जुलाई 2024 में, शेनझेन के एक नई ऊर्जा बैटरी संयंत्र ने हमसे आपातकालीन संपर्क किया: उनकी सेल स्टैकिंग लाइन के रैक और पिनियन की दक्षता केवल 65% थी, जिससे प्रति घंटे 200 बैटरी का उत्पादन कम हो गया। उनके इंजीनियर ने स्नेहन और संरेखण की जांच की—कोई समाधान नहीं मिला। मैंने 15 मिनट में समस्या ढूंढ ली: 2-मॉड्यूल के रैक को 1.5-मॉड्यूल के पिनियन के साथ जोड़ा गया था। इस अमिलान ने 30% ऊर्जा बर्बाद कर दी और बार-बार जाम की स्थिति उत्पन्न की। मात्र 2 घंटे की मरम्मत के बाद दक्षता बढ़कर 95% हो गई।

रैक और पिनियन की दक्षता केवल 'विफलता से बचना' नहीं है—इसका अर्थ है कम ऊर्जा के साथ अधिक उत्पादन, कम रुकावटें और कम रखरखाव। YOSO MOTION के 11 वर्षों के ट्रांसमिशन इंजीनियर के रूप में, मैंने 250 से अधिक प्रणालियों (नई ऊर्जा, भारी मशीनरी, सटीक इलेक्ट्रॉनिक्स) को अनुकूलित किया है। अधिकांश कारखाने छोटी, ठीक की जा सकने वाली गलतियों के कारण 20-30% दक्षता खो देते हैं। यहाँ 5 सिद्ध तरकीबें, 2024 के परिणाम और त्वरित उन्नयन के लिए एक नि: शुल्क चेकलिस्ट दी गई है।

