Termék Információ | |

Termék neve |

THK BNFN10020A-7.5 Golyósorsó |

Anyag |

Gömbeszemüveg acél, keményítési acél, krom acél, rostmentes acél |

Pontosság |

C3 C5 C7 C10 |

Alkalmazás |

1.Gépgépek és megmunkáló központok

2.Félvezető gyártóberendezések

3.Ipari robotok

orvosi eszközök

5.Pontos mérő- és vizsgálati berendezések

6.Gyártóüzemek automatizálása és anyagmozgatás

|

Tulajdonságok |

a. Nagy sebesség b. Magas merevség c. Alacsony zaj d. Pontos köszörülés e. Pontos pozicionálás f. Dupla anya |

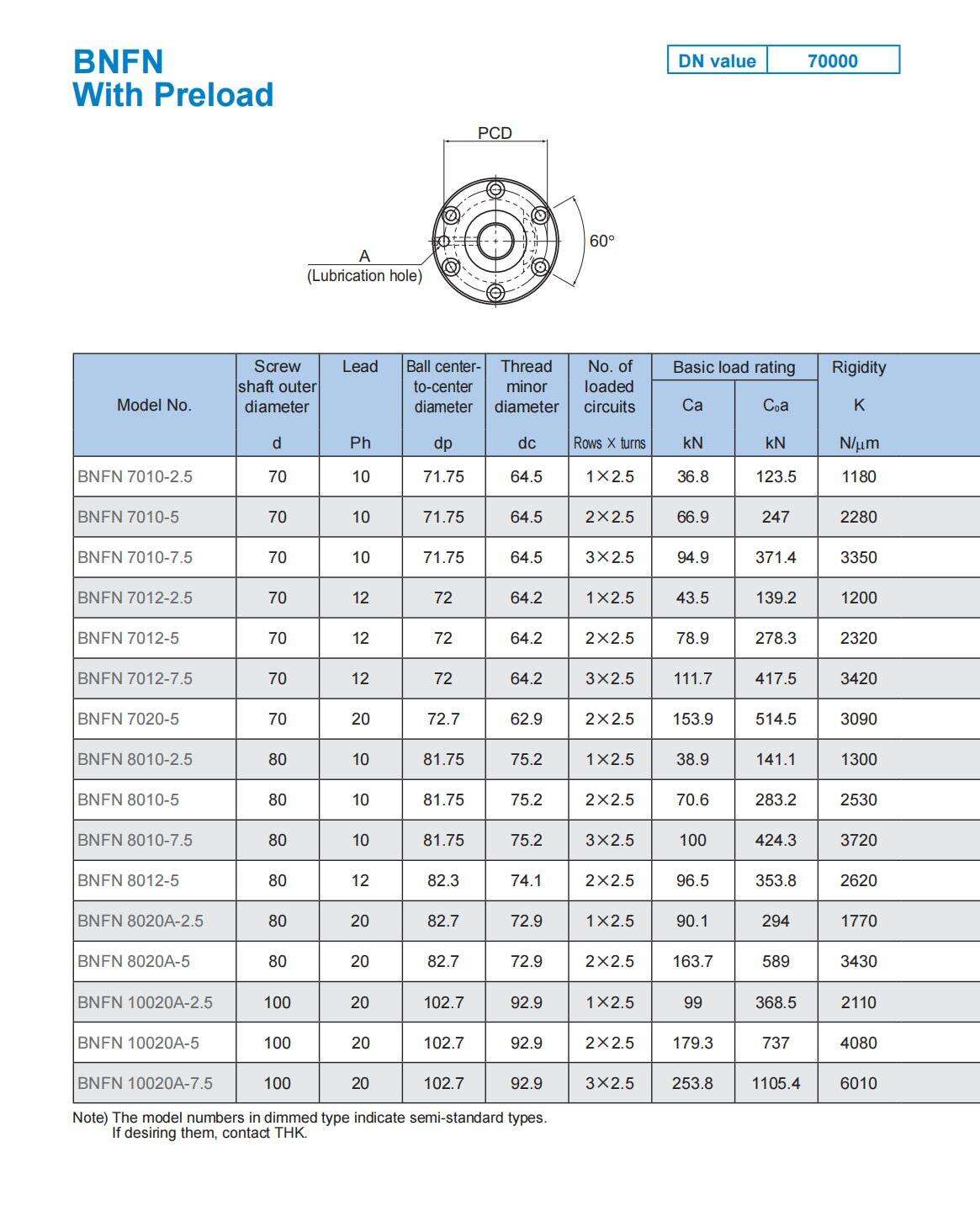

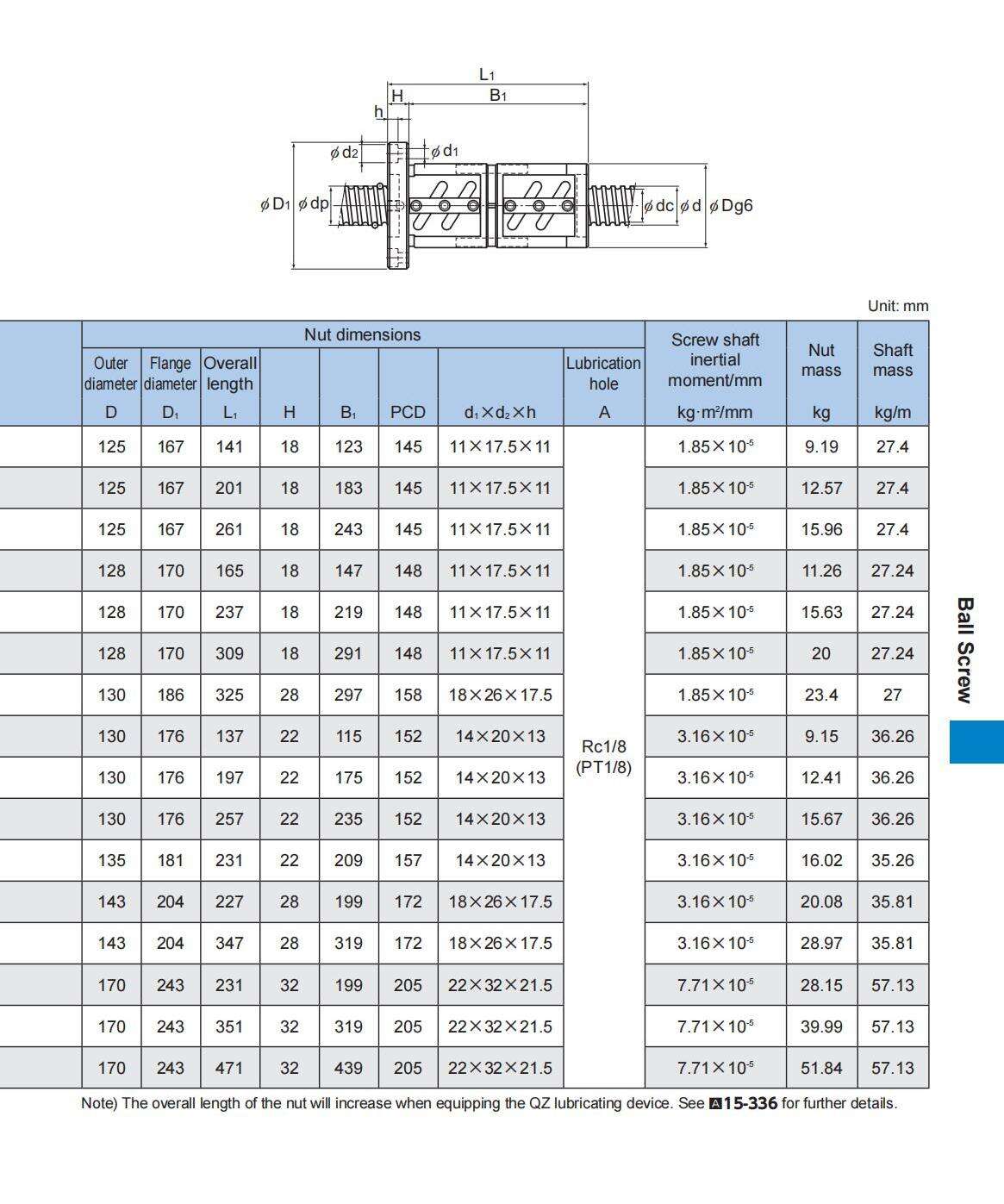

Típusszám |

BNFN 5510-2.5 BNFN 5510-5 BNFN 5510-7.5 BNFN 5512-2.5 BNFN 5512-3 BNFN 5512-3.5 BNFN 5512-5 BNFN 5512-7.5 BNFN 5516-2.5 BNFN 5516-5 BNFN 5520-2.5 BNFN 5520-5 BNFN 6310-2.5 BNFN 6310-5 BNFN 6310-7.5 BNFN 6312A-2.5 BNFN 6312A-5 BNFN 6316-2.5 BNFN 6316-5 BNFN 6320-2.5 BNFN 6320-5 BNFN 7010-2.5 BNFN 7010-5 BNFN 7010-7.5 BNFN 7012-2.5 BNFN 7012-5 BNFN 7012-7.5 BNFN 7020-5 BNFN 8010-2.5 BNFN 8010-5 BNFN 8010-7.5 BNFN 8012-5 BNFN 8020A-2.5 BNFN 8020A-5 BNFN 10020A-2.5 BNFN 10020A-5 BNFN 10020A-7.5 |

Szolgáltatásaink |

Rajzok vagy minták alapján gyártunk termékeket a vevőinknek. |

Termékcsomag |

a. Plasztikos zsák dobozzal vagy fa dobozzal. Bármikor biztosíthatjuk a vásárlónak a szállítási információkat. |

Szállítási idő |

3-7 nap mintavételi rendelésre, 15-20 nap nagykereskedelmi rendelésre. Függ a valóságos szállítási helyzettől. |

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd Minden jog fenntartva