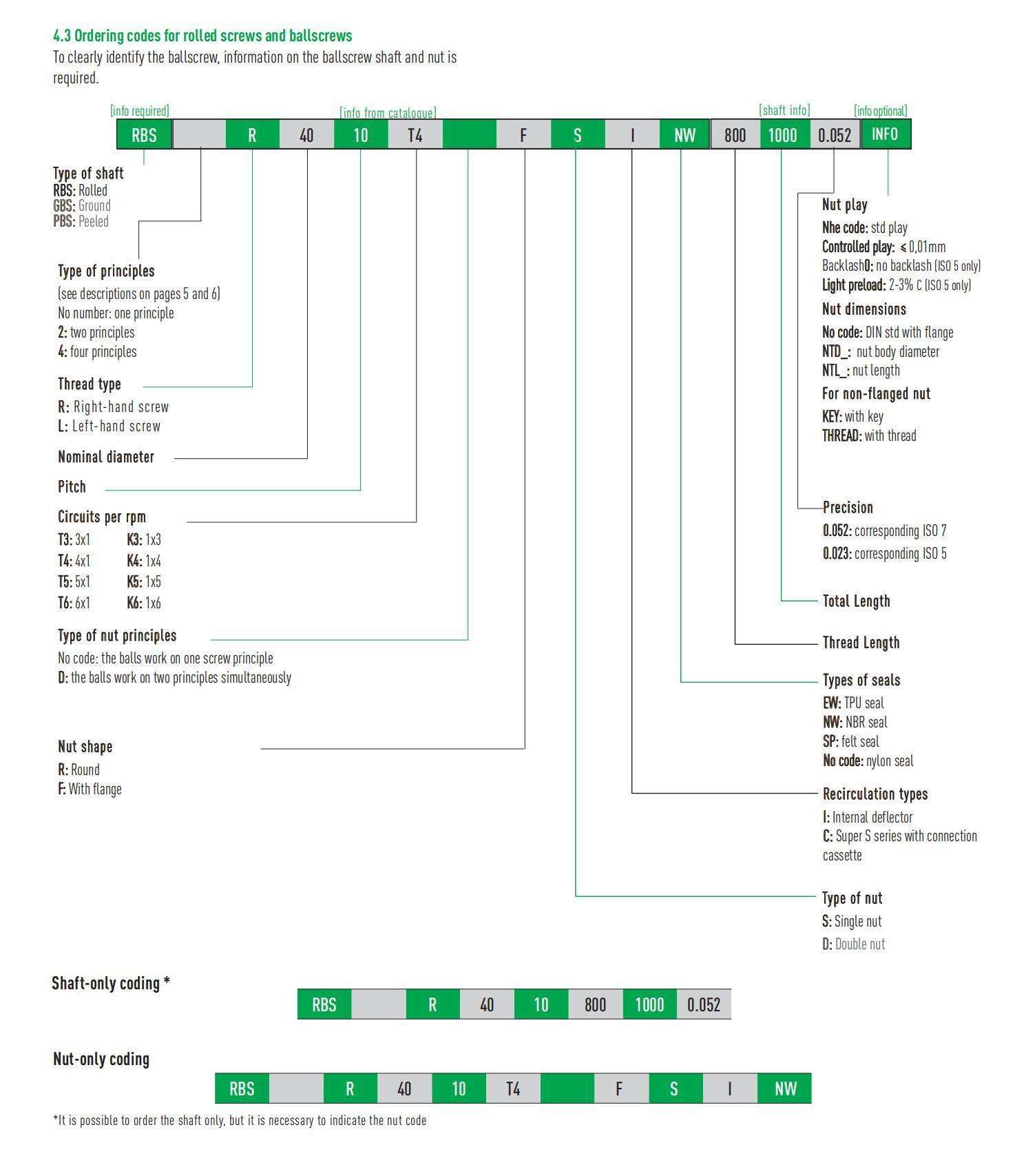

Signification du modèle :

« R » : Indique une vis à billes tournant à droite.

« 16 » : Représente un diamètre nominal de 8 mm.

« 10 » : Se réfère à un pas de vis de 2,5 mm, ce qui signifie que l'écrou se déplace de 2,5 mm le long de l'axe de la vis à chaque rotation de celle-ci.

