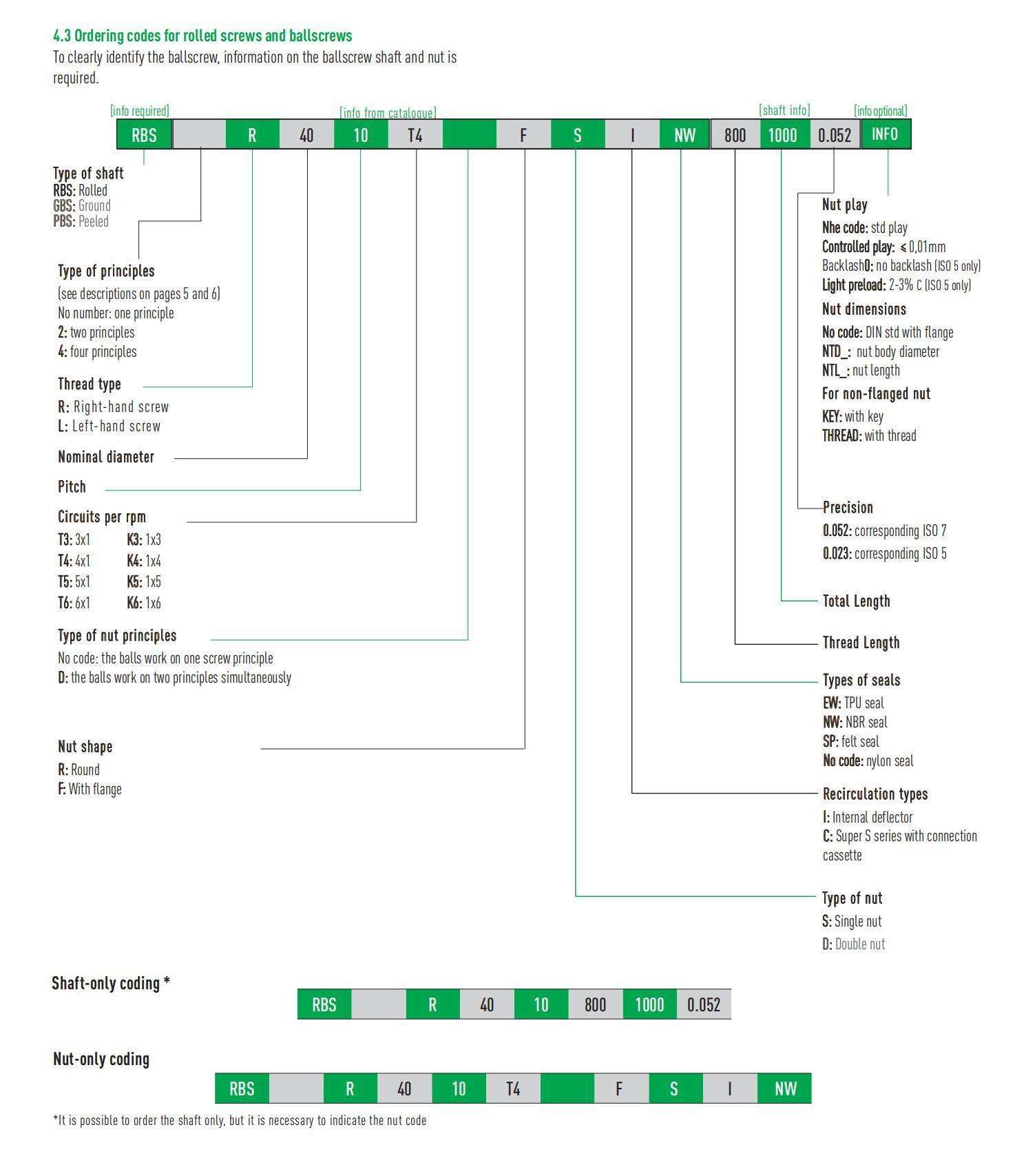

Model Meaning:

“R”: Yn nodi sglewrowiad bâl â cheg ar y de.

'16': Yn cynrychioli diamedr enwol o 8mm.

“10”: Yn cyfeirio at arwyneb 2.5mm, sy'n golygu bod y frech yn symud 2.5mm ar hyd eilir y sgrŵ ar gyfer pob troad sgrŵ.

“T3”: 3×1

“FSI”: “F”: Drennyn agored â flange, “S”: Drennyn sengl, a “I”: Ad-droeddieithreiddiad mewnol.

Er mwyn gwella pherfformiad sglewrau'r HIWIN R16-10T3-FSI, mae angen defnyddio dull gosod cywir. Cyn gosod, gwiriwch fod cywiriad y gosodiad cymorth a'r gosodiad rhwyd yn bodloni gofynion casglu er mwyn osgoi gweithrediad gwael oherwydd anghyfoedrwydd neu ddiffyg cydraddoldeb. Mae gan FSI strwythur gwmwl, ac yn argymell ddefnyddio teclyn arbennig i'ch helpu i leoli'r llinell ganolog er mwyn osgoi crynodiad tensiwn yn ystod y casglu. Ychwanegol, ar ôl gosod y sglew, mae'n rhaid gwirio a yw'r rhwyd yn symud yn hyblyg a pha yw os oes unrhyw glocio neu swn annhebygol. Os yw'r system yn gofyn am symudiad ailadroddol o uchelgeiriogrwydd, mae'n argymell ddefnyddio strwythur rhag-les i ddileu'r bwlch. Mewn sefyllfaoedd llawn-llwyth neu gyflymder uchel, dylech chi ddewis y dull olewi yn resymol. Mae'n argymell ddefnyddio olygion o ansawdd uchel a'u ychwanegu'n rheolaidd i'ch atal rhag sglewrio ar sych sy'n niweidio ar wyneb y sglew. Trwy osod a chyflunio'n safonol, gellir cynyddu oes gwasanaeth sglew FSI a hybu sefydlogrwydd y system yn gyffredinol.

Hawlfraint © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd. Cedwir yr holl hawliau