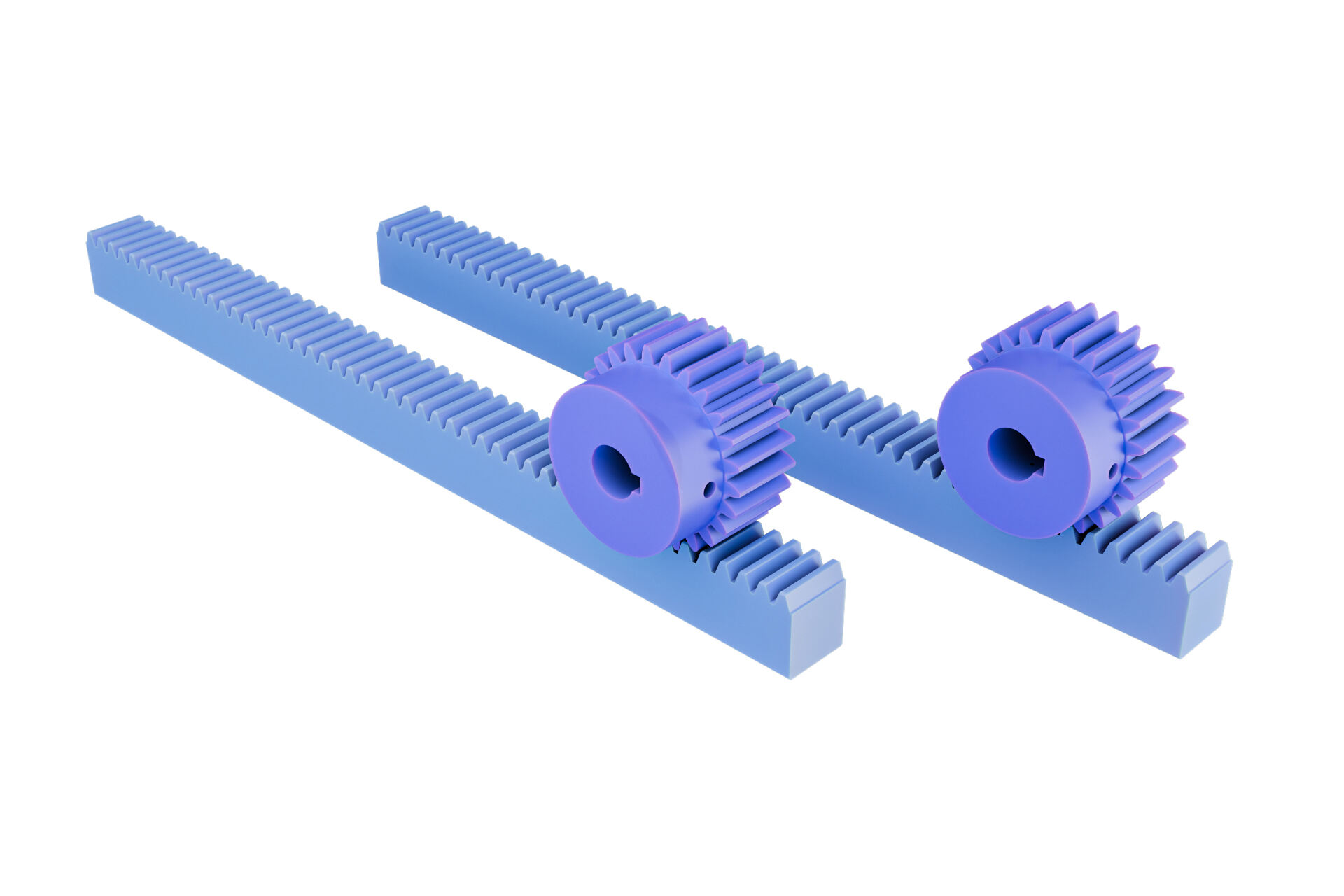

तरकीब 1: मॉड्यूल और दांत प्रोफाइल को सुमेलित करें (दक्षता को नष्ट करने वाला #1 अनजांचा कारक)

मॉड्यूल में अमेल चुपचाप दक्षता को खत्म कर देता है। मार्च 2024 में चांगचुन के एक भारी मशीन टूल संयंत्र को भी यही समस्या थी: एक 3-मॉड्यूल रैक को एक "यूनिवर्सल" 2.5-मॉड्यूल पिनियन के साथ जोड़ा गया था। कटिंग गति 80मिमी/मिनट पर सीमित, मोटर ने 20% अतिरिक्त धारा खींची। वे 3 महीने तक मोटर को दोषी ठहराते रहे—जब तक कि उन्हें अमेल का पता नहीं चला।

समाधान महत्वपूर्ण लेकिन सरल था: हमने रैक के दांत प्रोफाइल के अनुरूप बनाने के लिए यूनिवर्सल पिनियन को YOSO के 3-मॉड्यूल कठोर पिनियन (HRC60) से बदल दिया। एक टूथ कॉन्टैक्ट चेकर ने 90% मेशिंग की पुष्टि की (पहले की तुलना में 60%)। एक सप्ताह के भीतर, कटिंग गति 120मिमी/मिनट तक पहुंच गई, मोटर धारा में 22% की कमी आई, और उपकरण के जीवन में 40% की वृद्धि हुई। शेनझेन के कारखाने ने भी इसी तरह के लाभ देखे: बैटरी स्टैकिंग गति 800 से बढ़कर 1,050 इकाई/घंटा हो गई।

त्वरित जांच : रैक के मॉड्यूल को मापने के लिए कैलिपर का उपयोग करें (10 दांतों के बीच की दूरी ÷ 10)। पिनियन के मॉड्यूल से बिल्कुल मेल खाएं। उच्च दक्षता के लिए, YOSO के मानक "पूर्ण-गहराई वाले दांत प्रोफाइल" का चयन करें (संशोधित प्रोफाइल की तुलना में 25% अधिक मेशिंग क्षेत्र)।