« T3 » : 3×1

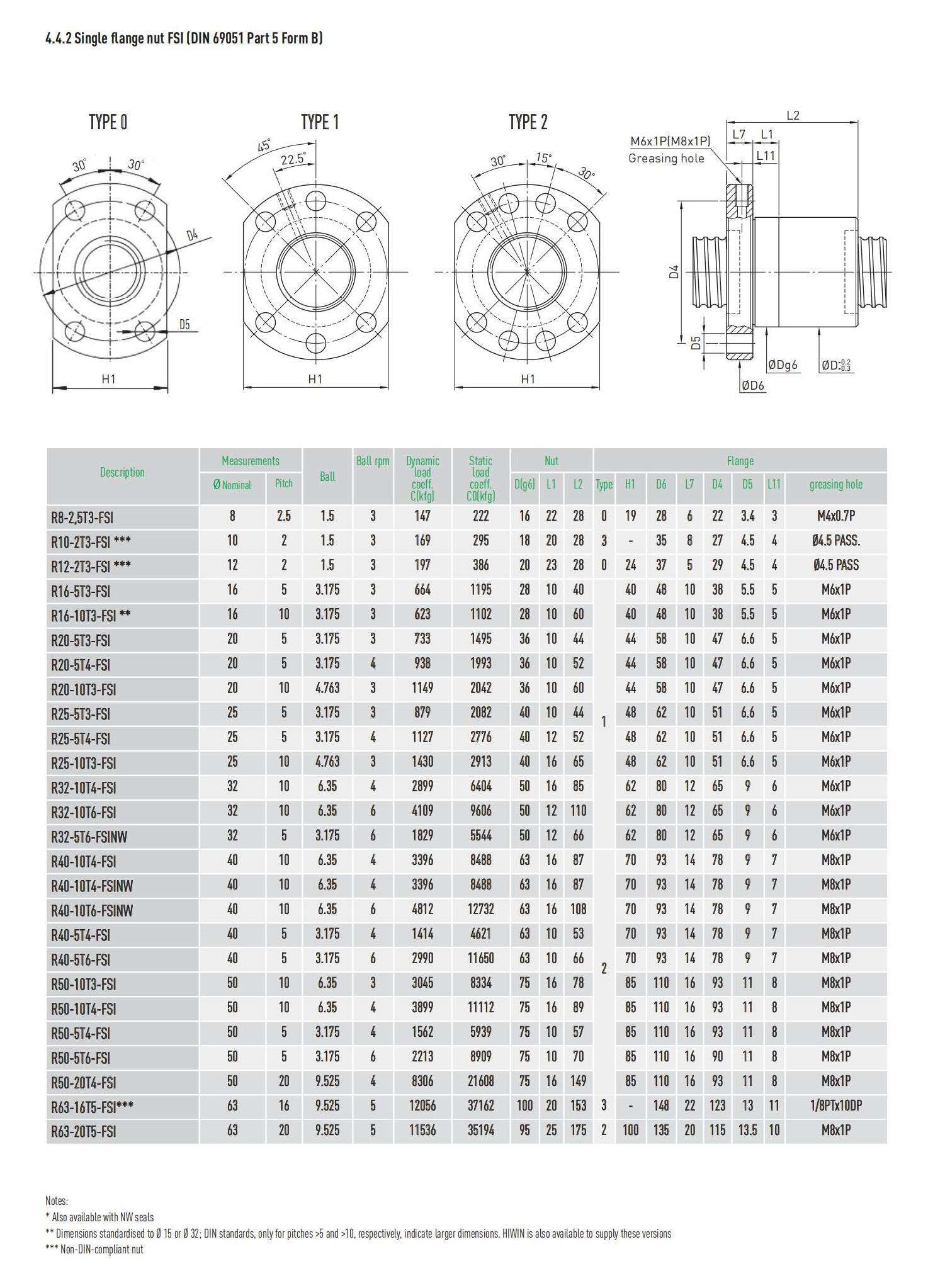

« FSI » : « F » : Écrou à bride, « S » : Écrou simple, et « I » : Recirculation interne.

Afin de tirer pleinement parti des performances des vis à billes HIWIN R16-10T3-FSI, une méthode d'installation correcte est essentielle. Avant l'installation, assurez-vous que la précision d'usinage du support et du logement de l'écrou répond aux exigences d'assemblage, afin d'éviter un fonctionnement défectueux dû à l'excentricité ou au désalignement. L'FSI possède une structure compacte, il est donc recommandé d'utiliser des outils spéciaux pour faciliter l'alignement de l'axe central afin d'éviter les concentrations de contraintes pendant l'assemblage. En outre, après l'installation de la vis, il est nécessaire de vérifier si l'écrou se déplace librement et s'il y a blocage ou bruit anormal. Si le système exige des mouvements répétitifs précis, il est recommandé d'utiliser une structure de précharge pour éliminer le jeu. Dans des situations à charge élevée ou à grande vitesse, il convient de choisir judicieusement le mode de lubrification. Il est recommandé d'utiliser une graisse de haute qualité et de la compléter régulièrement afin d'éviter l'usure due au frottement sec sur la surface de la vis. Un assemblage et un réglage normalisés permettent de maximiser la durée de vie de la vis à billes FSI et d'améliorer la stabilité globale du système.

Copyright © Jingpeng Machinery&Equipment(Shanghai) Co., Ltd Tous droits réservés