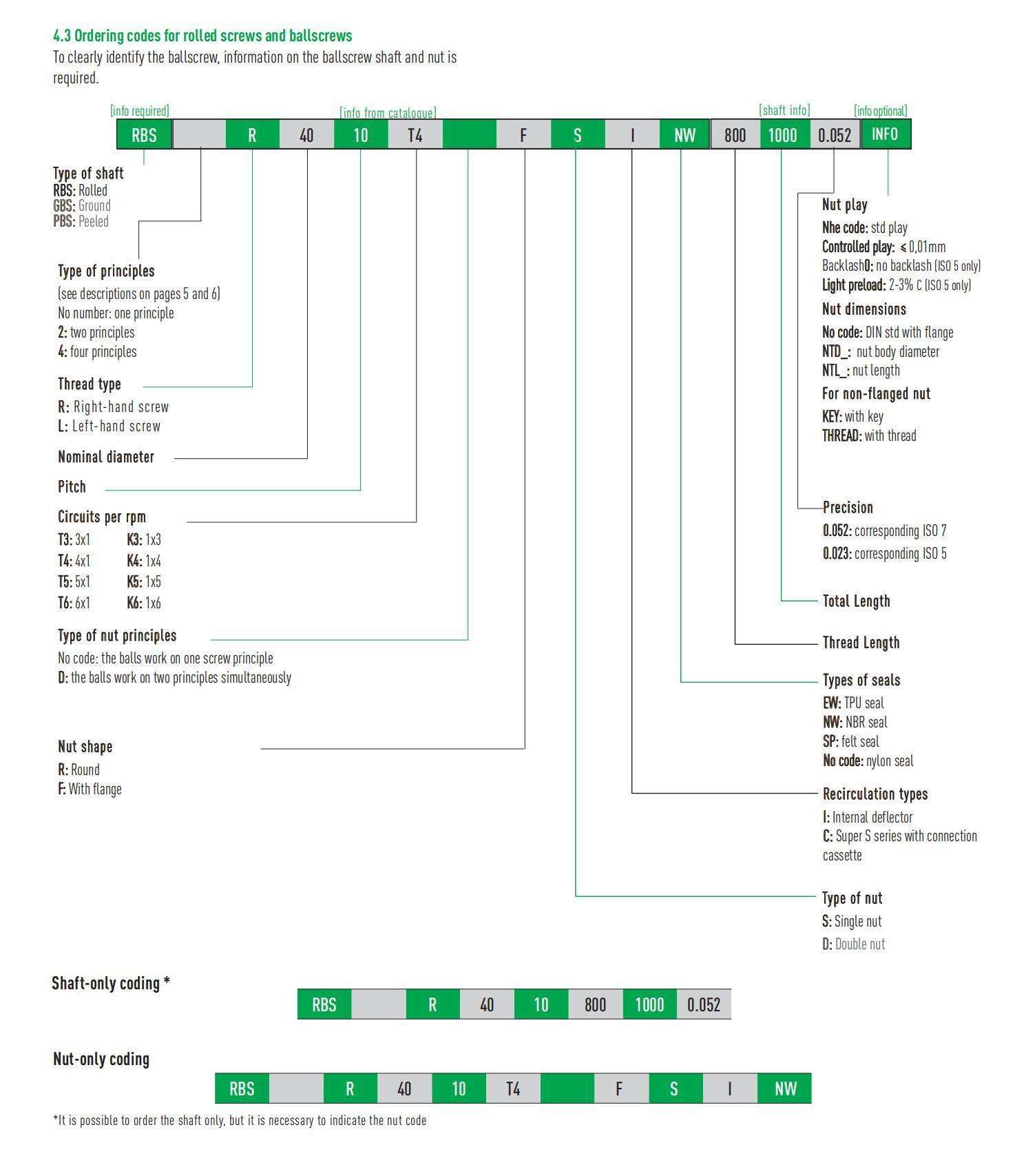

Význam modelu:

„R“: Označuje kuličkový šroub s pravotočivým závitem.

„25“: Znamená jmenovitý průměr 25 mm.

„5“: Označuje stoupání 2,5 mm, což znamená, že matka postoupí o 5 mm podél osy šroubu při každé otáčce šroubu.

