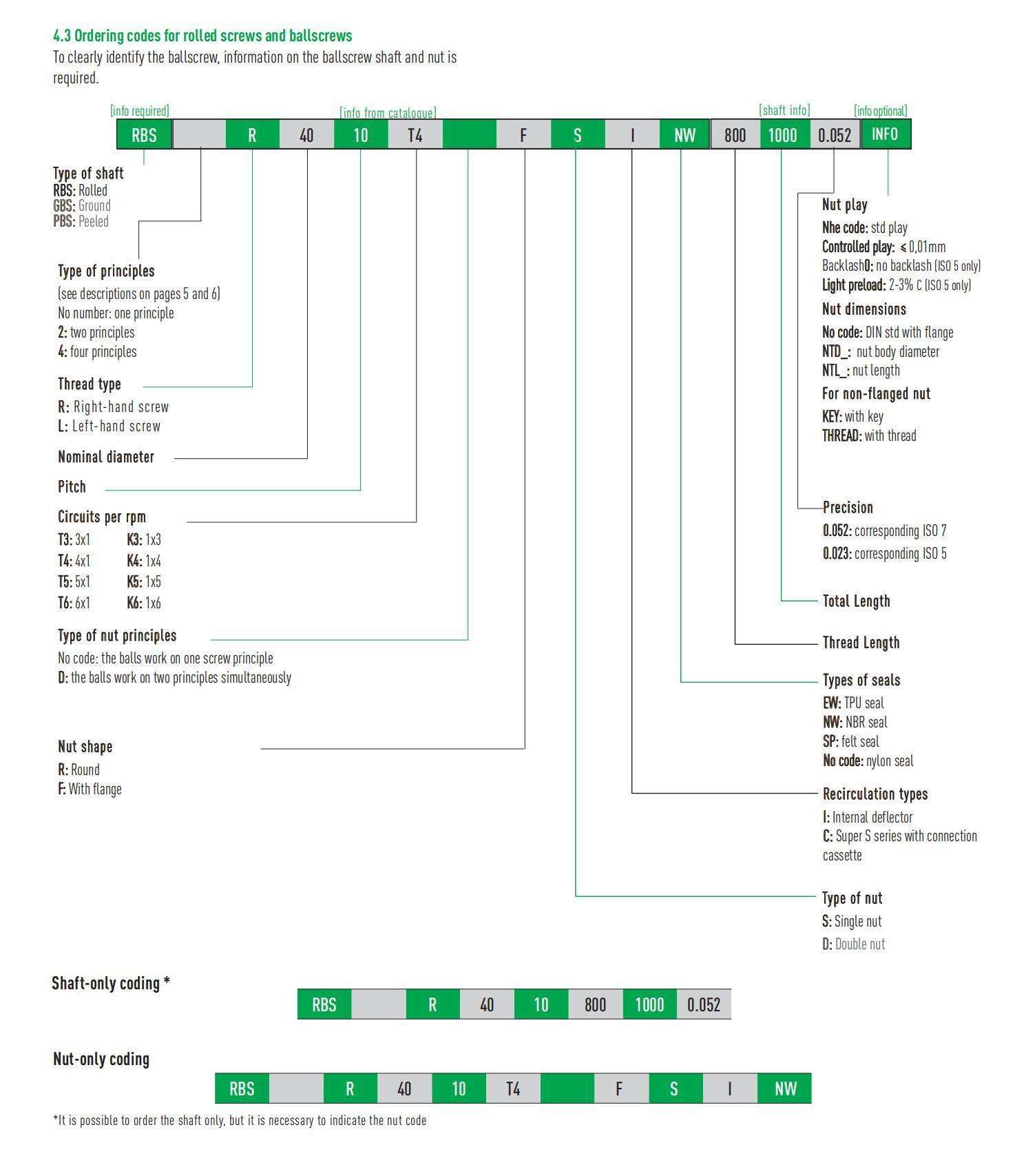

توضیح مدل:

«R»: نشاندهنده پیچ گویی چرخشی دست راست است.

"40": قطر اسمی 40 میلیمتر را نشان میدهد.

«10»: به پیشروی 10 میلیمتری اشاره دارد، یعنی مهره در هر چرخش پیچ، 10 میلیمتر در امتداد محور پیچ حرکت میکند.

