Le rotaie di scorrimento HIWIN CGL25CA sono ampiamente utilizzate in varie apparecchiature di automazione e CNC grazie alla loro elevata precisione e rigidità. Per garantire le prestazioni delle rotaie di scorrimento, il collegamento di installazione è cruciale. Prima di procedere all'installazione, assicurarsi innanzitutto che la superficie della base di installazione sia piana e priva di impurità, e pulirla accuratamente. Si consiglia di utilizzare una superficie di riferimento lavorata a grinding o scraping per garantire la rettilineità e il parallelismo dell'installazione della rotaia di scorrimento.

In secondo luogo, durante il processo di installazione, i binari guida e i carrelli devono evitare di essere premuti o colpiti con forza e devono essere lentamente allineati con i fori di montaggio; le viti devono essere serrate in modo uniforme seguendo un ordine sequenziale. Dopo l'installazione, si consiglia di effettuare un'adeguata regolazione della precarica e un test di movimentazione per verificare la presenza di eventuali inceppamenti o giochi eccessivi. Inoltre, l'utilizzo di grasso originale HIWIN e di accessori antipolvere può prolungare la vita del sistema e ridurre la frequenza di manutenzione.

Una corretta tecnica di installazione non solo garantisce le prestazioni e la precisione del binario guida CGL25CA, ma contribuisce anche a un funzionamento stabile a lungo termine dell'equipaggiamento, migliorando l'efficienza complessiva della produzione.

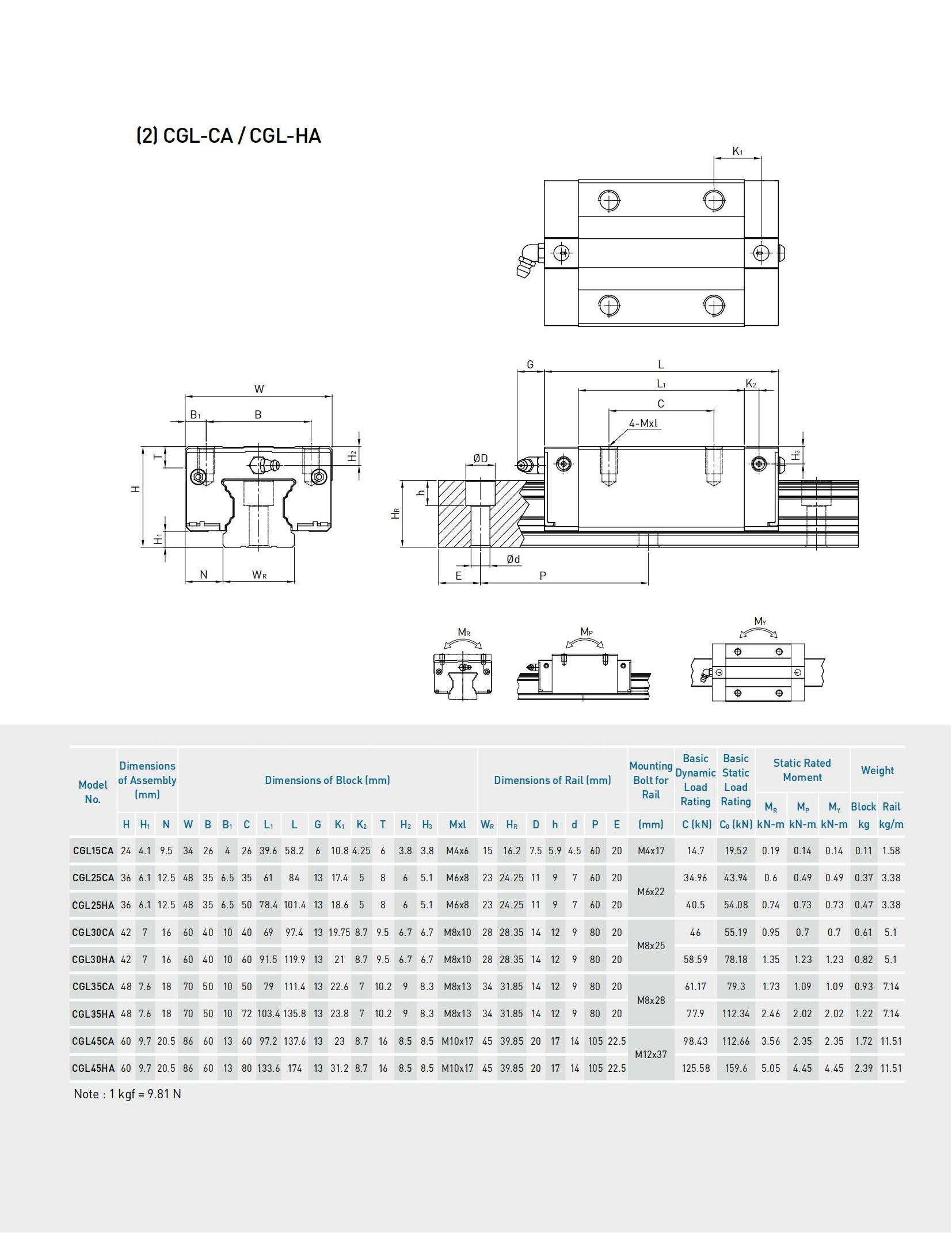

Informazioni sul prodotto | |

Nome del prodotto |

HIWIN CGL25CA Linear Guide |

Materiale |

Acciaio |

Lunghezza |

Lunghezza Personalizzata |

Modello NO. |

CGH15CA CGH2OCA CGH2OHA CGH25CA CGH25HA CGH30CA CGH3OHA CGH35CA CGH35HA CGH45CA CGH45HA |

I Nostri Servizi |

Secondo i disegni o le campionature per produrre articoli per i nostri clienti. |

Confezione del prodotto |

a. Sacchetto di plastica con scatola o contenitore in legno. Possiamo fornire le informazioni di spedizione al nostro cliente in qualsiasi momento. |

Scenari di applicazione tipici |

a. Macchine Utensili CNC ad Alta Precisione b. Attrezzature per la produzione di semiconduttori c. Robot Industriali d. Linee di Produzione Automatizzate e Sistemi di Movimentazione Materiali e. Apparecchiature mediche |

Blocco protezione polvere |

SS DD |

Precision |

C – Normale H – Alto P – Precisione SP – Super precisione UP – Ultra super precisione |

Copyright © Jingpeng Machinery&Equipment (Shanghai) Co., Ltd. Tutti i diritti riservati