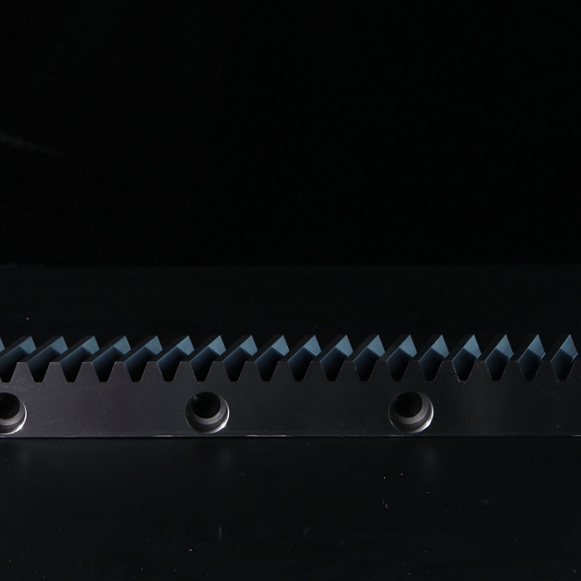

हैक 2: हेलिकल रैक में अपग्रेड करें (अधिक शांत + अधिक शक्ति के बिना 15% तेज)

सीधे-दांत वाले रैक सस्ते होते हैं लेकिन उच्च गति के लिए अक्षम होते हैं। एक डोंगगुआन पrecision इलेक्ट्रॉनिक्स फैक्ट्री ने अप्रैल 2024 में यह बात सीखी: उनके 0.8मी/सेकंड वाले पीसीबी ड्रिल के सीधे-दांत वाले रैक ने प्रतिदिन 10 मिनट तक जाम की समस्या पैदा की। शोर का स्तर 85dB तक पहुँच गया—कर्मचारियों को कान की सुरक्षा की आवश्यकता थी। उन्हें लगा कि गति और शोर अपरिहार्य थे—जब तक हमने रैक नहीं बदला।

हमने YOSO के YR100 हेलिकल रैक (30° दांत का कोण) को स्थापित किया। हेलिकल दांत धीरे-धीरे एक दूसरे में फिट होते हैं (सीधे दांतों के अचानक संपर्क के विपरीत), जिससे जाम पूरी तरह खत्म हो गए और शोर 62dB तक कम हो गया। सबसे अच्छी बात यह थी: ड्रिलिंग की गति 0.92मी/सेकंड तक पहुँच गई बिना मोटर अपग्रेड के —घर्षण में कमी से 15% दक्षता मुक्त हुई। जून तक, प्रतिदिन का डाउनटाइम 2 मिनट तक गिर गया, पीसीबी उत्पादन में 12% की वृद्धि हुई।

कब अपग्रेड करें : जिन प्रणालियों में गति ≥0.5मी/सेकंड या शोर >75dB हो, उनमें हेलिकल रैक तुरंत लाभ देते हैं। ये सीधे-दांत वाले रैक की तुलना में 20% अधिक महंगे होते हैं लेकिन 1-2 महीने में अपनी लागत वसूल लेते हैं (डोंगगुआन ने लागत 6 सप्ताह में वसूल कर ली)।

हैक 3: सटीक ग्राउटिंग (0.1मिमी संरेखण = 20% कम ऊर्जा उपयोग)

अधिकांश कारखाने रैक को सीधे फ्रेम पर बोल्ट करते हैं—खराब माउंटिंग के कारण संरेखण में त्रुटि और ऊर्जा की बर्बादी होती है। मई 2024 में वूशी के एक ऑटोमोटिव चेसिस फैक्ट्री को यही समस्या थी: 2 सप्ताह की वेल्डिंग के बाद रैक 0.15मिमी तक खिसक गया, जिससे मोटर लोड में 20% की वृद्धि हुई। प्रति चेसिस वेल्डिंग चक्र समय 45 सेकंड से बढ़कर 55 सेकंड हो गया, और रैक के दांत असमान रूप से घिस गए।