„T3“: 3×1

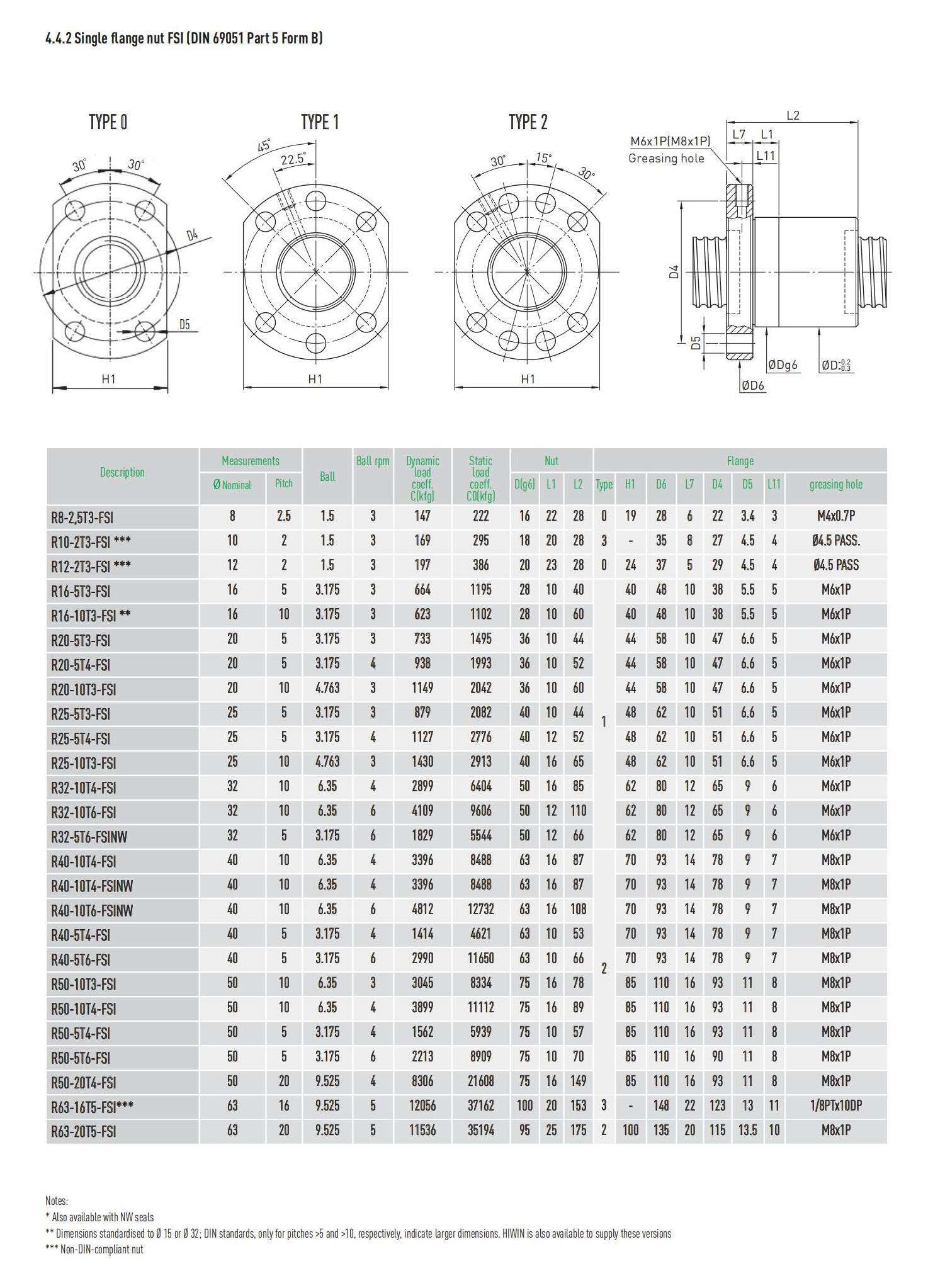

„FSI“: „F“: Matka s přírubou, „S“: Jednoduchá matka, „I“: Vnitřní recirkulace.

Při použití kuličkového šroubu HIWIN R25-5T3-FSI je běžná údržba nezbytná pro zachování vysoké přesnosti a dlouhé životnosti. Níže jsou uvedeny body údržby pro kuličkové šrouby řady FSI, které mohou sloužit jako referenční materiál pro většinu průmyslových servisních techniků a nákupčích:

1. Pravidelné mazání

Kontaktní části kuličkového šroubu vyžadují kvalitní mazání, aby se snížilo tření a opotřebení. Doporučuje se pravidelné doplňování vhodného tuku nebo mazacího oleje a úprava frekvence mazání v závislosti na provozní rychlosti, okolní teplotě a zatížení. V suchém nebo prachovém prostředí je třeba zvýšit frekvenci mazání.

2. Čištění povrchu šroubu

Povrch šroubu je třeba udržovat čistý, aby se zabránilo vniknutí prachu, kovových třísek a jiných nečistot do matice, což může způsobit zaseknutí kuličky nebo poškrábání povrchu. Lze jej otřít měkkým hadříkem bez vláken a nečistot, případně použít speciální čisticí prostředek.

3. Ochrana proti rezavění

Je-li šroub FSI nainstalován v prostředí s vysokou vlhkostí, je nutné pravidelně kontrolovat známky rezavění a nanést protirezavěcí olej nebo použít mazivo s ochrannými vlastnostmi proti rezavění.

4. Kontrola provozního stavu

Pravidelně sledujte, zda je zvuk šroubu stabilní a zda nejsou přítomny abnormální vibrace, zasekávání nebo hluk. V případě jakéhokoli poruchového jevu je třeba okamžitě zkontrolovat možné problémy, jako je chyba centrování, vypadávání kuliček nebo porucha mazání.

5. Kontrola utažení a instalace

Zkontrolujte, zda jsou instalační díly, jako je šroubovací upínací sedadlo a zátková matice, uvolněné. Díky vnitřní cirkulační struktuře závisí šroubový hřídel FSI více na stabilním instalačním prostředí, aby byla zajištěna přenosová účinnost.

Pravidelná údržba může nejen prodloužit životnost šroubového hřídele HIWIN FSI, ale také udržet stabilitu a přesnost provozu zařízení. Je to důležitý článek, který nelze v managementu zařízení zanedbat.

Všechna práva vyhrazena © Jingpeng Machinery&Equipment(Shanghai) Co.,Ltd