“T4”: 4×1

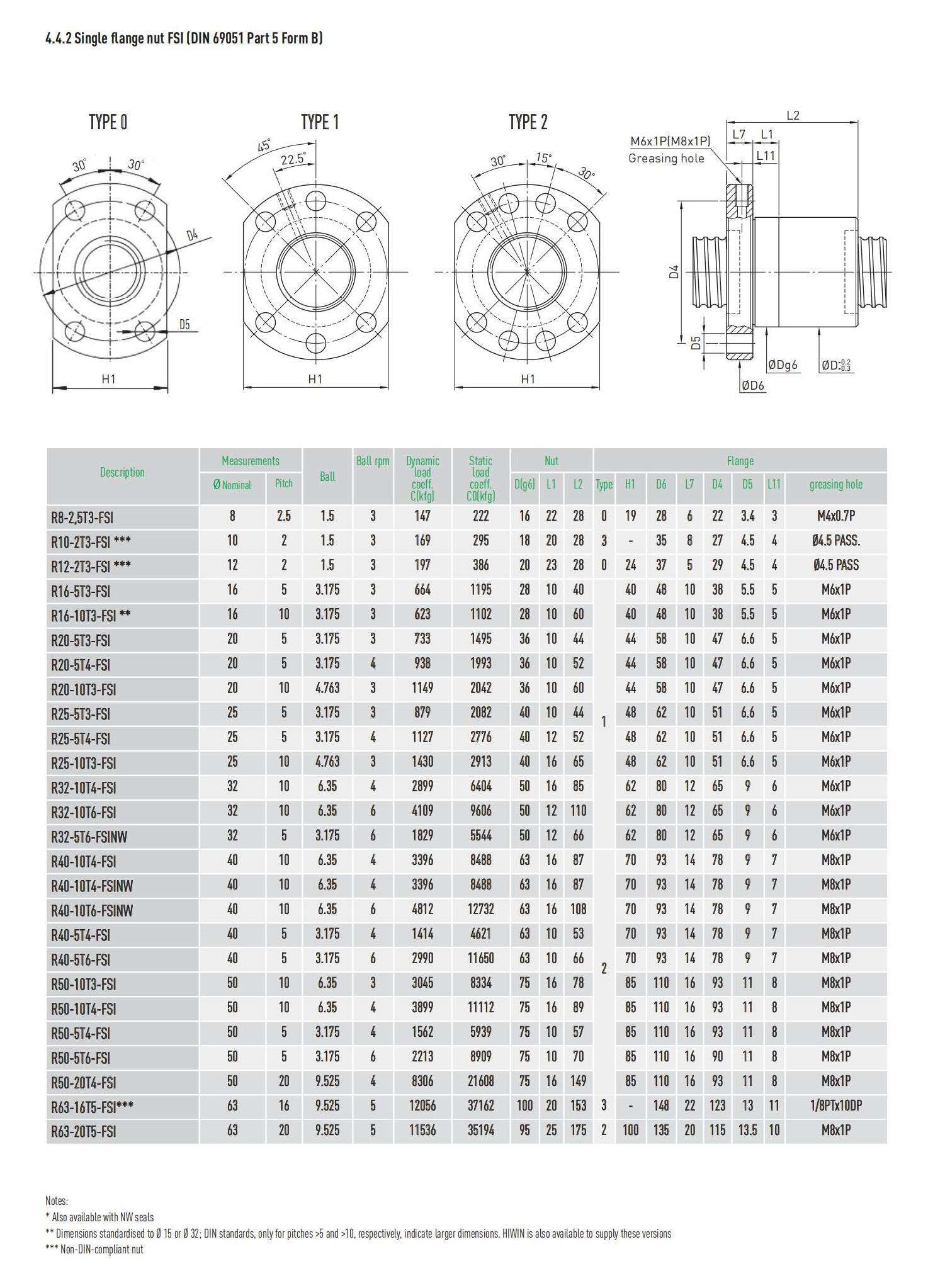

“FSI”: “F”: مهره دارای فلنج، “S”: مهره تکی، و “I”: بازگردانی داخلی.

کاربرد HIWIN مدل R40-10T4-FSI-0.05

(1) پیچ گویای باید تمیز نگه داشته شود و از ورود ذرات خارجی به مهره جلوگیری شود.

(2) از ضربه زدن دلخواه خودداری کنید و از بروز آسیب به ظاهر آن جلوگیری کنید.

(3) سطح نصب باید کاملاً تمیز و بدون هرگونه ناهمواری باشد.

(4) تحملهای مناسب و کالیبراسیون دقیق.

(5) روانکاری مناسب.

(6) پیچ را از مهره جدا نکنید.

(7) بهتر است دستگاههای ضد برخورد را در هر دو انتهای پیچ نصب کنید تا از آسیب دیدن پیچ گویی در اثر حرکت بیش از حد م stroke جلوگیری شود.

(8) از یک پوشش محافظ برای حفاظت از پیچ گویی و جلوگیری از ورود گرد و غبار استفاده کنید.

کپی رایت © Jingpeng Machinery&Equipment(Shanghai) Co., Ltd تمامی حقوق محفوظ است.