हमने फ्रेम के अंतराल को भरने के लिए YOSO के G-900 उच्च-शक्ति एपॉक्सी ग्राउट का उपयोग किया, जिससे संरेखण 0.03मिमी के भीतर बना रहा। स्थापना के दौरान सीधापन सत्यापित करने के लिए लेजर उपकरण का उपयोग किया गया। परिणाम: मोटर लोड में 21% की कमी, चक्र समय वापस 45 सेकंड पर आ गया, और रैक के घिसाव की दर 50% धीमी हो गई। त्वरित चक्र के कारण कारखाने ने प्रति माह श्रम लागत में 8,000 डॉलर की बचत की।

ग्राउटिंग नियम : भारी भार (≥5 टन) या उच्च गति (≥0.8मी/से) वाली प्रणालियों के लिए, ग्राउटिंग अनिवार्य है। इसे छोड़ देने पर घर्षण/संरेखण त्रुटि के कारण 15-20% दक्षता की हानि होगी।

हैक 4: वातावरण-विशिष्ट लुब्रिकेंट्स का उपयोग करें (अब एक-ग्रीस-सभी-के-लिए नहीं)

सामान्य चिकनाई दक्षता बर्बाद कर देती है। जून 2024 में एक गुआंगज़ौ लॉजिस्टिक्स भंडारण में मानक लिथियम ग्रीस का उपयोग किया गया: धूल चिपक गई, एक क्षरक पेस्ट बनाते हुए जिसने घर्षण को 35% तक बढ़ा दिया। सॉर्टिंग रोबोट की गति 1.2 से घटकर 0.9मी/से हो गई, और रैक को हर 3 दिन में साफ करने की आवश्यकता थी।

हमने योसो के धूल-प्रतिरोधी चिकनाई वाले वाईएल-400 (सिंथेटिक, एंटी-एडहेसिव एडिटिव्स धूल को विकर्षित करते हैं) में स्विच किया और चिकनाई अंतराल को 3 से बढ़ाकर 14 दिन कर दिया। घर्षण में 40% की कमी आई, रोबोट की गति वापस 1.2मी/से हो गई, और सफाई के समय में 90% की कमी आई। प्रति घंटे सॉर्टिंग क्षमता में 300 पैकेज की वृद्धि हुई।

चिकनाई मिलान गाइड : धूल भरा (लॉजिस्टिक्स/सीएनसी) → वाईएल-400; गीला (पीसीबी/कूलेंट) → वाईएल-500; उच्च-तापमान (वेल्डिंग/फोर्जिंग) → वाईएल-600 (अधिकतम 200°C)। सही ग्रीस घर्षण को 30-40% तक कम कर देती है।

हैक 5: बैकलैश एडजस्टमेंट किट्स जोड़ें (परिशुद्धता = कम पुनः कार्य)

0.05 मिमी से अधिक बैकलैश सटीकता को नष्ट कर देता है और फिर से काम करने की आवश्यकता होती है, जिससे दक्षता खत्म हो जाती है। जुहाई 3C कैमरा फैक्ट्री में जुलाई 2024 में 0.1 मिमी बैकलैश था: मॉड्यूल्स के 15% असफल संरेखण, जिसके कारण प्रतिदिन 2 घंटे का मैनुअल रीवर्क आवश्यक था।

हमने YOSO का बैकलैश समायोजन किट (प्रिसिजन रैक्स के साथ शामिल) स्थापित किया, जिससे बैकलैश 0.02 मिमी तक कम हो गया। हमने साप्ताहिक 5-मिनट की जाँच के लिए समायोजन बोल्ट्स को चिह्नित किया। रीवर्क 2% तक गिर गया, प्रतिदिन रीवर्क समय 1.5 घंटे कम हो गया, और कोई अतिरिक्त श्रम के बिना कैमरा मॉड्यूल आउटपुट 10% बढ़ गया।

