintain Planetary Screws for Peak Performance

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