बैकलैश सीमा : प्रिसिजन (3C/कैमरा) → ≤0.03 मिमी; भारी मशीनरी (स्टैम्पिंग) → ≤0.08 मिमी; सामान्य (पैकेजिंग) → ≤0.1 मिमी। इन्हें पार करने पर रीवर्क/दक्षता हानि तेजी से बढ़ जाती है।

YOSO की दक्षता ऑडिट: हम आपकी बर्बादी मुफ्त में ढूंढते हैं

अधिकांश फैक्ट्रियां अपनी दक्षता हानि के बारे में नहीं जानतीं—जब तक हम उन्हें नहीं दिखाते। हमारी मुफ्त 30 मिनट की दक्षता ऑडिट में शामिल है:

-

साइट पर/आभासी जाँच : रैक-पिनियन मिलान, संरेखण, चिकनाई, बैकलैश का निरीक्षण (कोई डाउनटाइम नहीं)।

-

दक्षता रिपोर्ट : वर्तमान दक्षता और संभावित लाभ की गणना करें (उदाहरण के लिए, "मॉड्यूल मिसमैच ठीक करें = 15% तेज़ गति").

-

प्राथमिकता वाली ठीक करने की सूची : आरओआई के आधार पर ठीक करने की सूची को रैंक करें (उदाहरण के लिए, "बैकलैश समायोजन 1 सप्ताह में खुद को वसूल लेता है").

शेन्ज़ेन फैक्ट्री के 20 मिनट के ऑडिट ने मॉड्यूल मिसमैच की पहचान की और 30% दक्षता में सुधार का अनुमान लगाया। उन्होंने अगले दिन ही इसे ठीक कर दिया और तुरंत परिणाम देखे।

क्या आप अपनी रैक दक्षता में 30% की वृद्धि करने के लिए तैयार हैं?

शेन्ज़ेन फैक्ट्री ने 2 घंटे में 95% दक्षता प्राप्त कर ली। डोंगगुआन ने डाउनटाइम में 80% की कमी की। इन लाभों के लिए महंगे अपग्रेड की आवश्यकता नहीं होती—बस छोटी, नज़रअंदाज़ की गई गलतियों को ठीक करना होता है।

यदि आपकी रैक धीमी, शोरगुल भरी या ऊर्जा-लालची है, तो अपव्यय ढूंढ़ते हैं। हमें अपना अनुप्रयोग (उदाहरण के लिए, नई ऊर्जा बैटरी स्टैकिंग) और वर्तमान आउटपुट (उदाहरण के लिए, 800 इकाई/घंटा) भेजें। हम 24 घंटे के भीतर एक नि: शुल्क दक्षता अनुमान और "रैक दक्षता चेकलिस्ट" भेजेंगे।

कोई दायित्व नहीं—हम बस आपकी प्रणाली की क्षमता को अधिकतम करना चाहते हैं। अपव्यय को उत्पादकता में बदलने के लिए आज ही हमारी दक्षता टीम से संपर्क करें।

विषय सूची

- तरकीब 1: मॉड्यूल और दांत प्रोफाइल को सुमेलित करें (दक्षता को नष्ट करने वाला #1 अनजांचा कारक)

- हैक 2: हेलिकल रैक में अपग्रेड करें (अधिक शांत + अधिक शक्ति के बिना 15% तेज)

- हैक 3: सटीक ग्राउटिंग (0.1मिमी संरेखण = 20% कम ऊर्जा उपयोग)

- हैक 4: वातावरण-विशिष्ट लुब्रिकेंट्स का उपयोग करें (अब एक-ग्रीस-सभी-के-लिए नहीं)

- हैक 5: बैकलैश एडजस्टमेंट किट्स जोड़ें (परिशुद्धता = कम पुनः कार्य)

- YOSO की दक्षता ऑडिट: हम आपकी बर्बादी मुफ्त में ढूंढते हैं

- क्या आप अपनी रैक दक्षता में 30% की वृद्धि करने के लिए तैयार हैं?

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

BE

BE

KA

KA

LA

LA

MY

MY

TG

TG

UZ

UZ